Detection fixture device used for detecting sealing of welding part

A technology for detecting parts and airtightness, which is applied in the field of inspection tools for detecting the airtightness of welded parts, to achieve the effects of fast measurement process, lower false detection rate, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

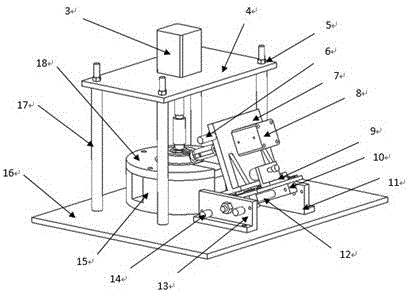

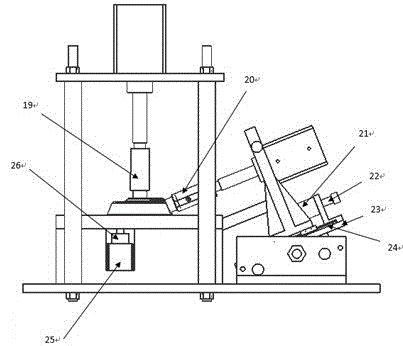

[0014] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

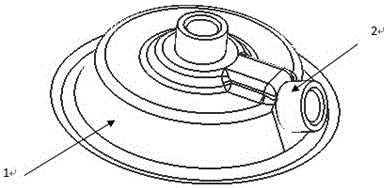

[0015] Such as Figure 1-Figure 5 As shown, the technical solution of the present invention relates to a device for detecting the sealing of welding parts, including a detection part (1), a welding part (2), a cylinder (3), a cylinder mounting plate (4), a nut (5 ), rotary handle (6), rotary cylinder mounting plate (7), cylinder two (8), baffle plate (9), rotary block (10), right bracket (11), rotary shaft (12), left bracket (13 ), latch (14), fixed platform (15), lower platform plate (16), column (17), part placement platform (18), connecting column (19), connecting column (20), spring (21), limit Bit screw (22), rotating plate (23), linear slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com