Manual assembly visual detection error prevention method and system

A manual assembly and visual inspection technology, applied in image data processing, instruments, calculations, etc., can solve the problems of low discrimination between operators and fine operation actions, and cannot cover complex assembly operations, so as to improve the one-time completion rate and save The time for self-inspection and review of process manuals, and the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

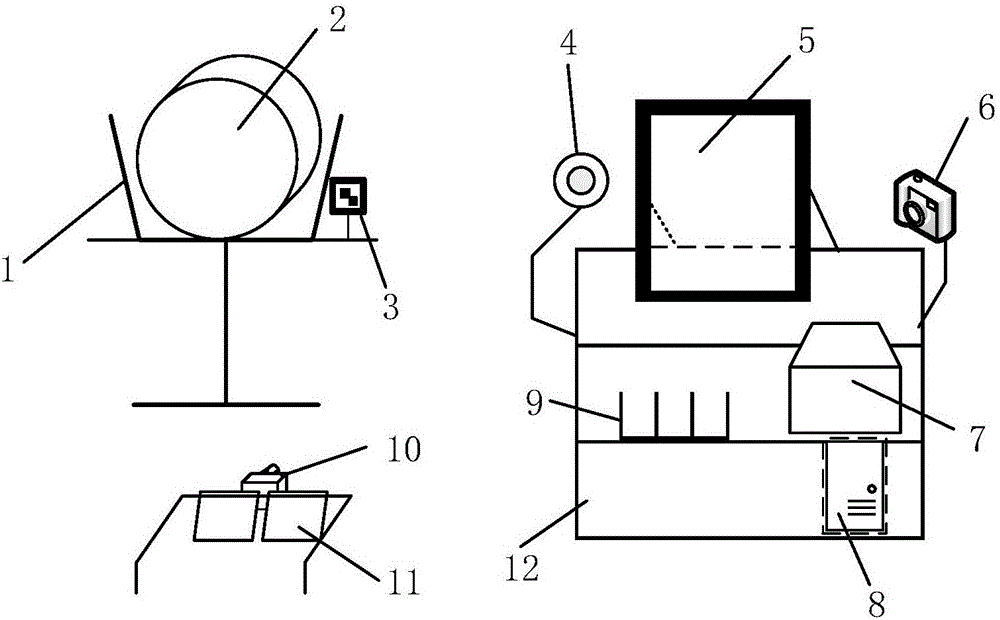

[0041] Such as figure 1 As shown, the visual error prevention system for tooling and assembly in this embodiment includes: a head-mounted video capture device 10, a fixed video capture device 6, lighting equipment 4, a retrieving box 9, a background plate 7, a material rack 12, and a head-mounted optical aid The display device 11, the interactive display device 5 and the control module 8, wherein: the head-mounted video acquisition device 10 collects the first-view image of the manual assembly and transmits it to the control module 8; the fixed video acquisition device 6 collects the parts after the assembler picks up the parts The image is transmitted to the control module 8; the head-mounted optical auxiliary display device 11 outputs and displays assembly process guidance information to the assembly operator, and is respectively connected with the head-mounted video acquisition device 10 and the control module 8; the interactive display device 5 and the control module 8 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com