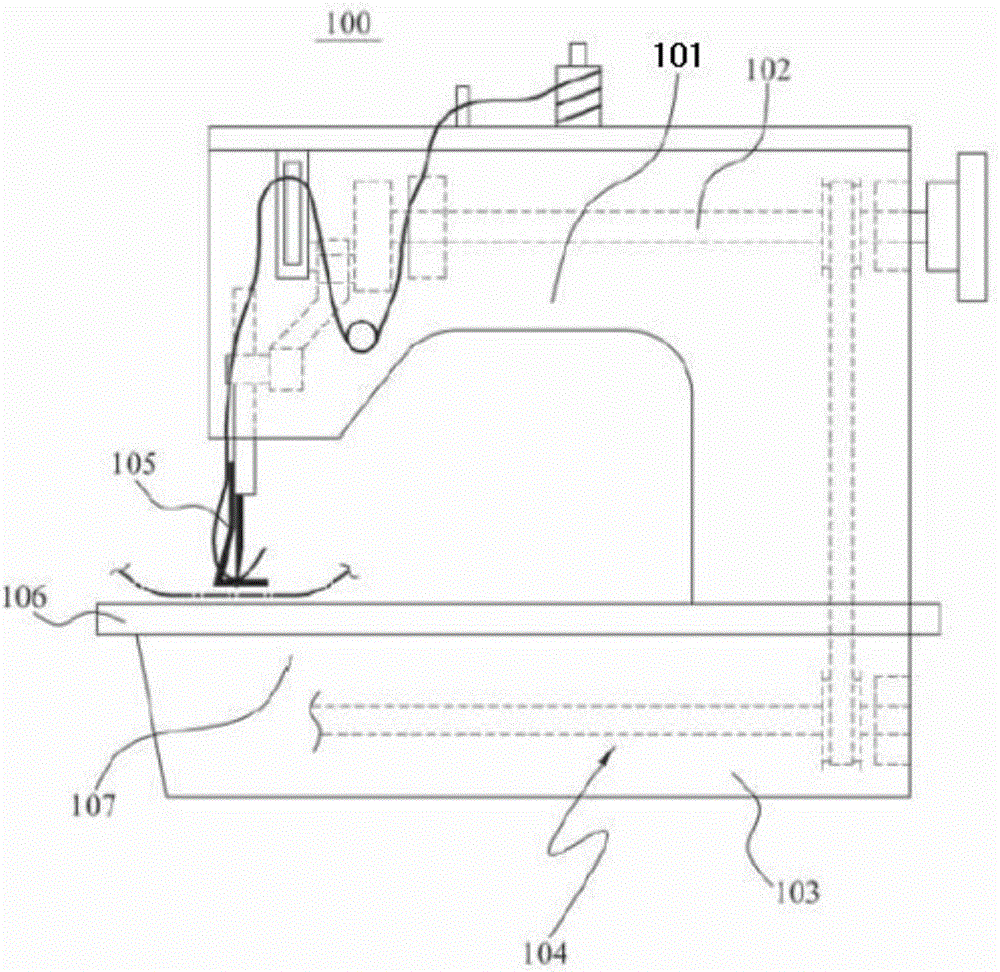

Lower shaft support device for sewing machine

A technology of shaft support and sewing machine, which is applied in the direction of control device for sewing machine, sewing machine components, sewing equipment, etc., can solve the problems of increasing the number of accessories, can not meet high precision, etc., to prevent driving noise and vibration, save cost and time, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

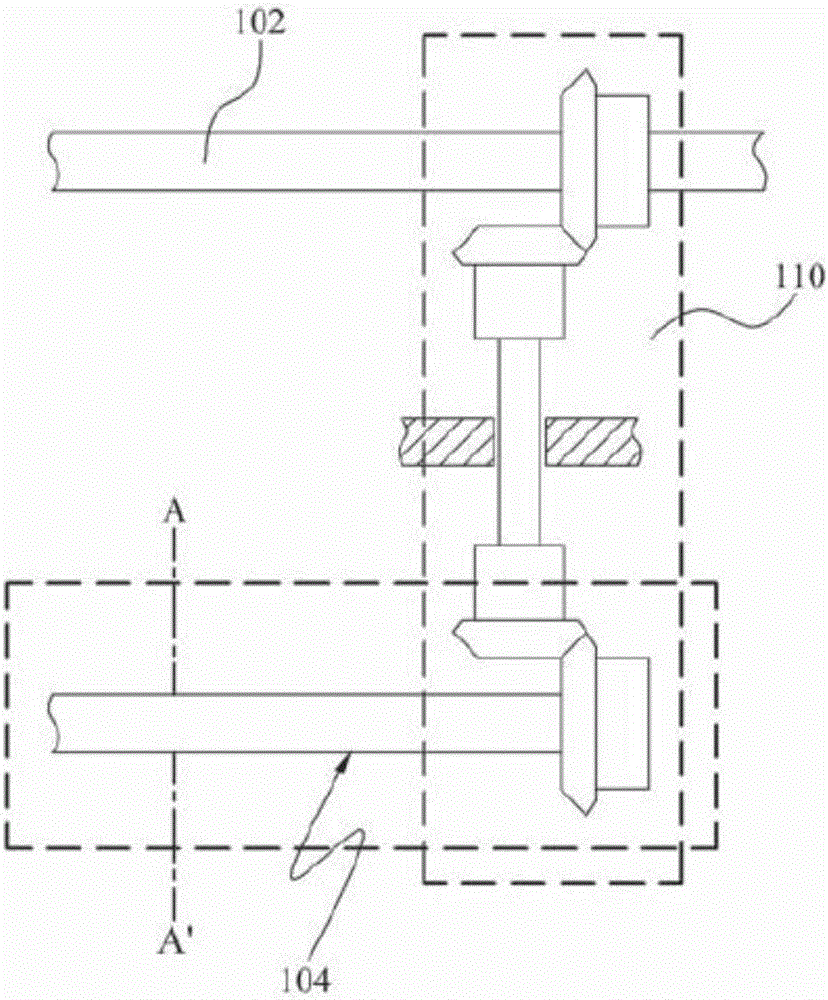

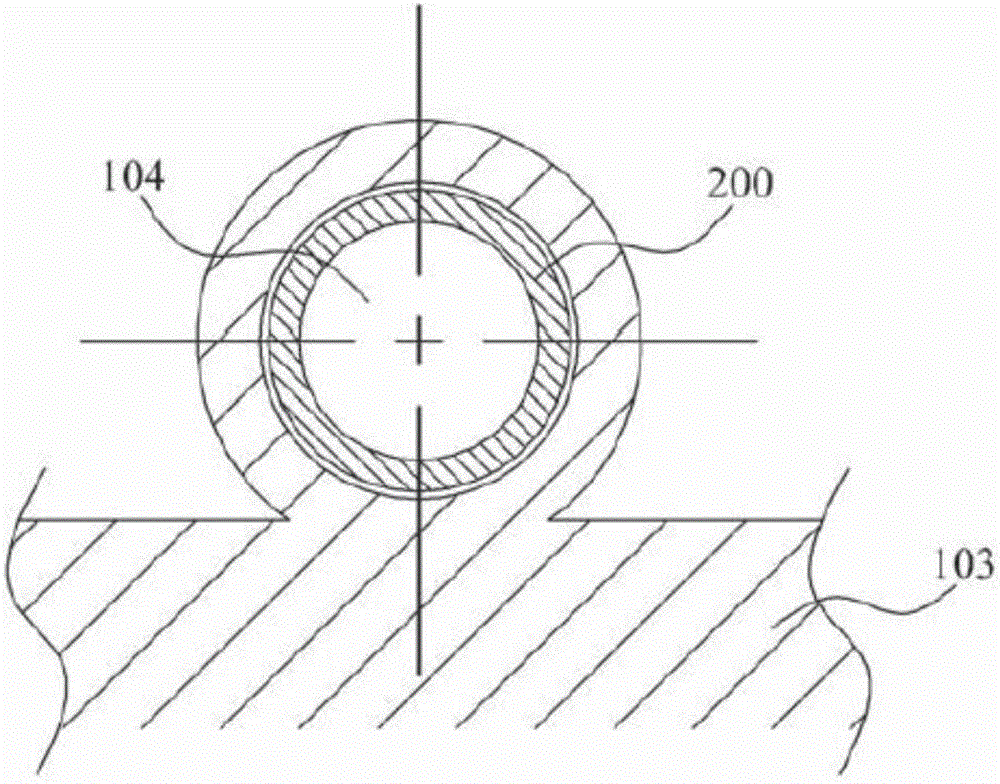

[0038] In the lower shaft supporting device of the sewing machine involved in the embodiment of the present invention, the lower shaft 104 is installed on the machine tool 103 so as to interact with the upper shaft installed on the angle arm of the sewing machine body, wherein no special bearing is used on the machine tool 103 of the sewing machine body Instead of metal bushings, the cast bushing 300 is mounted directly to support the lower shaft 104 .

[0039] Figure 4 It is a plan view of the sewing machine bed according to the embodiment of the present invention. Figure 5 yes Figure 4 left side view of the . Figure 6 yes Figure 4 right side view of . Figure 7 yes Figure 4 partial sectional view.

[0040] refer to Figure 4 to Figure 7 , the machine tool 103a has one or more casting bushes 300 for guiding and mounting the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com