Pieces tensile testing machine

A tension test and tuft technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of large numerical deviation, inaccurate results, and inconsistent pulling speed of tufts. Achieve the effect of improving accuracy and reducing bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

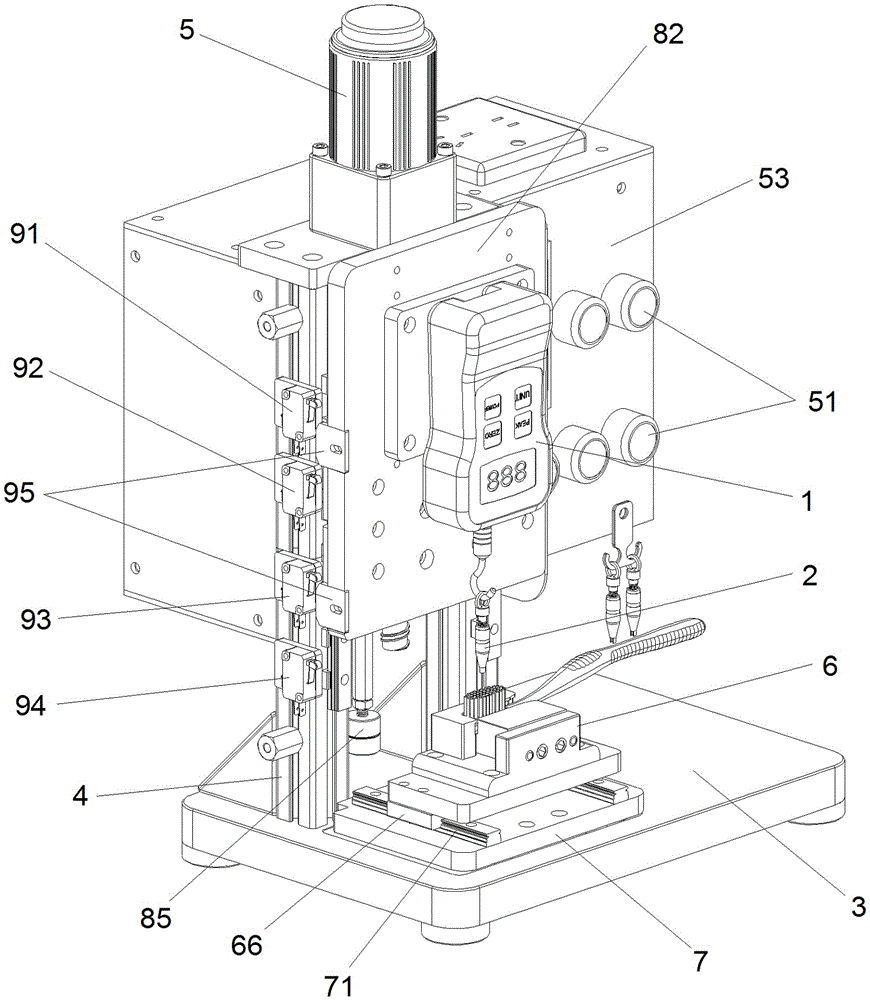

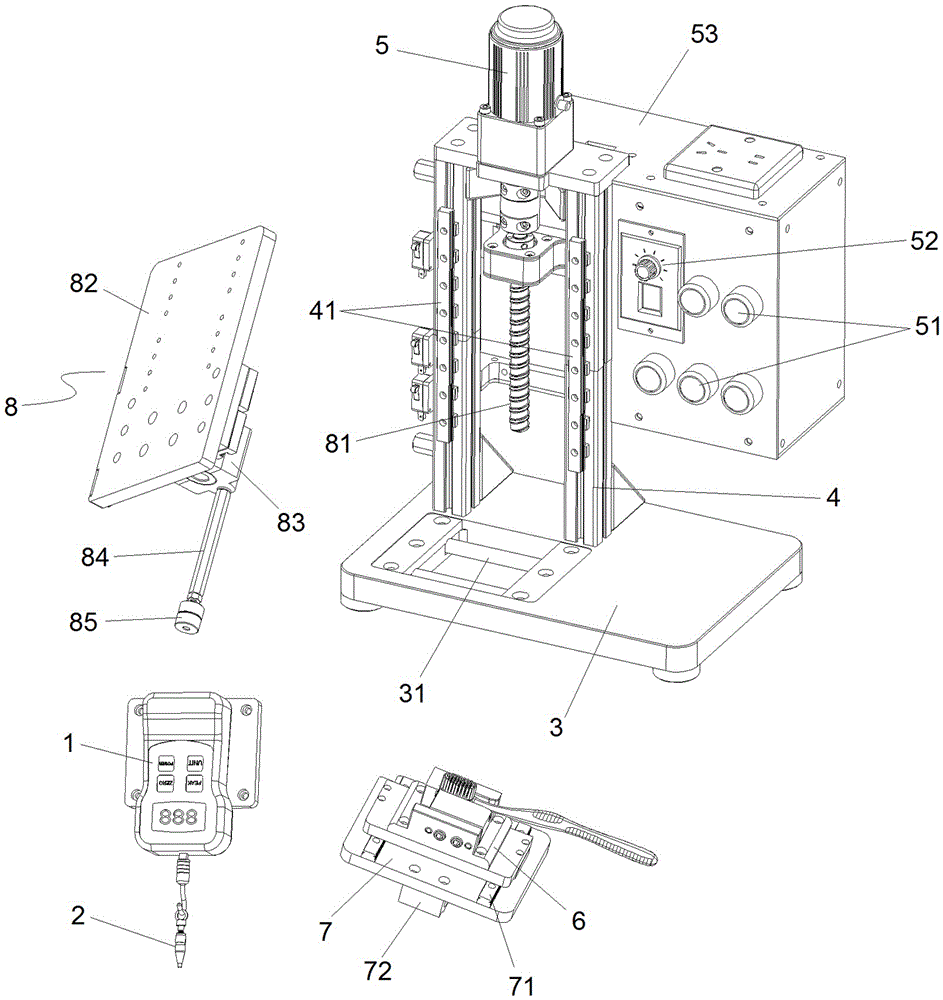

[0027] Such as figure 1 with figure 2 As shown, the tuft tensile testing machine of the present invention is used to test the tensile strength value of the tuft 30 planted on the brush head 20, which includes: a tensioner 1, a tuft clamp 2, a base plate 3, and is fixed on the