A positive electrode powder lithiation contact interface automatic renewal mechanism

A contact interface and automatic update technology, applied to the electrodes of primary batteries, delayed action cells, etc., can solve the problem that the update rate and update uniformity have a great influence on the lithiation effect, it is difficult to meet the powder interface update requirements, and the quality of positive electrode powder is affected. Consistency and other issues, to avoid too fast update degree, avoid continuous reduction, stable and reliable operation of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

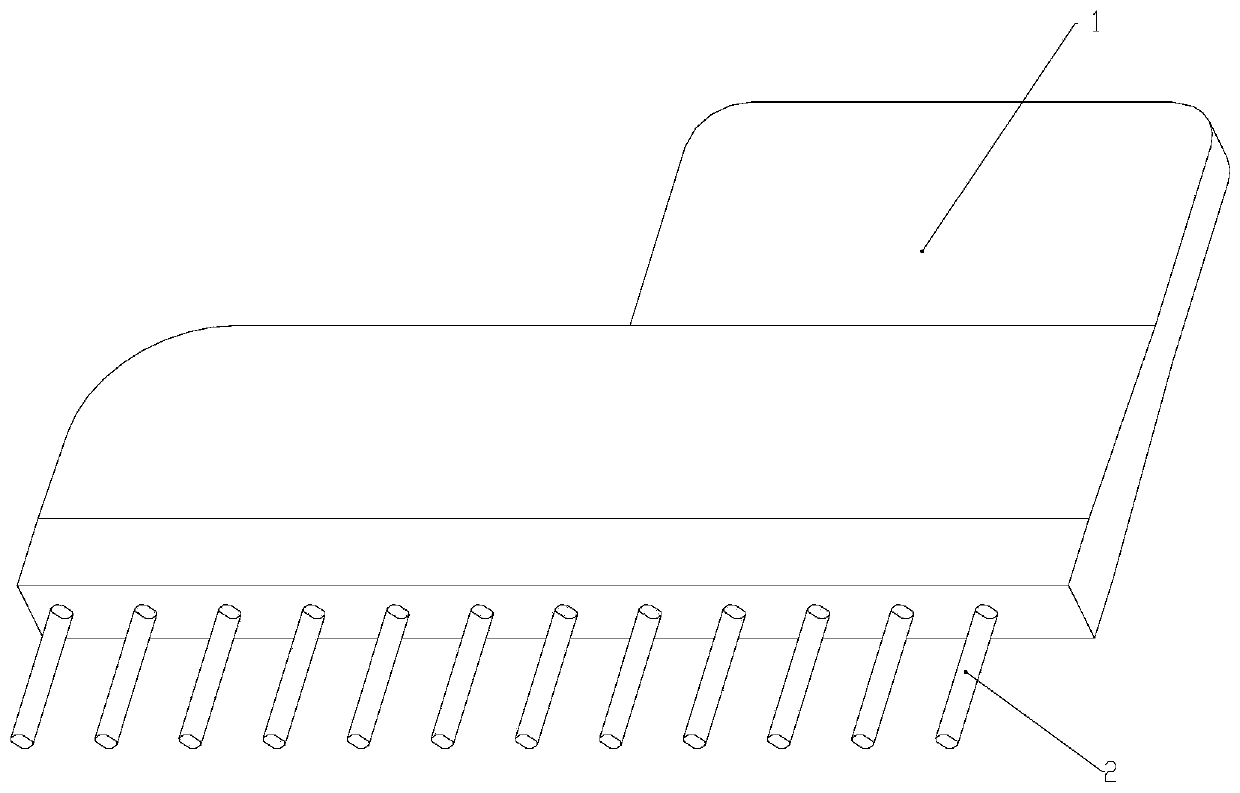

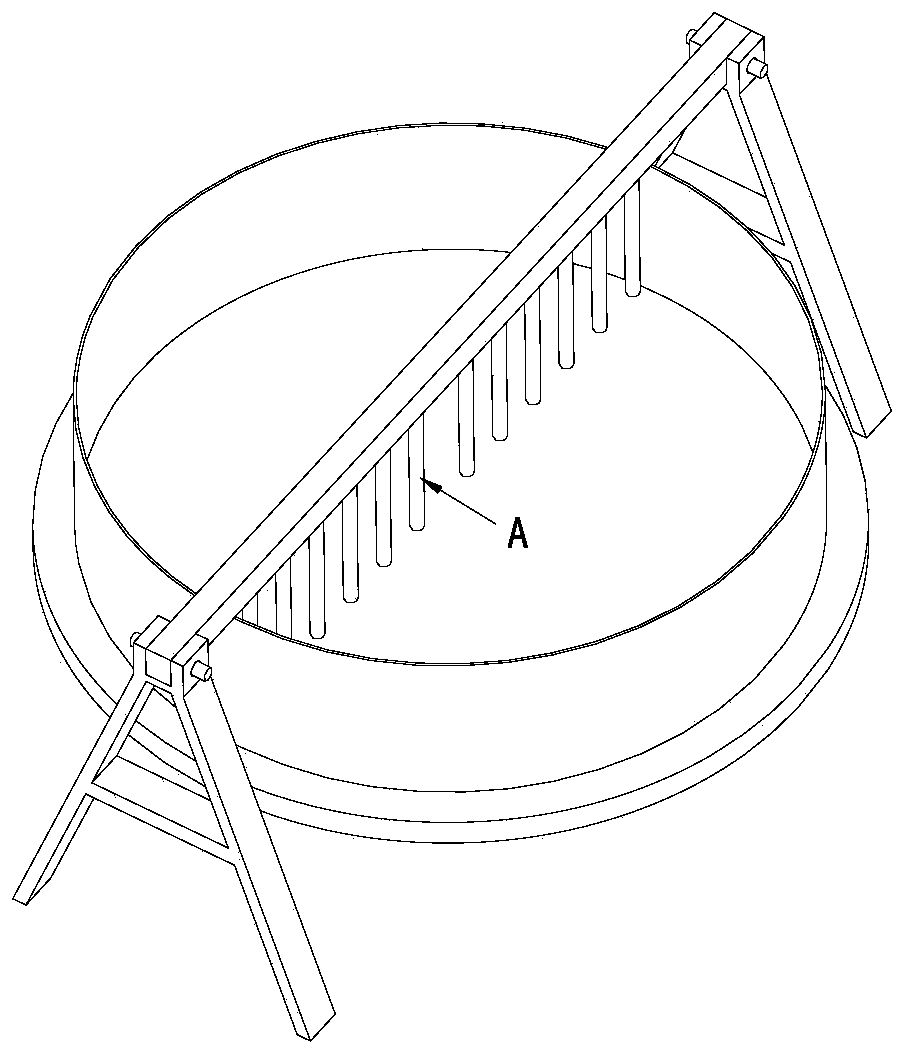

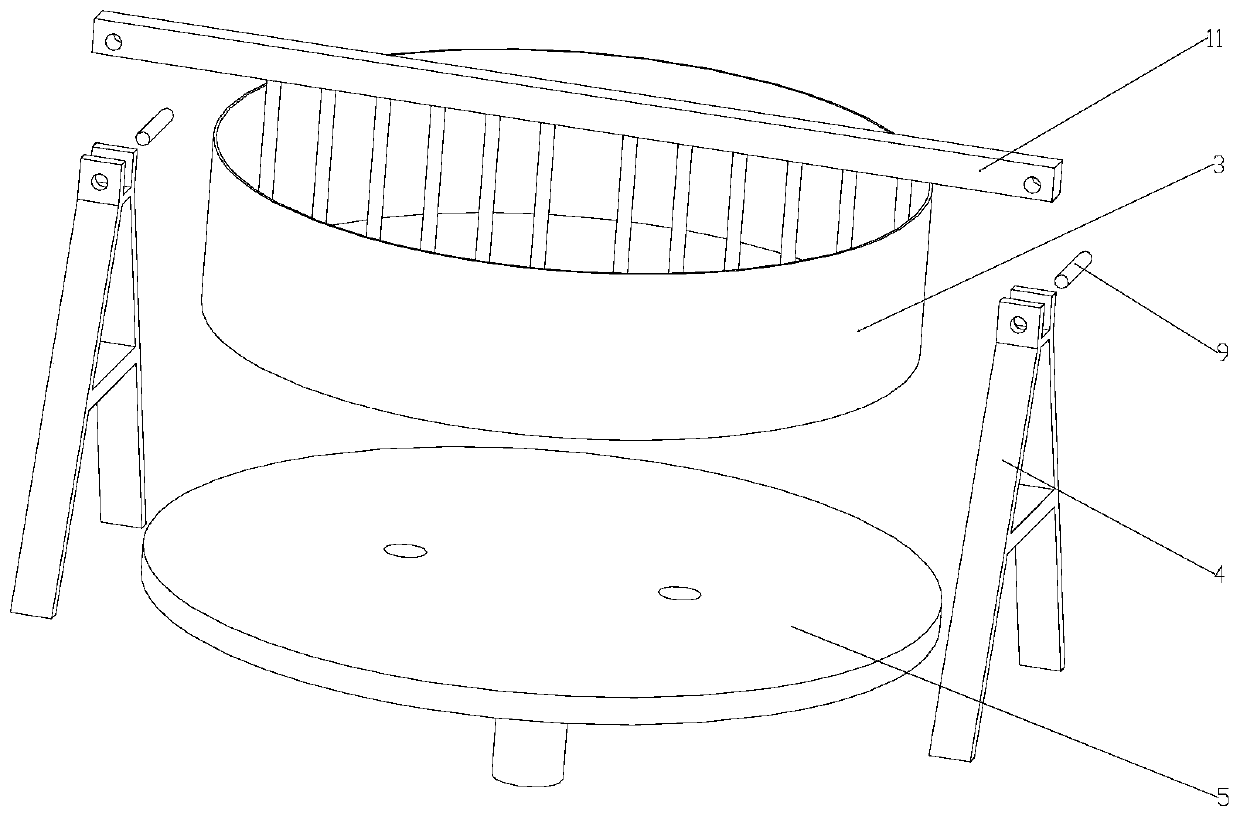

[0035] figure 2 It is a structural schematic diagram of the present invention, image 3 is the engineering assembly drawing of the present invention, Figure 4 yes figure 2 The partial section view in middle A enlarges the engineering assembly drawing. First, the lithiated beam 11 is assembled. Insert the spring 7 at the end of the mechanical lithiation tooth 8, and then insert the mechanical lithiation tooth 8 into the corresponding hole of the crossbeam 6, so that the threaded surface of the tail end of the mechanical lithiation tooth 8 exposes the crossbeam 6, and screw the upper limit nut 10 at the tail. After loosening, the limit nut 10 is positioned on the beam 6 . Then install all mechanical lithiated teeth 8 sequentially according to the above method.

[0036] Then put the positive electrode powder to be processed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com