Orifice plate flow meter throttling device

A technology of orifice flowmeter and throttling device, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., and can solve the problem of pipe pipe, liquid impact, and decrease in measurement accuracy of orifice flowmeter and other problems to achieve the effect of improving measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

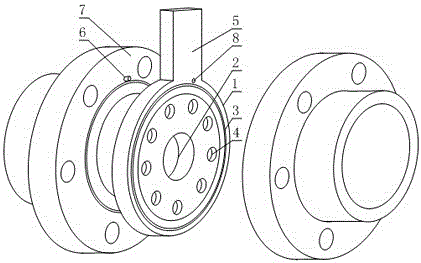

[0021] Such as figure 1 As shown, a throttling device for an orifice flowmeter includes two connecting flanges 7 arranged oppositely and an annular orifice plate body 1 arranged between the connecting flanges 7 , the orifice plate body 1 The center is also provided with a circular center hole 2, and also includes a permeable hole 4 arranged between the outer edge of the orifice plate body 1 and the center hole 2, the permeable hole 4 runs through both sides of the orifice plate body 1, and the orifice plate The outer edge of the body 1 is also fixedly connected with a strip-shaped installation handle 5, the length direction of the installation handle 5 is located in the radial direction of the orifice plate body 1, and the side of the orifice plate body 1 is also provided with a positioning hole 8 , at least one connecting flange 7 is provided with a positioning pin 6 matched with the positioning hole 8 .

[0022] In this embodiment, the orifice plate body 1 is used for clip-...

Embodiment 2

[0024] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, in order to facilitate the symmetry of the flow velocity of the gaseous fluid at each point on the pipeline cross-section relative to the centerline of the orifice plate body 1, and to facilitate the accuracy of the orifice flowmeter measurement, there are more than one permeable holes 4, and the permeable holes 4 are in the The orifice plate body 1 is evenly distributed in a ring shape relative to the centerline of the orifice plate body 1 .

[0025] In order to facilitate the static sealing effect between the orifice plate body 1 and the corresponding connecting flange, both sides of the orifice plate body 1 are provided with annular tenons and grooves 3 .

[0026] In order to weaken the impact of the friction between the impurity and the orifice plate body 1 on the shape of the central hole 2 and the permeable hole 4 when the gaseous fluid contains impurities, and to benefit...

Embodiment 3

[0029] This embodiment is further limited on the basis of any one of the technical solutions disclosed in any one of the above embodiments, such as figure 1 As shown, in order to facilitate the cooperation of the positioning hole 8 and the positioning pin 6 during the installation of the orifice plate body 1, the free end of the positioning pin 6 is also provided with a tapered guide tip. The reference point is a structural form for realizing the accurate positioning of the orifice plate body 1 and the connecting flange 7 , and there are two positioning pins 6 and two positioning holes 7 , and they are arranged in groups one by one. Wherein, setting one by one in groups means that one positioning pin 6 and one positioning hole 8 form one positioning point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com