Simulation load assembly capable of improving testing precision and applied to automobile cable testing machine

A cable testing machine and a technology for simulating loads, which are used in vehicle testing, mechanical component testing, machine/structural component testing, etc. Problems such as large measurement limitations, to achieve the effect of improving measurement limitations, ensuring accuracy and stability, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

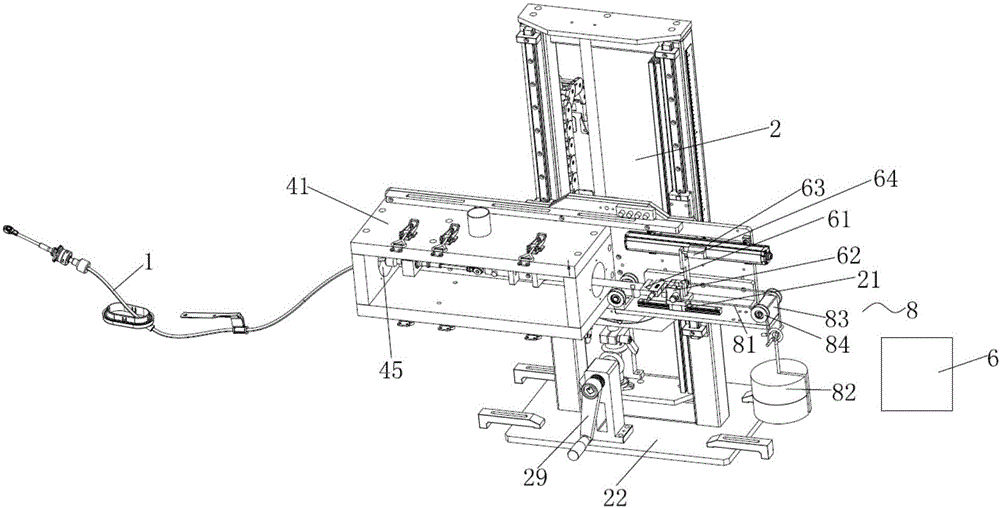

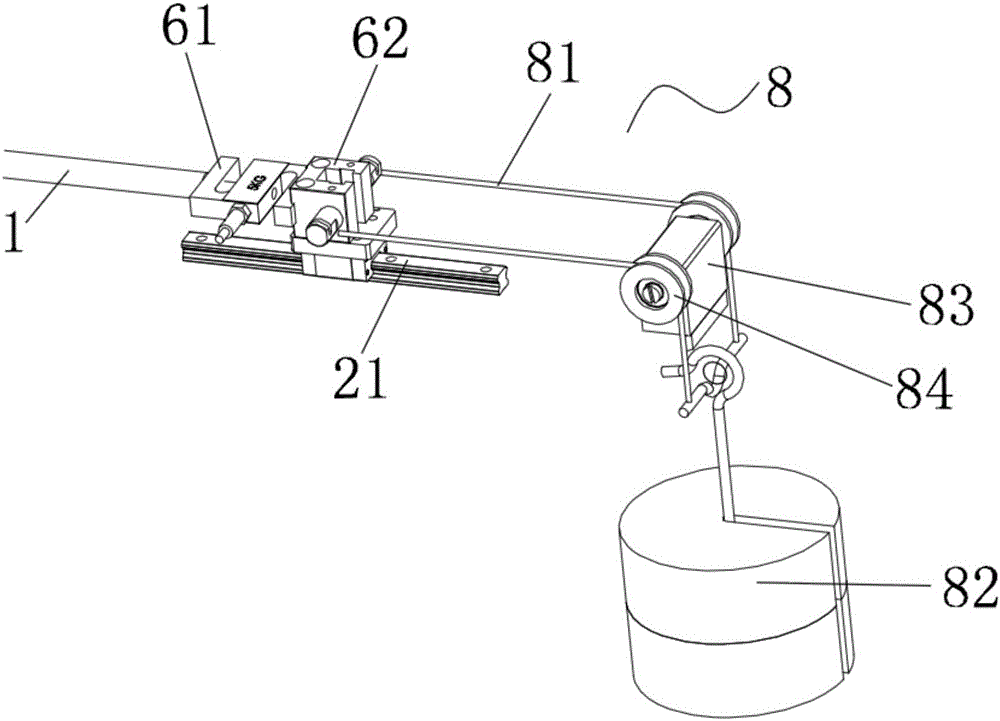

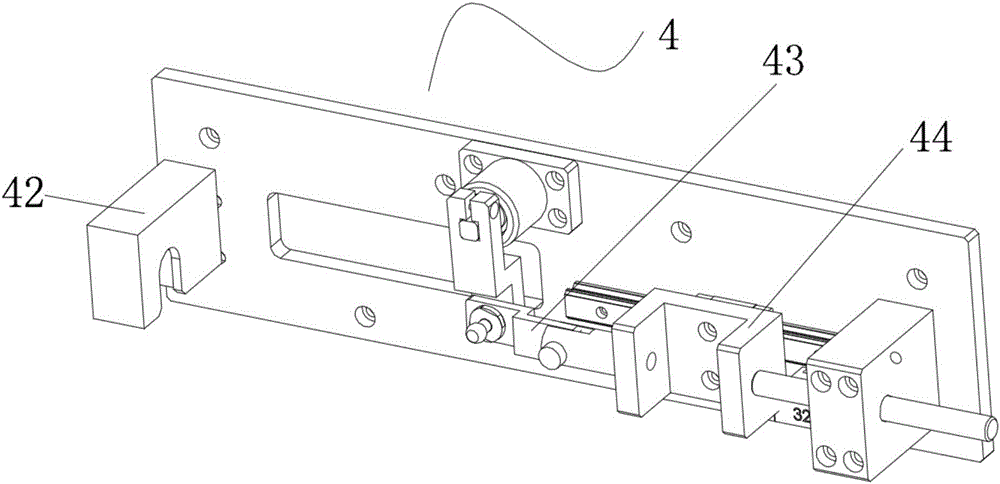

[0031] Such as figure 1 , 2 As shown, this embodiment discloses a simulated load assembly for an automobile cable detection machine that improves test accuracy, including an installation platform 2, a gearbox transmission simulator 4 fixed on the installation platform 2, a control device 6 and a load driver 8 for providing a power source to the load end of the vehicle cable 1, and a force sensor 61 connected between the transmission simulator 4 and the load driver 8, the vehicle cable 1 The load end passes through the transmission simulator 4 of the gearbox and connects the force sensor 61. The force sensor 61 is fixed on a connection seat 62. The installation machine 2 is also provided with a displacement sensor 63. The displacement sensor 63 The magnetic ring 64 is fixed on the connection seat 62, and the force sensor 61 and the displacement sensor 63 are all connected to the controller 6;

[0032] The load driver 8 includes a stay rope 81, a weight 82 and a guide seat 83 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com