Open pressure-adjustable submerged jetting water tunnel and flow field forming method thereof

A pressure-adjustable, jet-type technology, which is applied in fluid dynamics tests, machine/structural component tests, and measuring devices, can solve problems such as the inability to guarantee the quality of the flow field, and achieve the effect of eliminating the wall effect and achieving good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

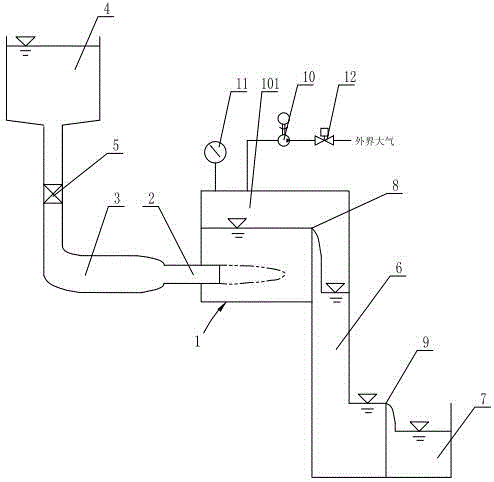

[0024] See figure 1 According to the present invention, the open-type adjustable pressure submerged jet water hole includes a working water tank 1, and the side wall of the working water tank 1 is provided with a flow channel communicating with the working water tank 1, and the flow channel includes a horizontal rectifying section 2 connected in sequence and The drainage section 3 communicates with the upstream water source 4, and the drainage section 3 is provided with a speed regulating valve 5; the working water tank 1 includes a pressure regulating chamber 101 at the top, and in the working water tank 1, the space below the pressure regulating chamber 101 is divided into The test area and the pressure regulating section, the lower part of the pressure regulating chamber 101 communicates with the test area and the pressure regulating se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com