Square lithium battery lamination machine and lamination technology

A lithium battery and stacking machine technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of large impact on the charging and discharging performance of the battery cell, inconsistent tension of the winding layer, wrinkles, etc., and achieve product consistency Good, good consistency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

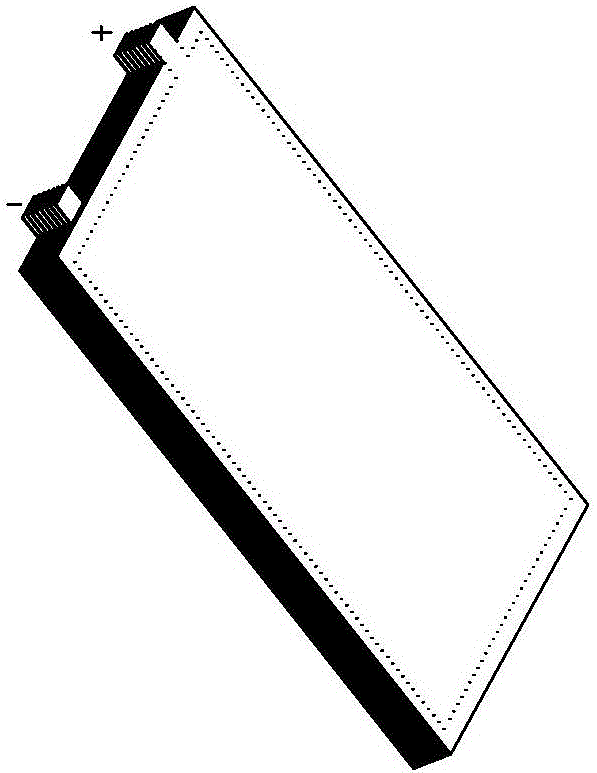

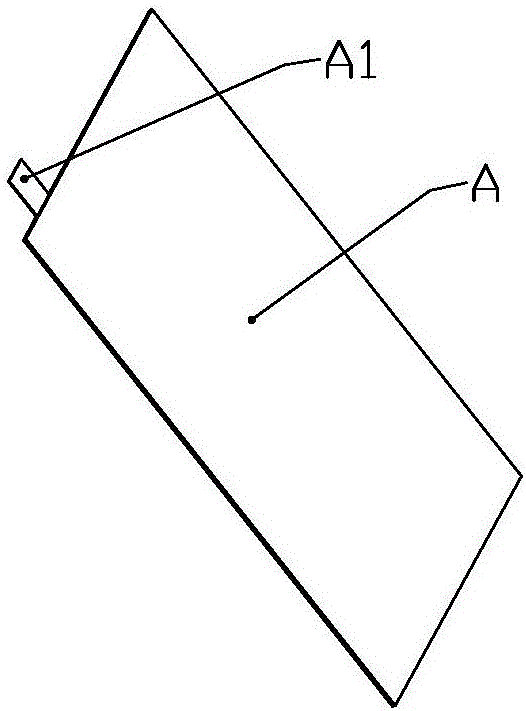

[0066] Due to the different production processes of various manufacturers, polymer lithium batteries currently on the market are divided into two different structures: winding type (represented by Sony and Toshiba) and laminated type (represented by TCL and ATL).

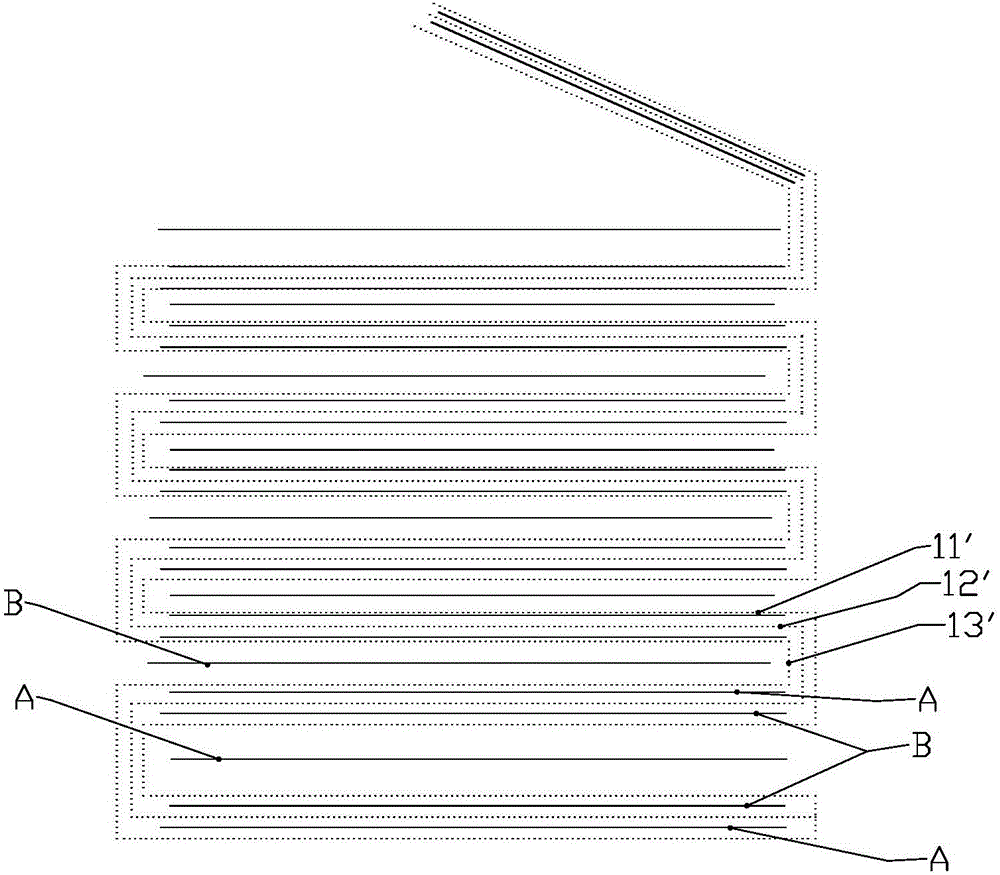

[0067] The existing stacking machine and stacking principle are discs layer by layer, that is, a continuous diaphragm is used, the diaphragm is bent in a Z shape using a stacking machine, and the positive and negative plates are implanted at intervals. Laminations are formed in the diaphragm interlayer, which is inefficient. Although the degree of automation can be improved, it is still difficult to meet high-efficiency production.

[0068] The usual design idea is to improve the feeding efficiency of the diaphragm, that is, to use continuous, high-speed continuous film feeding to increase production capacity.

[0069] However, the traditional method has defects. The problem is that when the film feeding speed reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com