Multi-robot teaching and real training platform

A training platform and multi-robot technology, applied in teaching models, instruments, simulators, etc., can solve the problems of large size, lack of Delta parallel robots and SCARA robots, and large inertia, and achieve high safety, rich and friendly human-machine Interface, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

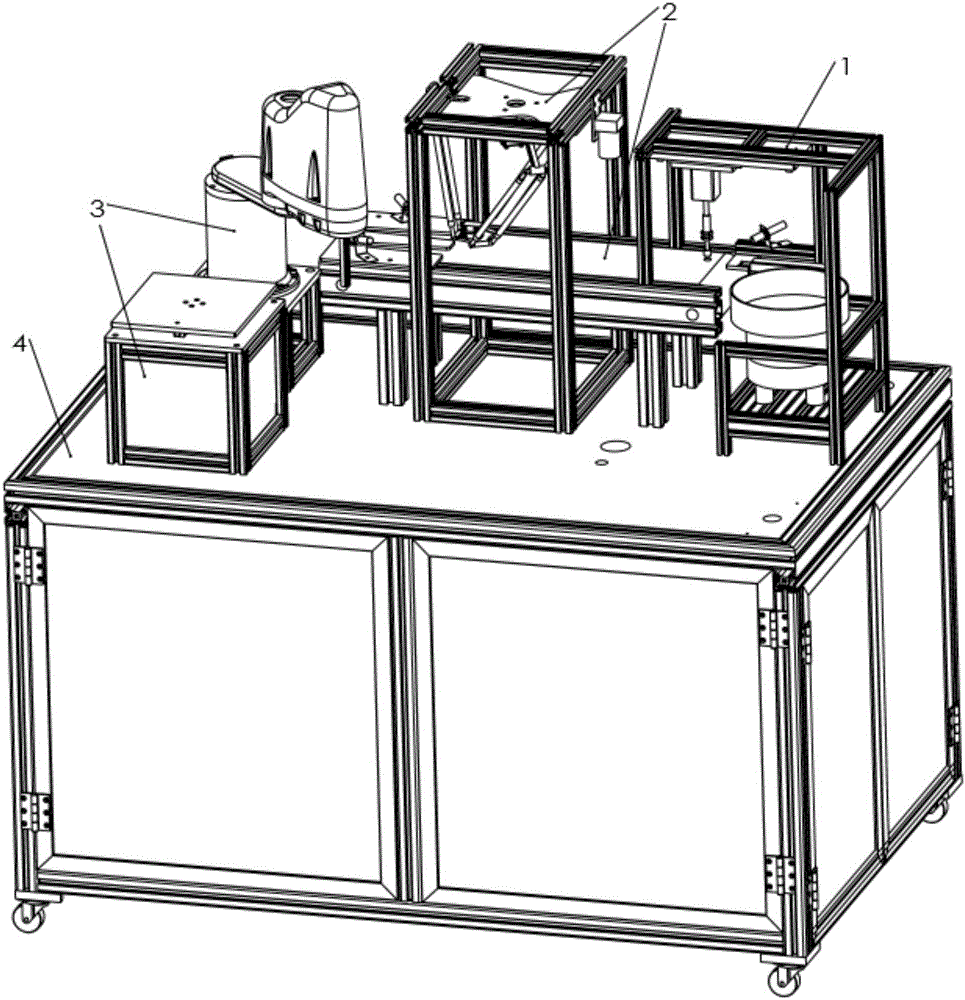

[0030] Such as figure 1 As shown, the present invention relates to a multi-robot teaching and training platform, including a feeding unit 1, a sorting unit 2, a handling unit 3, a logic control unit and a training table 4, and the logic control unit is installed on the training table 4 Inside, all the other units are installed on the training table 4 in turn to form an assembly line.

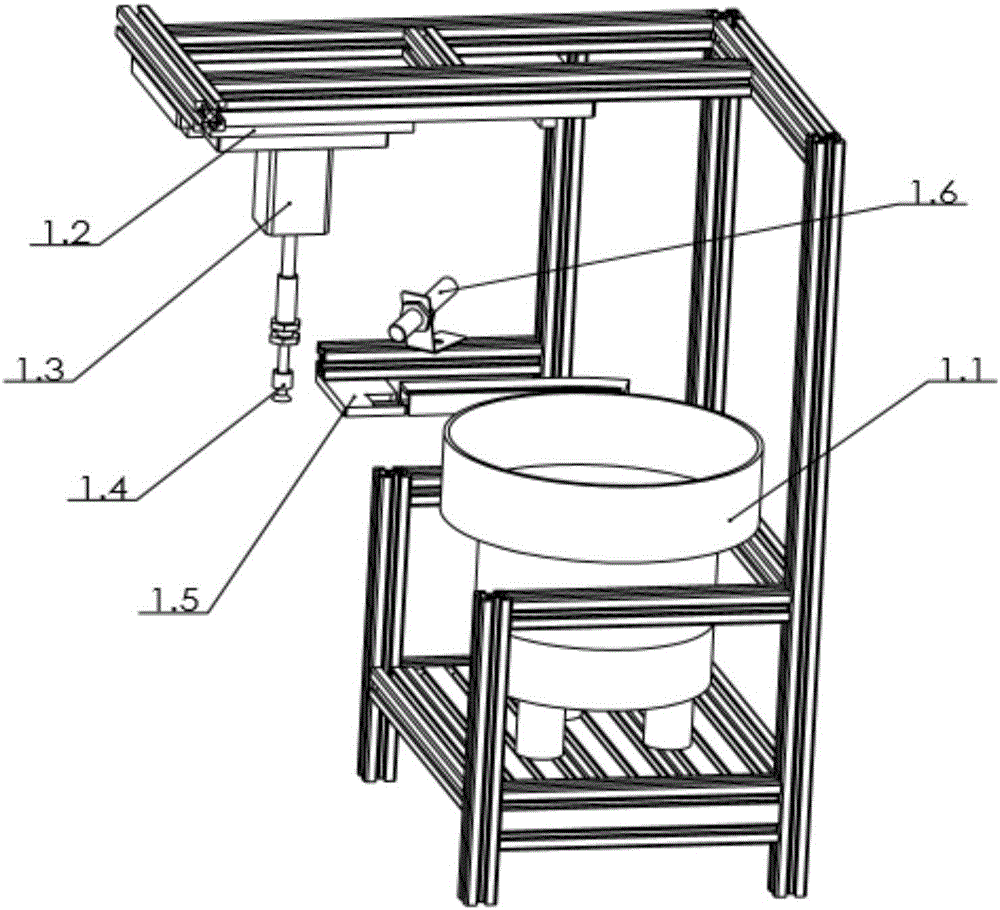

[0031] Such as figure 2 As shown, the feeding unit 1 is composed of a vibrating plate 1.1, a linear cylinder 1.2 in the front and rear directions, a linear cylinder 1.3 in the vertical direction, a first vacuum suction cup 1.4, a discharge positioning plate 1.5, and a photoelectric sensor 1.6 for feeding. The discharge positioning plate 1.5 is installed at the discharge port of the vibrating plate 1.1, the loading photoelectric sensor 1.6 is installed on the discharge positioning plate 1.5, and the front and rear direction linear cylinder 1.2 is installed above the discharge positioning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com