Open type micro channel plate assembly used for space environment

A technology of micro-channel plate and space environment, which is applied in the field of mechatronics, can solve the problems that the product cannot meet the requirements of processing and manufacturing, and the process is complicated, so as to achieve the effects of improving reliability, good processing technology, and strong insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

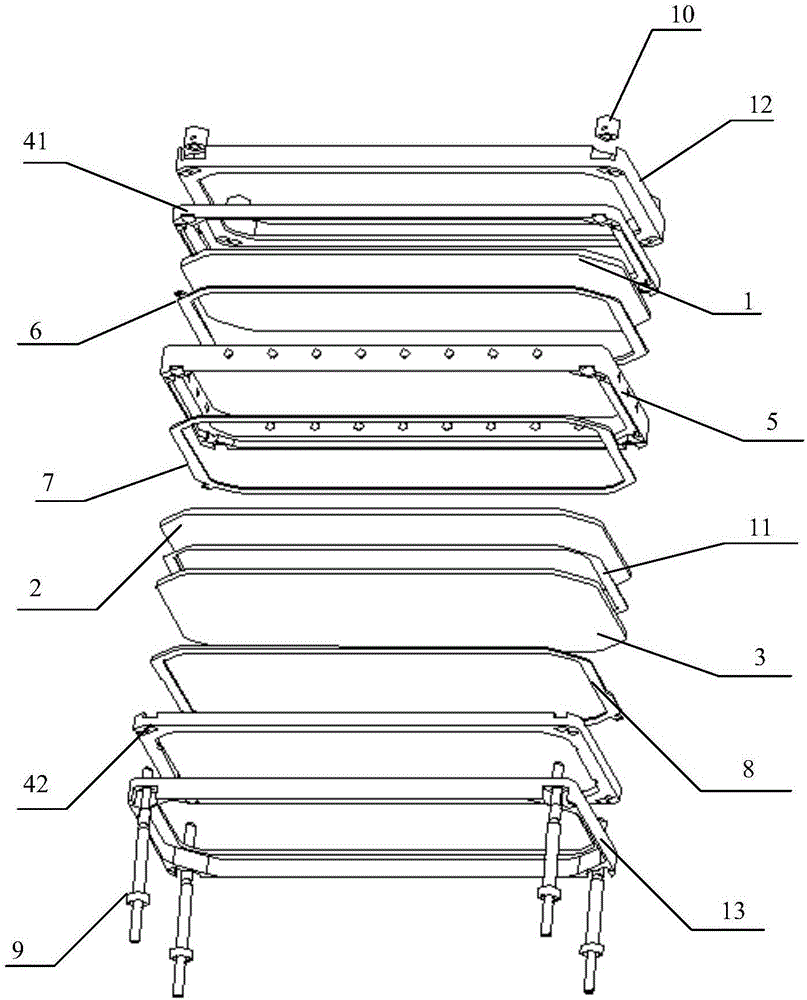

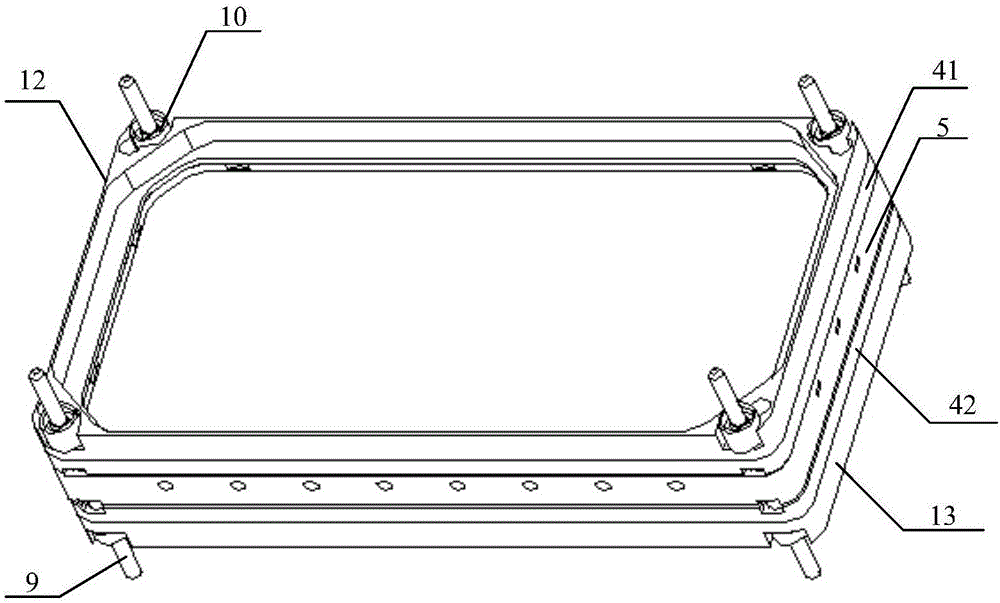

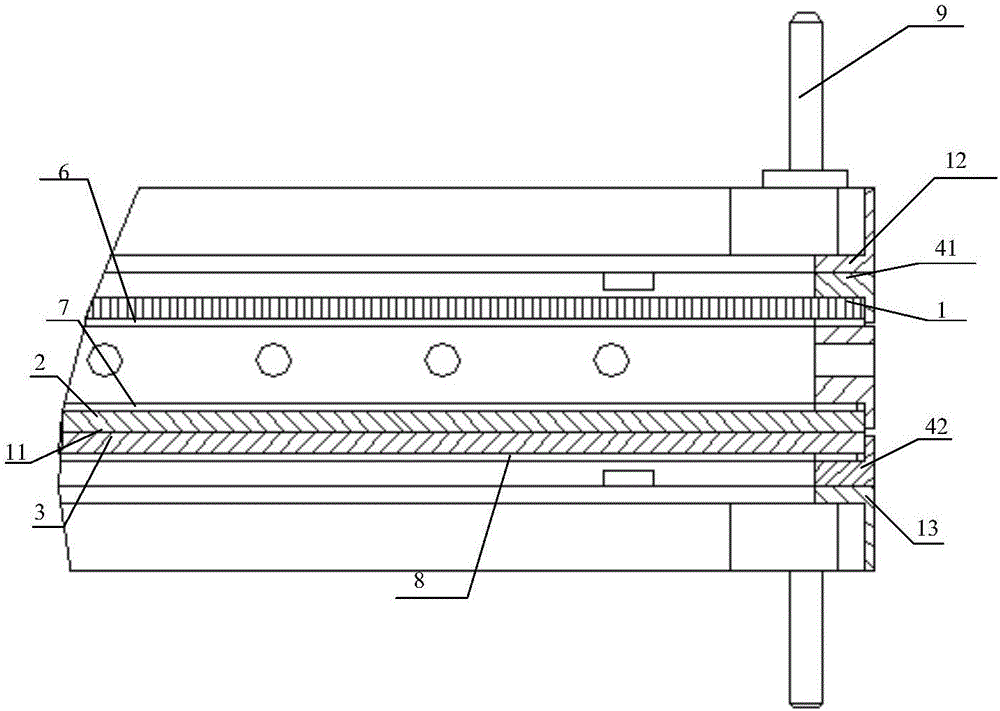

[0028] Such as figure 1 As shown, the microchannel plate assembly of the present invention includes an upper outer support frame 12, an upper support frame 41, an MPO (microporous optical device) plate 1, a first electrode 6, a middle support frame 5, and a second electrode 7 from top to bottom. , the first MCP board 2, the conductive foil 11, the second MCP board 3, the third electrode 8, the lower support frame 42 and the lower end outer support frame 13; the MPO board 1, the first MCP board 2 and the second MCP board 3 are all The rectangular structure with an aspect ratio of 2:1 can be easily spliced, and can be spliced into a rectangle or a square, suitable for an array structure.

[0029] The outer support frame 12 at the upper end, the upper support frame 41, the middle support frame 5, the lower support frame 42 and the outer support frame 13 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com