A nailing method for the production of wooden pallets

A technology for wooden pallets and nail guns, applied in nailing tools, U-shaped nailing tools, rigid containers, etc., can solve the problems of low nailing efficiency and difficulty in ensuring the quality of wooden pallets, and achieve high production efficiency and improved nailing Quality, the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

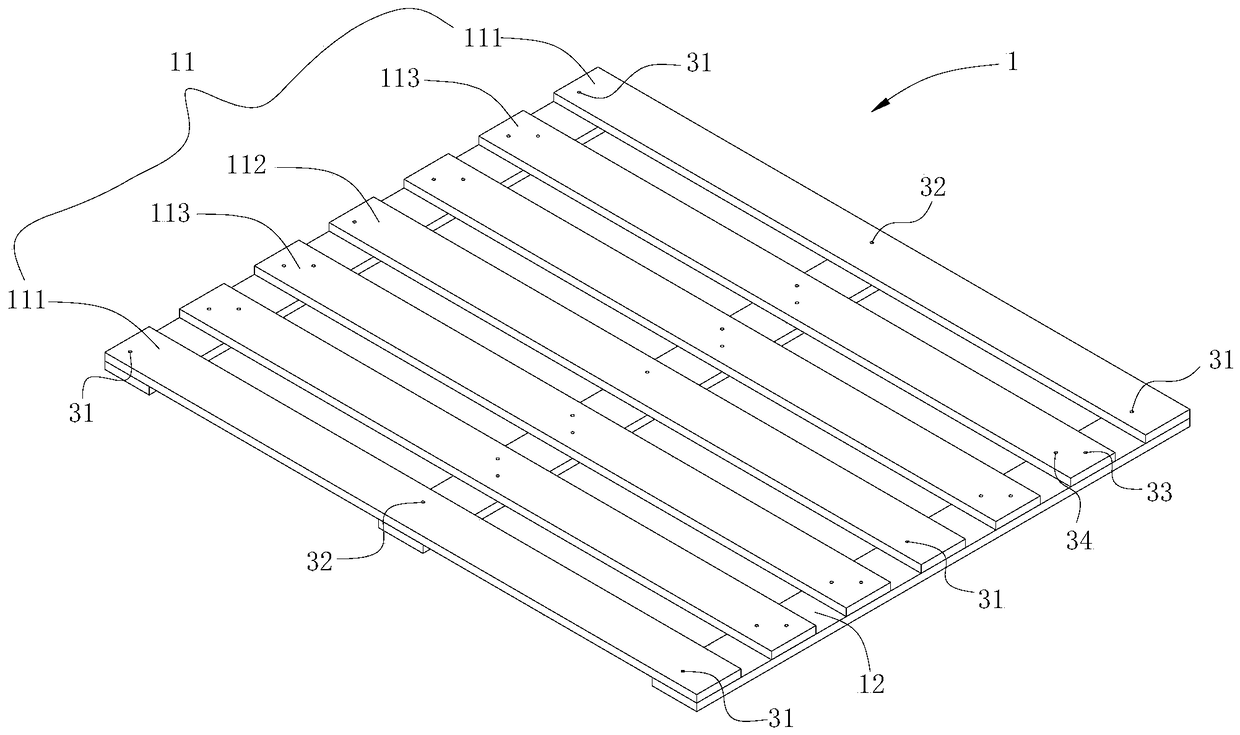

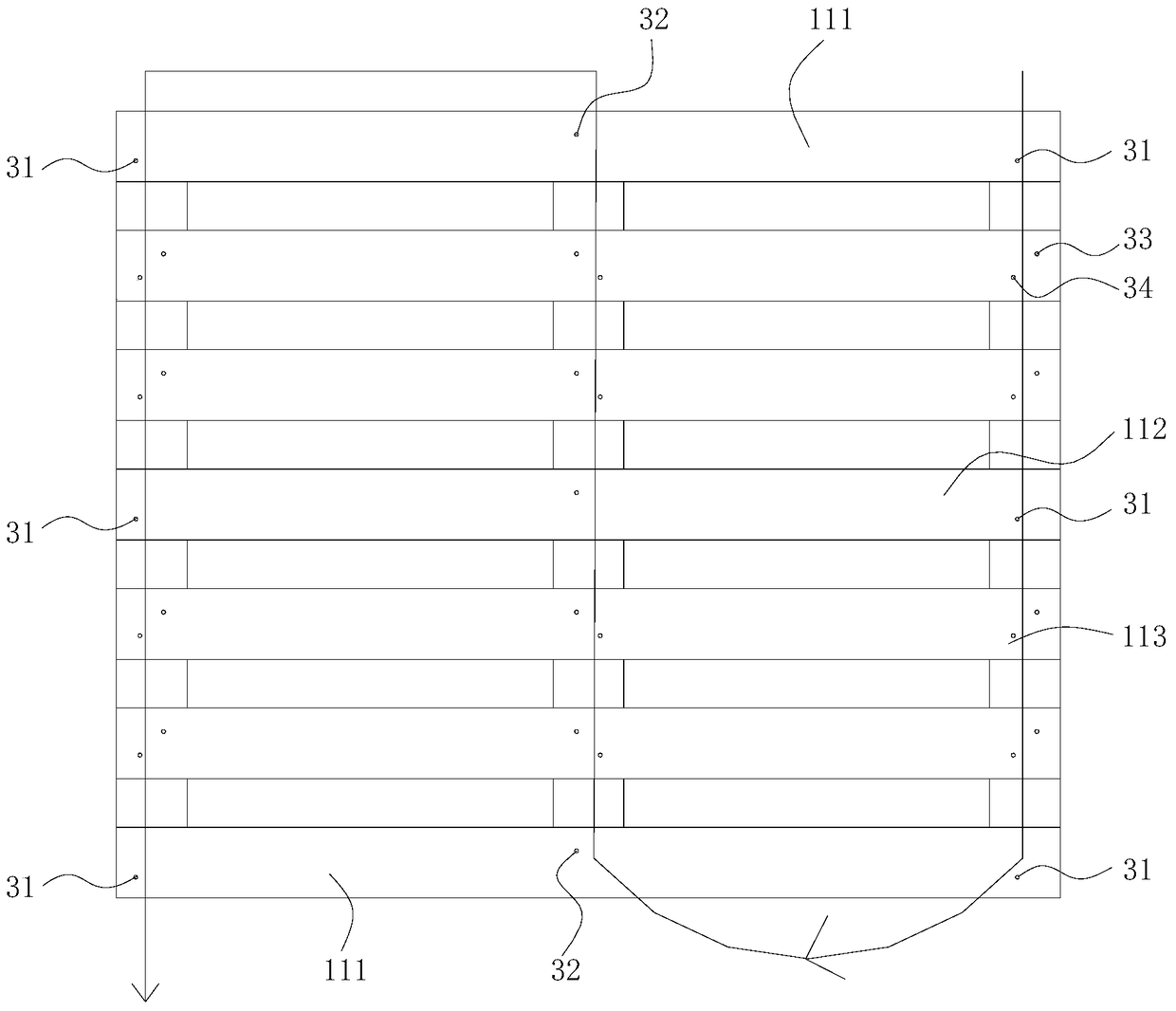

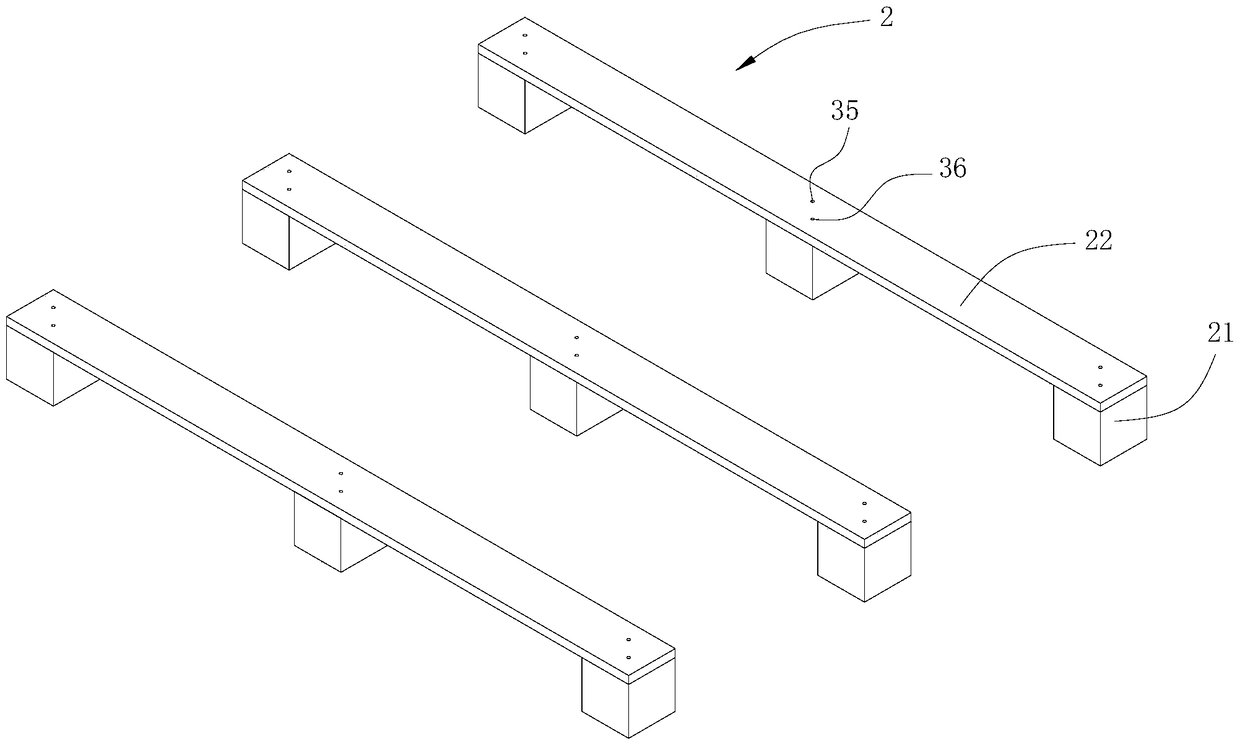

[0025] The wooden pallets commonly used in the wood packaging industry generally include a panel 1 and a base 2. The panel 1 is nailed together by a horizontal slat 11 extending in the horizontal direction and a longitudinal slat 12 extending in the longitudinal direction. The base 2 is composed of a wooden pier 21 and Bottom plate 22 is nailed together by nails, general wooden pallet, transverse lath 11 comprises the first transverse lath 111 that is positioned at the opposite end of panel 1, the second transverse lath 112 that is positioned at the middle of panel 1, except the first transverse lath 112. 111 and the third transverse slat 113 other than the second transverse slat 112, the longitudinal slat 12 is arranged on the other opposite ends and the middle of the panel 1 respectively, and the base 2 has multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com