Calibration device for test measuring beam of wave load of ship

A technology of wave load and calibration device, which is applied in the direction of measuring device, hydrodynamic test, machine/structural component test, etc., to achieve the effect of compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

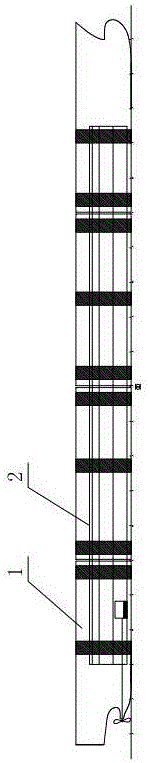

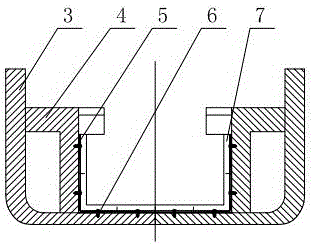

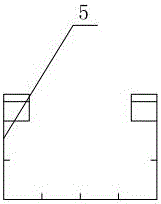

[0029] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the ship wave load test measuring beam calibration device of the present embodiment includes a ship model 1, a measuring beam 2 is installed in the ship model 1, and the shell 3 of the ship model 1 becomes a concave structure, and the ship model 1 shell 3 is internally installed with multiple A reinforced frame 4, the two ends of the reinforced frame 4 and the shell 3 form a hollow structure, the inner wall of the reinforced frame 4 is equipped with a transverse frame 7 through a backing plate 5 and a fastening screw 6; the calibration device of the measuring beam 2 is: including two There are loading support stools 9 arranged at intervals, a support frame 8 is installed on the top of the load support stool 9, a measuring beam 2 is placed in the support frame 8, and loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com