Environment self-adaptive blade and control method thereof

An adaptive blade technology, which is applied in the control of wind turbines, wind turbines consistent with the wind direction, wind power generation, etc., can solve the problem that a single type of blade cannot meet the needs of various wind speed areas at the same time, so as to facilitate ice breaking and guarantee normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

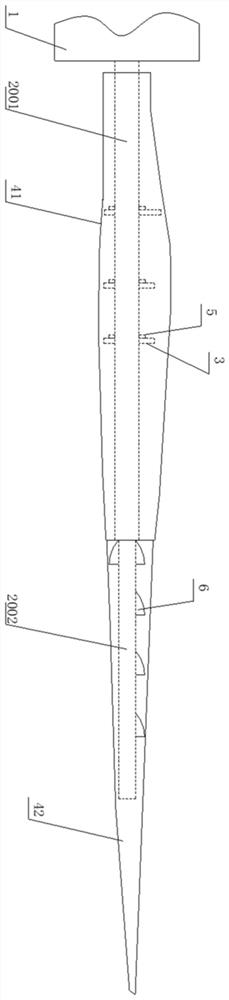

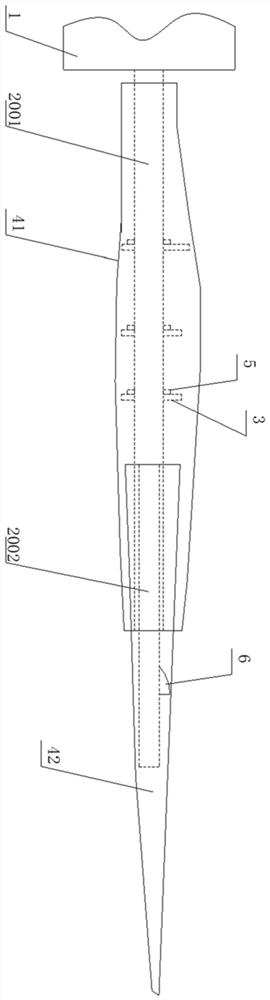

[0040] see figure 1 with figure 2 As shown, the present invention provides an environment-adaptive blade, including: a blade fixed end 41 , a blade movable end 42 , a main shaft fixed end 2001 and a main shaft movable end 2002 .

[0041] One end of the spindle fixed end 2001 is connected to the hub 1, and the other end is slidingly connected to the spindle movable end 2002; the interior of the spindle fixed end 2001 is hollow; the diameter of the spindle fixed end 2001 is larger than the diameter of the spindle movable end 2002; a section of the spindle movable end 2002 is accommodated in the spindle In the fixed end 2001 , the other end is fixedly connected with the movable blade end 42 .

[0042] The outer periphery of the main shaft fixed end 2001 is fixed with a blade fixed end 41 .

[0043] The blade fixed end 41 is provided with an accommodating cavity, which can accommodate part of the blade movable end 42 when the telescopic drive mechanism drives the main shaft mov...

Embodiment 2

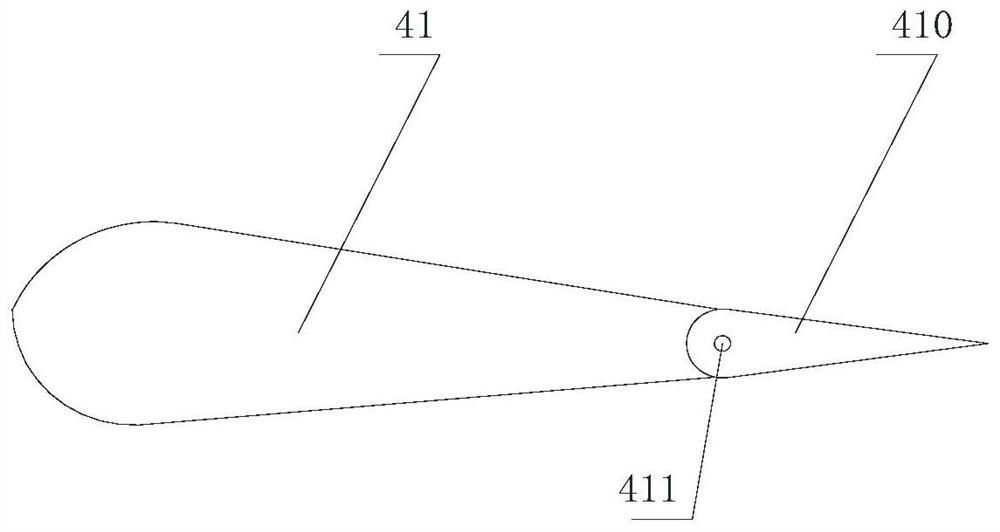

[0048] see image 3 with Figure 4 As shown, on the basis of Embodiment 1, an environment-adaptive blade of this embodiment is provided with a wing plate 410 on the edge of the fixed end 41 of the blade; the wing plate 410 is installed on the edge of the fixed end 41 of the blade through a rotating shaft, The rotation of the plate 410 can change the cross-sectional shape of the fixed end 41 of the blade, thereby adapting to different wind conditions.

Embodiment 3

[0050] see Figure 5 As shown, the present invention provides an environment-adaptive blade control method, which can independently determine the blade length and blade shape according to the wind energy quality and wind load at the point where the fan is located, specifically including the following steps:

[0051] S1. The airfoil central control system receives the environmental parameters tested by the environmental perception system in real time: wind speed and ice coverage;

[0052] S2. The blade shape central control system judges the working condition of the blade according to the collected environmental parameters; specifically, it includes: 1), the wind speed exceeding the set first threshold is the limit wind speed condition; 2), the ice thickness exceeding the set ice threshold is serious icing conditions; 3) the rest are non-limit conditions;

[0053] S3. For extreme wind speed conditions, the blade central control system starts the automatic risk avoidance mode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com