Direct drive turntable thin-walled brake sleeve and braking method

A turntable and thin-walled technology, applied in the field of direct-drive turntables, can solve problems such as brake failure of thin-walled sleeves, elastic deformation of thin-walled sleeves, waste of energy, etc., to increase deformation, improve reliability, and avoid strength loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

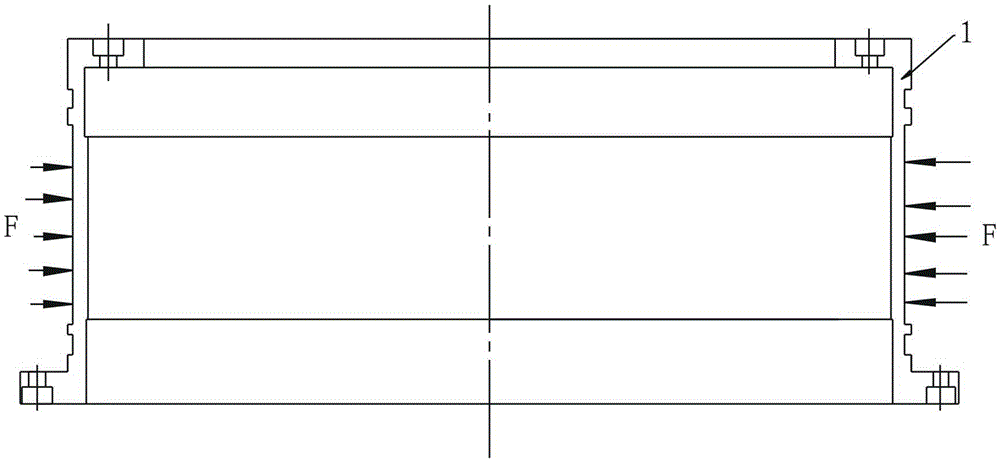

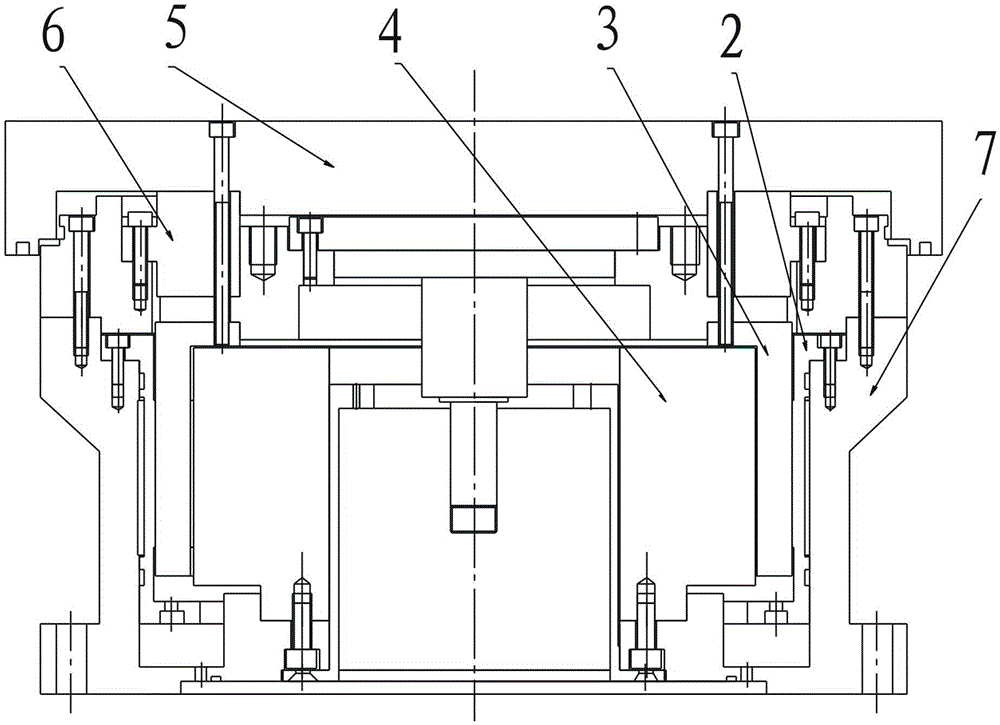

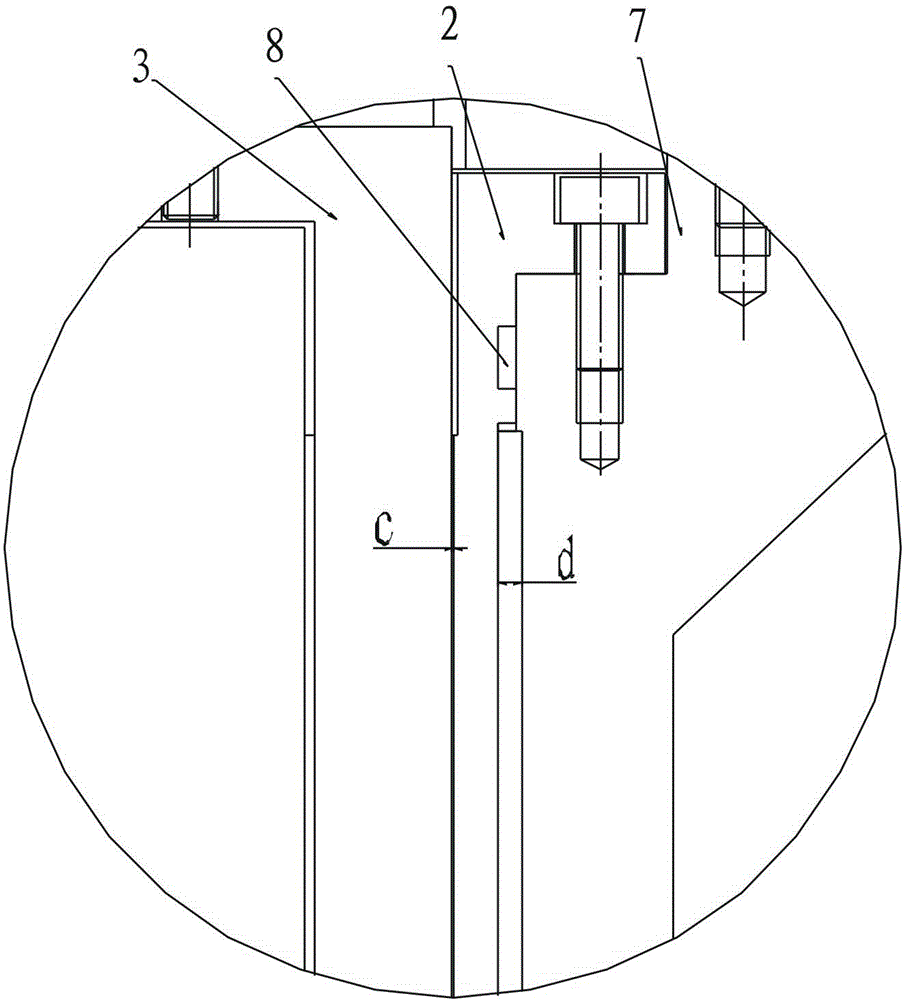

[0031] Such as Figure 2-4 As shown, the thin-walled brake sleeve 2 of the direct drive turntable implemented according to the present invention is arranged between the motor rotor of the direct drive turntable and the housing 7; the table 5 of the direct drive turntable is driven by the motor through the turntable bearing 6; the motor rotor It is the servo motor rotor assembly 3, and the inside of the rotor is the servo motor stator assembly 4; the main body of the thin-walled brake sleeve 2 is an annular cylinder, and the upper and lower end faces of the annular cylinder protrude in opposite directions to form an outer fitting with the shoulder of the housing 7. The extending edge, the extending edge at the upper end surface and the lower end surface are all fixed on the housing 7; the cross section of the annular cylinder is an elliptical ring, along the height direction of the annular cylinder, between the outer edge of the elliptical ring and the inner wall of the housing T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com