Detecting method and system for integrity of nuclear power station fuel element cladding

A fuel element and nuclear power plant technology, applied in the field of nuclear power plant instrumentation and control, can solve the problems of increasing the coolant or environmental gamma dose rate, unable to quantitatively monitor the damage rate of the fuel element cladding, affecting the reliability of the measurement method, etc., to achieve high feasibility and reliability. Sensitivity, the effect of avoiding false measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

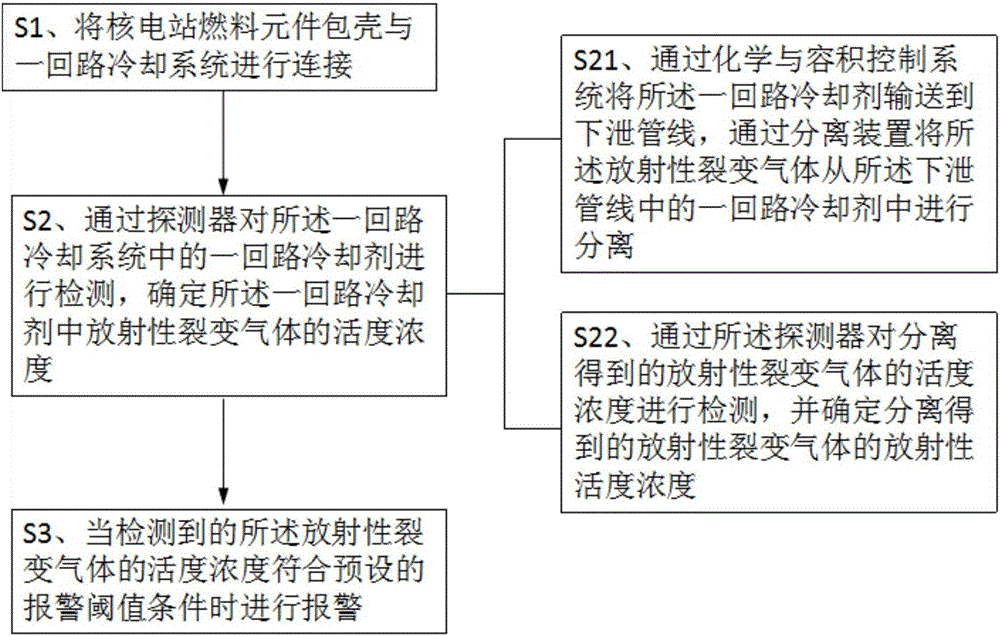

[0051] figure 1 The flow chart of the detection method for the cladding integrity of nuclear power plant fuel elements in the present invention is shown, which specifically includes the following steps:

[0052]S1. Connect the fuel element cladding of the nuclear power plant to the primary cooling system; if the fuel element cladding is damaged, the radioactive fission and decay products contained in the fuel element will enter the coolant of the primary cooling system;

[0053] S2. Detect the primary loop coolant in the primary loop cooling system through detectors to determine the activity concentration of the radioactive fission gas in the primary loop coolant; the inert gas is produced in the nuclear fission process of the nuclear fuel inside the reactor, and the fission In the process, nuclear energy, fission products and decay products are released, wherein the fission products and decay products contain inert gas, therefore, the radioactive fission gas in the above step...

Embodiment 2

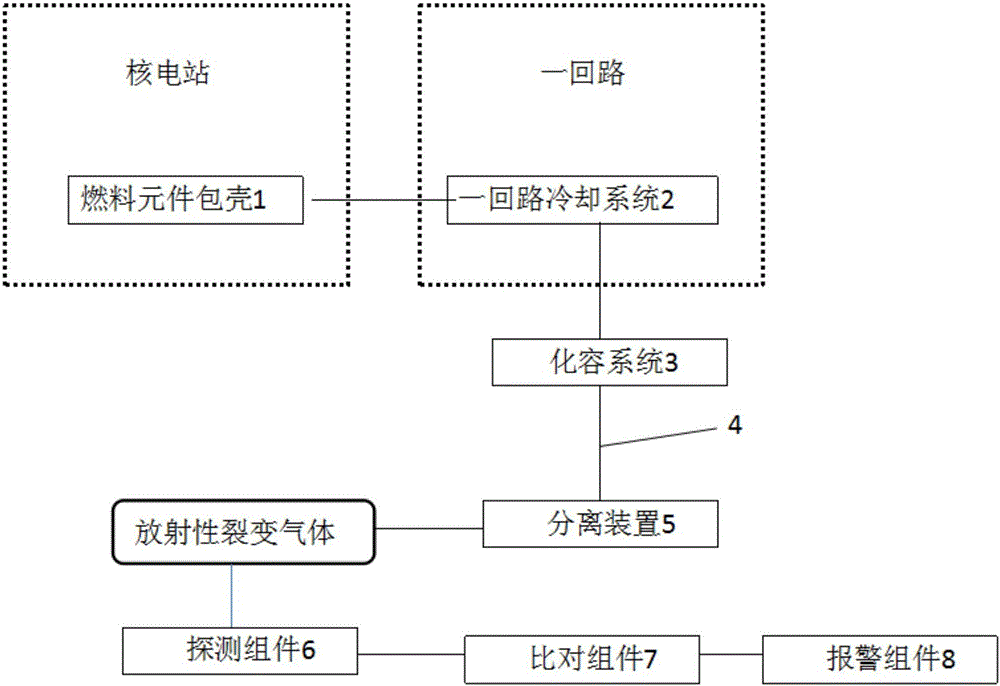

[0068] figure 1 A schematic diagram of the system structure of the detection method for the integrity of the nuclear power plant fuel element cladding in the present invention is shown, which specifically includes:

[0069] The detection assembly 6 is connected to the primary circuit cooling system 2 connected to the nuclear power plant fuel element cladding 1, and is used to detect and output the activity concentration of the radioactive fission gas contained in the primary circuit coolant of the primary circuit cooling system 2;

[0070] A comparison component 7, which is connected to the detection component 6, is used to receive the detected activity concentration output, and compare the detected activity concentration with the preset alarm threshold condition, if it meets alarm threshold condition, an alarm signal is generated and sent;

[0071] And an alarm component 8, which is connected to the comparison component 7, is used to receive the sent alarm signal, and give a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com