base plate 3 Frame 4, motor 5 and start button 51 thereof, brush head clamp 6 for positioning the brush head, clamp slide plate 7 and moving mechanism 8. The above components will be described in detail below.

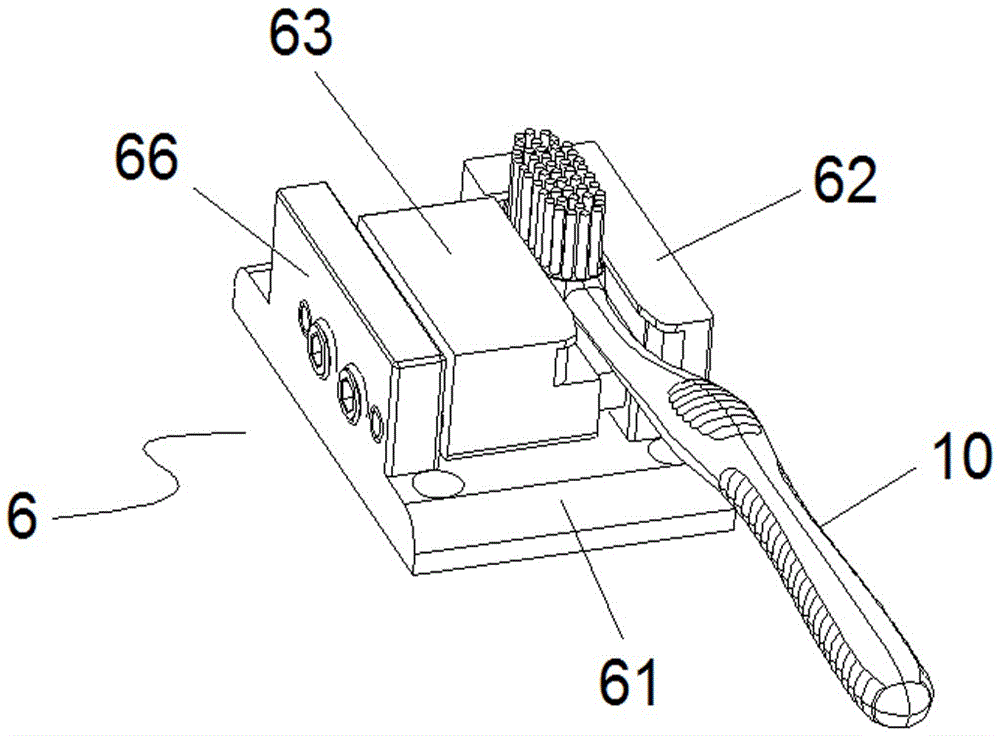

[0028] Such as image 3 , Figure 4 with Figure 5 As shown, the brush head holder 6 is used to securely hold the brush head component to be tested, such as the toothbrush 10, so as to carry out the tensile test of the hair bundle. The brush head clamp 6 includes: a clamp base 61, a fixed clamp block 62 fixed on the clamp base 61, a sliding clamp block 63 slidably connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap