Insulator water-washing device and robot

An insulator and water flushing technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of difficult manual operations, low labor intensity, and heavy workload, and achieve the realization of No dead angle flushing, thorough cleaning, fast cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

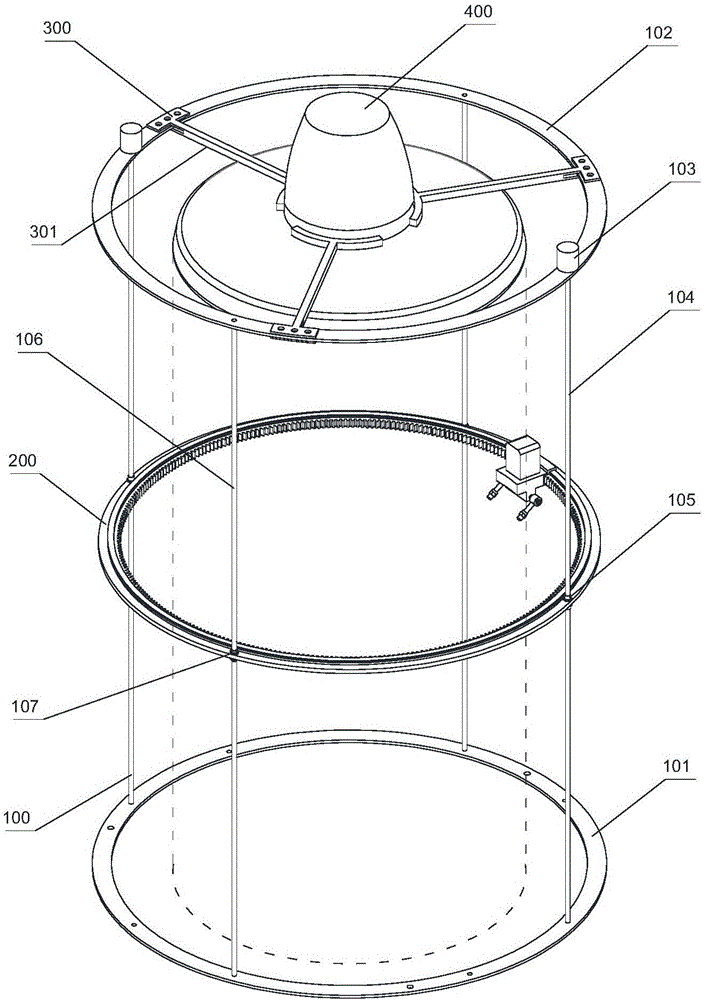

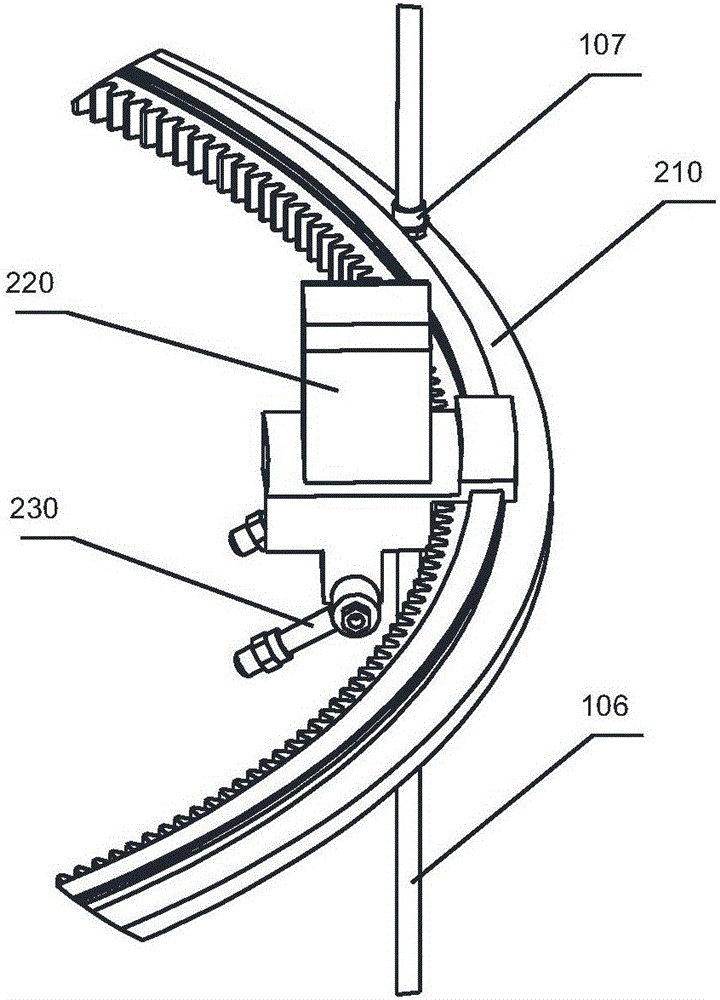

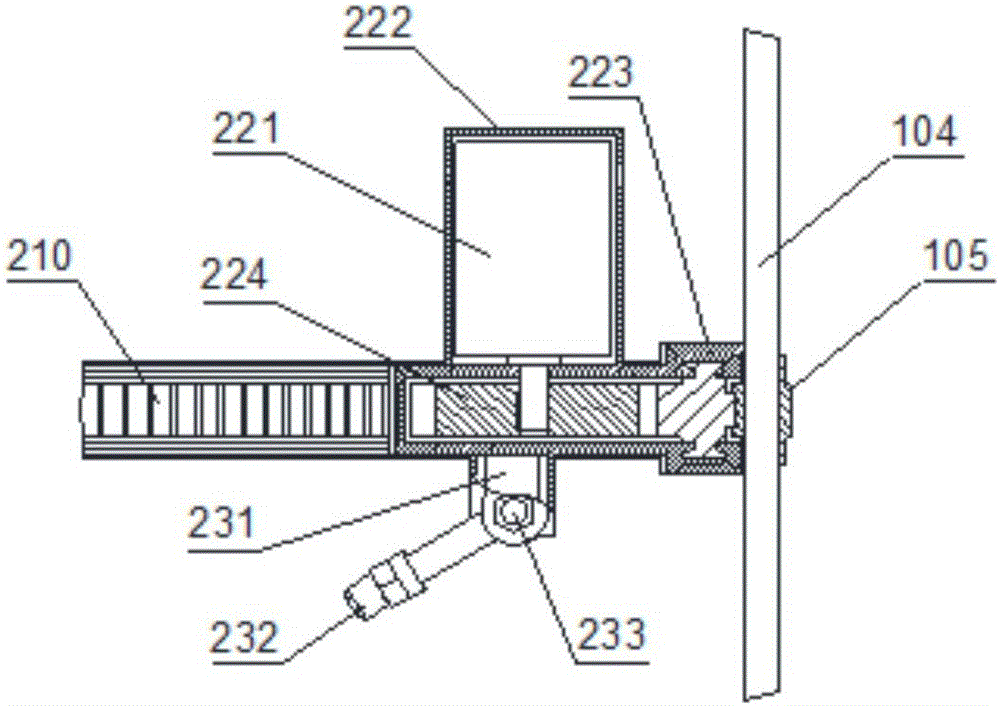

[0032] Such as figure 1 As shown, an insulator water flushing device includes a flushing mechanism 230 with a high-pressure water gun 232 for flushing the insulator through a water gun. The mechanism 220 is connected; the rotating mechanism 220 drives the flushing mechanism 230 to move along the circumferential direction of the insulator to realize the cleaning of the insulator circle.

[0033] In order to further expand the cleaning of insulators, multiple strings of insulator strings 400 are cleaned. The above-mentioned cleaning device also includes a lifting mechanism 100 arranged around the circumference of the insulator or on one side of the insulator. The lifting mechanism 100 and the flushing mechanism 230 are fixed to drive the flushing. The mechanism 230 moves along the axial direction of the insulator, thereby expanding the cleaning range of the device, which can not only realize the cleaning of the height range of the insulator, but also realize the cleaning of the ...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] The lifting mechanism includes a lifting power source. The lifting power source is fixed to the rack through the support plate to drive the rack to move along the axial direction of the insulator. The support plate can be arranged in multiple places along the circumference of the insulator.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is:

[0050] There is a hollow ring in the middle of the fixing piece to pass through the insulator string through the hollow ring, and the hollow ring is a whole structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com