Infinite space standard vector force calibration device

A calibration device, vector force technology, applied in the direction of measuring devices, force/torque/work measuring instrument calibration/testing, instruments, etc. The direction is accurate, conducive to accurate measurement, and the effect of small mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

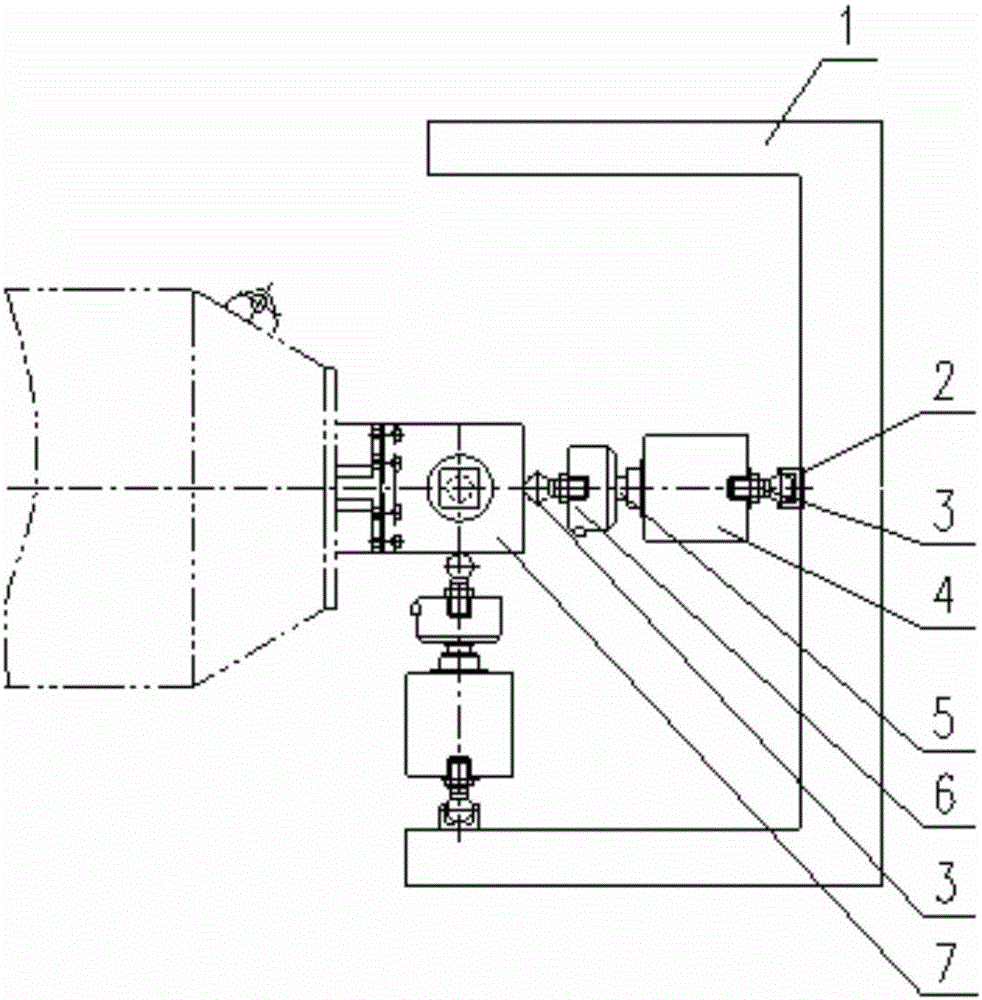

[0016] See attached figure 1 As shown, this kind of stepless space standard vector force calibration device is characterized in that: the device includes a gantry frame 1, three sets of calibration components for generating standard force are installed on the gantry frame 1, and the gantry frame 1 is fixed on the ground , used to support three calibration components, the three calibration components are arranged according to (X / Y / Z) perpendicular to each other, that is, the directions of the forces generated by the three calibration components are X, Y, Z respectively, and the three calibration components generate force The directions intersect at one point in space, and this point is located on the central axis of the aviation simulation engine. Each set of calibration components includes a connecting seat 2 installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com