A mine dual heat source comprehensive heat recovery device and device structure optimization method

A heat recovery device and dual heat source technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as cumbersome and complicated technical solutions, accumulation of return pools, and large water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

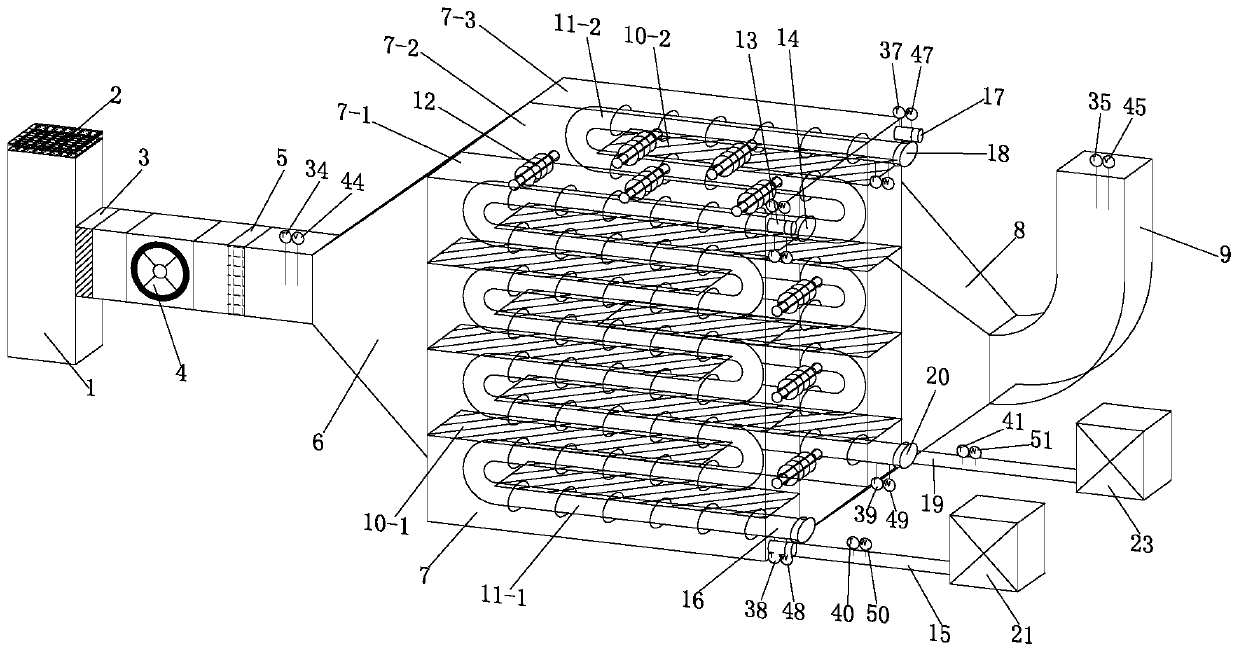

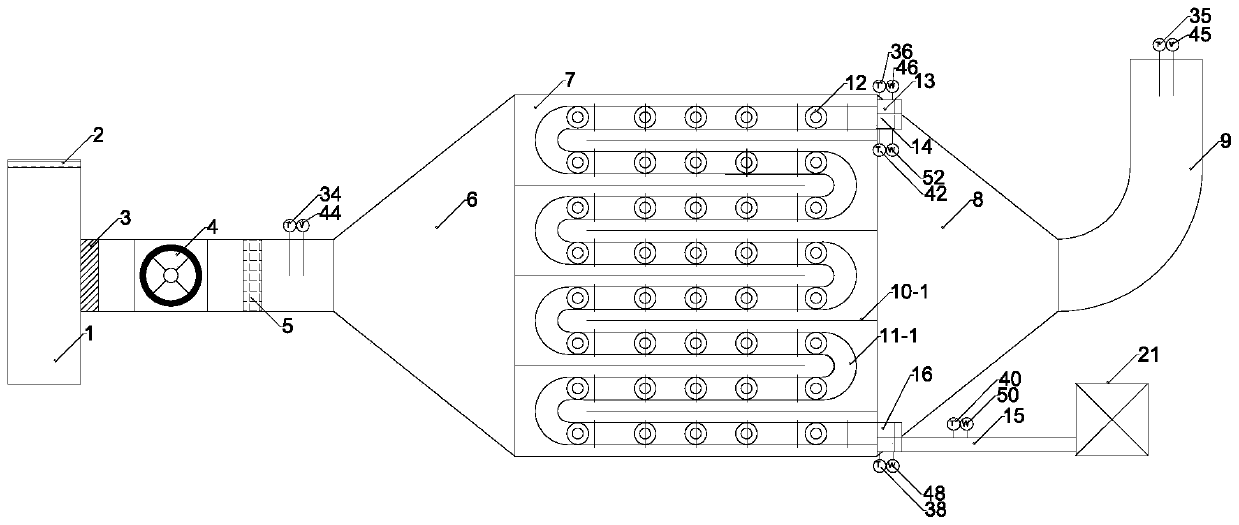

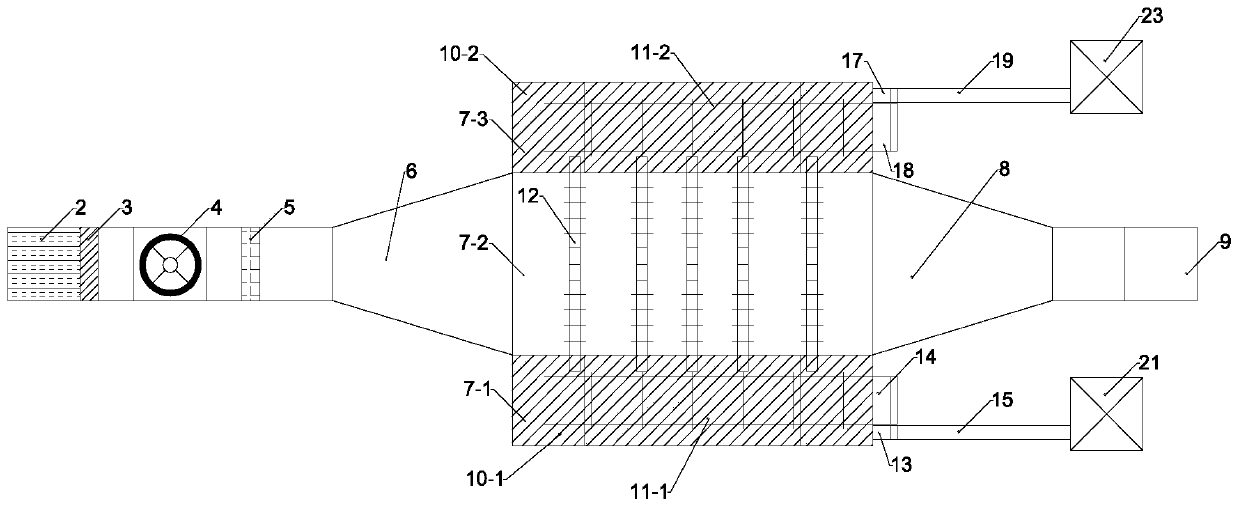

[0110] like Figure 1 ~ Figure 3 As shown, the mine double heat source comprehensive heat recovery device of the present invention includes an air inlet unit, a heat exchange unit and an air outlet unit; the air inlet unit includes a return air shaft 1, and the upper end of the return air shaft 1 is connected with a The butterfly-shaped windshield 2 with wind speed and wind force and dust suppression effect, the side of the return air shaft 1 is connected with a metal filter screen 3 for intercepting the particulate matter in the mine return air and avoiding damage to the fan blades, the metal The rear end of the filter screen 3 is provided with a fan 4 for sucking the mine return air in the return air shaft 1 into the heat exchange box, and the rear end of the fan 4 is provided with a packing layer 5 for improving the turbulence of the mine return air. The rear end of the packing layer 5 is provided with a trumpet-shaped return air diffuser 6; the air outlet unit includes a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com