A multiphase fluid temperature changing device

A temperature-changing device, multiphase fluid technology, applied in tubular elements, lighting and heating equipment, indirect heat exchangers, etc. The effect of high exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

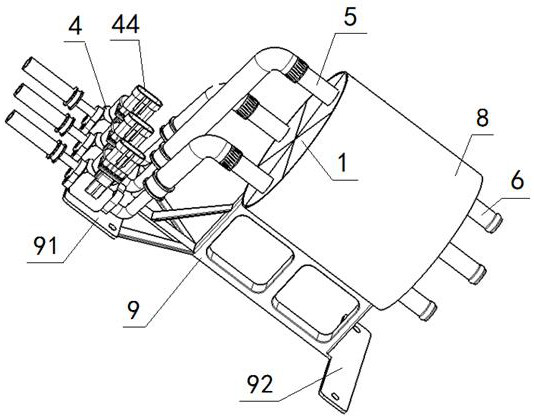

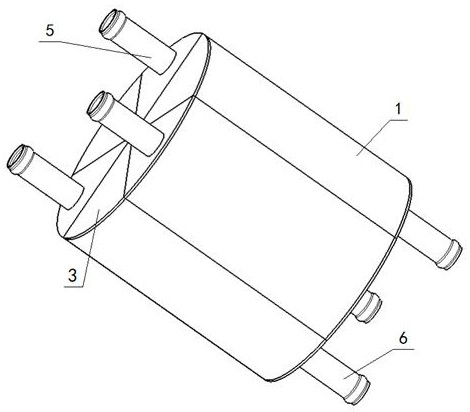

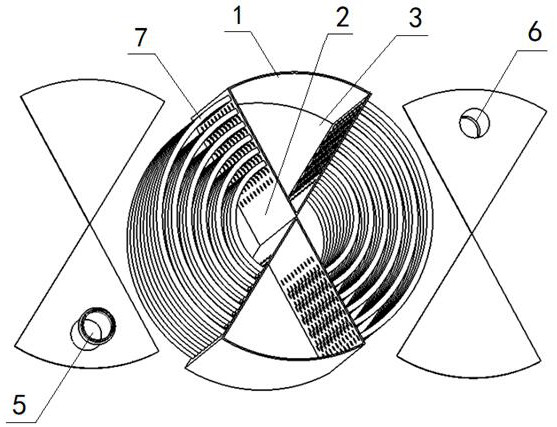

[0091] A multi-phase fluid temperature change device, the temperature change device includes a shell 1, a plurality of partitions 2 and heat exchange pipes 7, the shell 1 is a cylindrical structure, the partition 2 divides the internal space of the shell 1 Equally divided into an even number of fan-shaped sealing chambers 3, at least two heat exchange units are formed inside the temperature-changing device; the two opposite fan-shaped sealing chambers 3 are connected through multiple heat exchange pipes 7, and the two opposite fan-shaped sealing chambers The cavity 3 and the heat exchange pipe 7 connecting the two fan-shaped sealed chambers 3 form a heat exchange unit; the two ends of the heat exchange pipe 7 in the single heat exchange unit are fixedly connected with the partition plate 2 on the corresponding side, and the heat exchange The pipe 7 is located in the fan-shaped sealing cavity 3 between the two partitions 2 connected at its ends; the two opposite fan-shaped seali...

Embodiment 2

[0093] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0094] The partition plate 2 divides the inner space of the housing 1 into six fan-shaped sealed cavities 3, and the six fan-shaped sealed cavities 3 include: a first-phase liquid inlet chamber 31, a second-phase liquid inlet chamber 32, and a three-phase liquid inlet chamber 33. One-phase liquid outlet chamber 34, two-phase liquid outlet chamber 35 and three-phase liquid outlet chamber 36; the electronic valve 4 includes: one-phase electronic valve 41, two-phase electronic valve 42 and three-phase electronic valve 43; The heat exchange pipe 7 includes: a one-phase heat exchange tube 71, a two-phase heat exchange tube 72 and a three-phase heat exchange tube 73; the heat exchange liquid inlet 5 includes: a one-phase heat exchange liquid inlet 51, a two-phase heat exchange Liquid inlet 52 and three-phase heat exchange liquid inlet 53; the heat exchange liquid outlet 6 includes: one-phase heat exc...

Embodiment 3

[0096] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0097] The one-phase heat exchange tubes 71, two-phase heat exchange tubes 72, and three-phase heat exchange tubes 73 are arranged from top to bottom with one layer of one-phase heat exchange tubes 71, one layer of two-phase heat exchange tubes 72, and one layer of three-phase heat exchange tubes. The sequence of the heat pipes 73 is arranged circularly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com