Internal part for reaction or heat exchange equipment

A technology of heat exchange equipment and internal parts, which is applied in the field of heat exchange components, can solve the problems of large footprint, overheating reaction, complex maintenance, etc., and achieve the effects of saving floor space, realizing precise control, and increasing filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

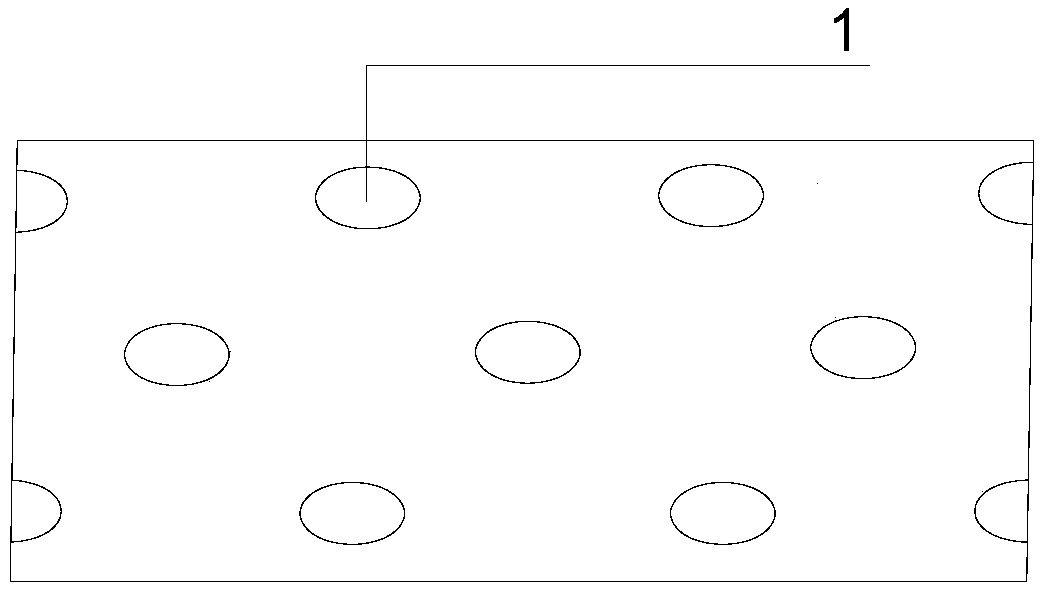

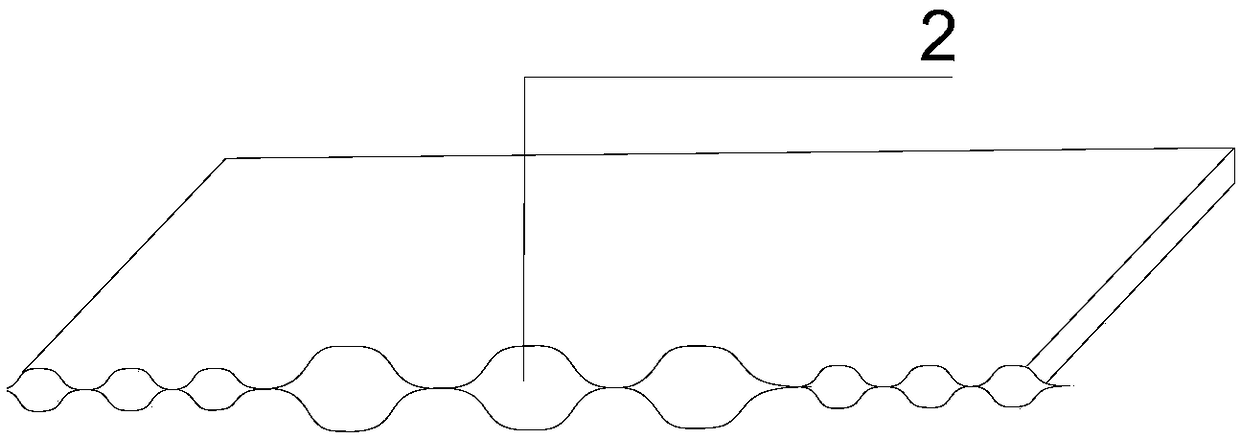

[0035] figure 1 Shown is a structural schematic diagram of an internal part for reaction or heat exchange equipment, which is composed of two metal plates connected by welding points 1 and edge welds, and then high-pressure bubbling to form a heat exchange plate with a layer of chambers right.

[0036] The distance, shape and diameter of the solder joints 1 between the metal plates can be changed according to the different requirements for the flow pattern of the medium in the channel. The welding spot 1 is a welding spot formed by welding corresponding positions of two metal sheets, and the shape of the welding spot includes a circle and a polygon.

[0037] A plurality of welding spots are scattered on the metal sheet, the distance between adjacent welding spots is 20-100 mm, and the diameter of the welding spots is 1-20 mm. The adjustment of the above parameters can change the degree of turbulence and pressure drop of the medium, so as to achieve a good balance between the t...

Embodiment 2

[0043] When the heat exchange inner part is composed of two metal plates with different thicknesses, the cross-sectional view is as follows: Figure 4 As shown, the thickness of one metal sheet is twice the thickness of the other, and the two metal sheets are connected by welding points and edge welds, and then undergo high-pressure bubbling to form a 50mm-high Protrusion 1, the thicker metal plate will remain flat, such a heat exchange plate has been applied to a modular design reactor, thereby reducing the footprint of the reactor and enhancing the compactness of the reactor. This modularization The design can be 3 to 5 percent more compact than a non-modular design.

Embodiment 3

[0045] When the heat exchange internal part is composed of three metal plates, its cross-sectional view is as follows: Figure 5 As shown, the middle metal plate is thicker, and the metal plates on both sides are thinner. After high-pressure bubbling, the middle metal plate remains flat, and the metal plates on both sides protrude outward, with a height of 50mm, forming a double-chamber heat exchange. Internal parts, which can realize simultaneous heat exchange of two media, are applied to dual heat source heat pumps and natural cooling systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com