A kind of iron-based superconducting tape and its preparation method

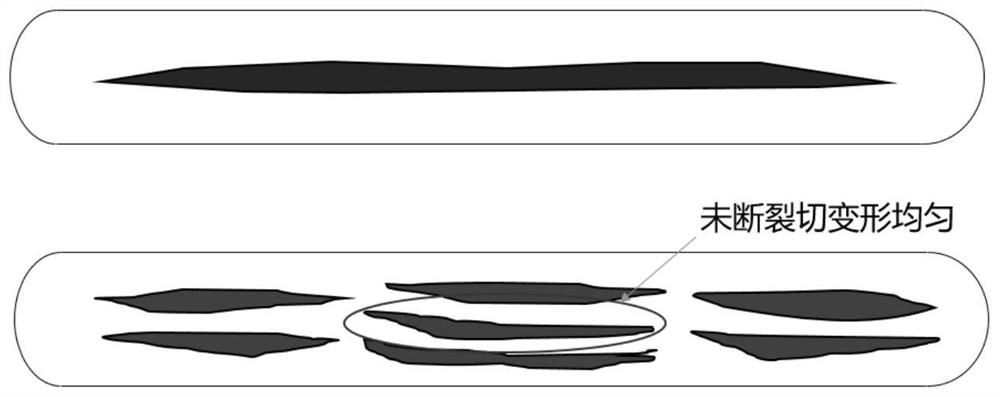

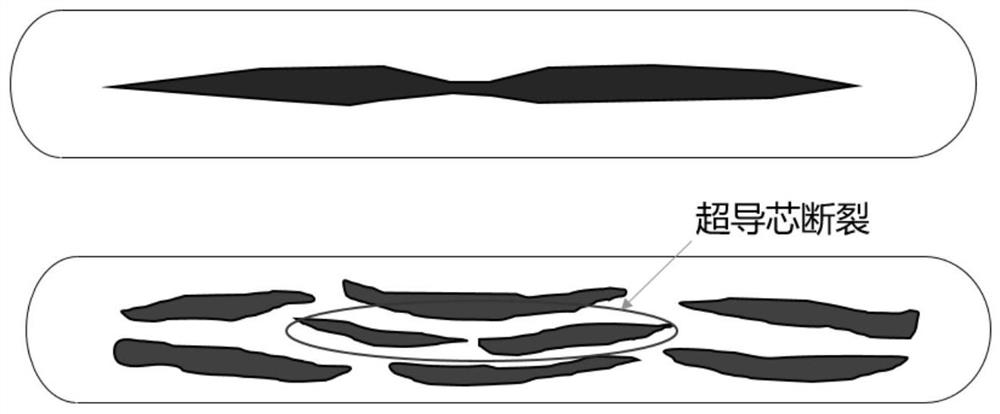

An iron-based superconductor and iron-based superconductor technology, which is applied in the usage of superconductor elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of easy fracture of superconducting cores, changes in thickness and width of superconducting cores Inhomogeneity, large amount of compression deformation, etc., to achieve the effect of optimizing critical current density, improving superconducting performance, and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a single-core iron-based superconducting tape and a preparation method thereof. The preparation method includes the following steps,

[0035] Under an inert atmosphere, the simple substances of iron, potassium, barium and arsenic were mixed and ball-milled and then put into a niobium tube, and calcined for 35 hours at 900°C and 10Mpa to obtain an iron-based superconducting precursor powder (Ba 1-x K x Fe 2 As 2 ), then put the iron-based superconducting precursor powder into the silver tube, seal the two ends with a softer metal, swage, and draw the silver tube filled with the superconducting precursor powder circularly until the diameter of the iron-based superconducting wire is 2.1mm, and then use the square mold in Table 1 to draw the iron-based superconducting wire in a square shape until a square strip with a side length of 1.45mm and a rounded corner of 0.2mm is formed, and then roll it into a side length of 4mm and 0.3mm thick strips, ...

Embodiment 2

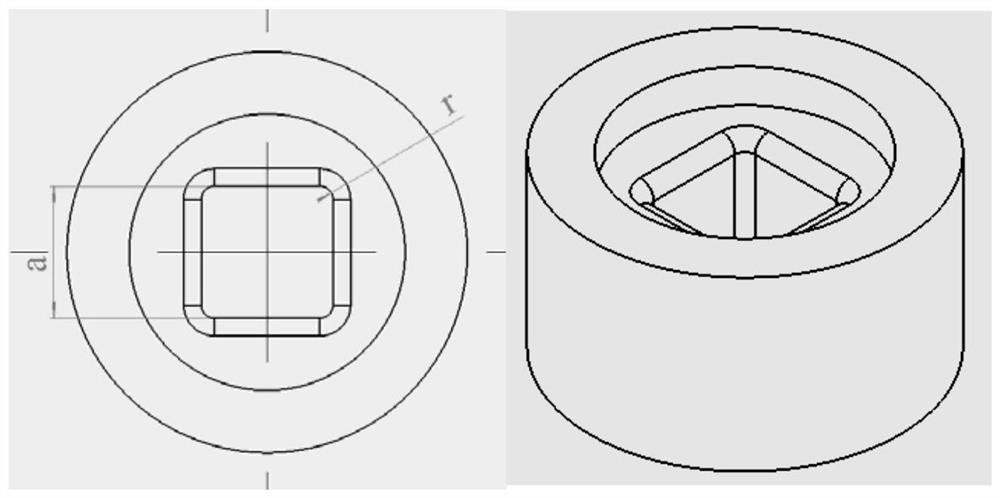

[0040] This embodiment provides a multi-core iron-based superconducting tape and a preparation method thereof. The preparation method includes the following steps,

[0041]Under an inert atmosphere, the simple substances of iron, potassium, barium and arsenic were mixed and ball-milled, put into a niobium tube, and calcined at 650 °C and 50 MPa for 10 h to obtain an iron-based superconducting precursor powder (Ba 1-x K x Fe 2 As 2 ), then put the iron-based superconducting precursor powder into the silver tube, seal the two ends with a softer metal, swage, and draw the silver tube filled with the superconducting precursor powder circularly until the diameter of the iron-based superconducting wire is 1.96mm, and then cut the round wire strip into 7 sections of the same length, and wipe it clean to obtain 7 superconducting cores, and then put them into a copper-silver alloy metal tube with an inner diameter of 6mm and an outer diameter of 8mm, Obtain composite wire;

[0042]...

Embodiment 3

[0044] This embodiment provides a single-core iron-based superconducting tape and a preparation method thereof. The preparation method includes the following steps,

[0045] Under an inert atmosphere, the simple substances of iron, sodium and arsenic were mixed and ball-milled and put into a niobium metal tube, and calcined for 35 hours at 900°C and 10Mpa to obtain iron-based superconducting precursor powder (NaFeAs), and then the iron-based superconducting precursor Put the powder into the silver tube, seal both ends with a softer metal, swage, and draw the silver tube filled with superconducting precursor powder circularly until the diameter of the iron-based superconducting wire is 1.95mm, and then use a square mold to shape the iron tube. The base superconducting wire is drawn in a square until a square strip with a side length of 1.55 mm and a rounded corner of 0.3 mm is formed, and then rolled into a strip with a side length of 3.8 mm and a thickness of 0.3 mm, and then r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com