Auto-balancing secondary pressure maintaining sediment sampler

A technology of secondary sampling and secondary pressure holding, applied in the field of in-situ analysis and detection of deep-sea sediments, can solve problems such as unfavorable pressure stability, affecting detection results, polluting samples, etc., and achieve the effect of overcoming the requirements of space and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

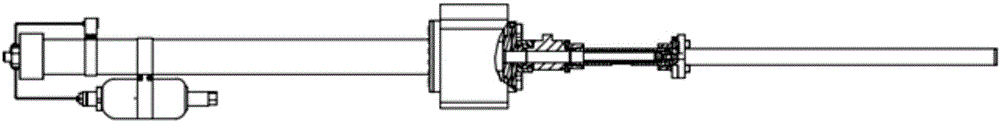

[0027] Such as Figure 4 A self-balancing secondary pressure-holding sediment sampler shown mainly includes a secondary sampling mechanical structure part and a pressure self-balancing part.

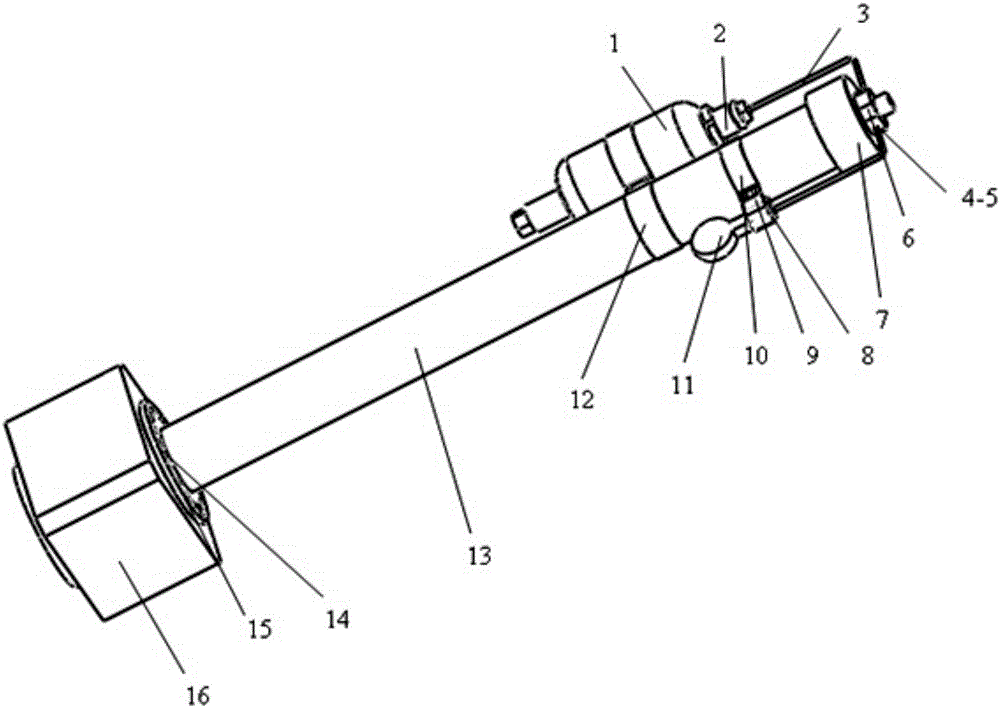

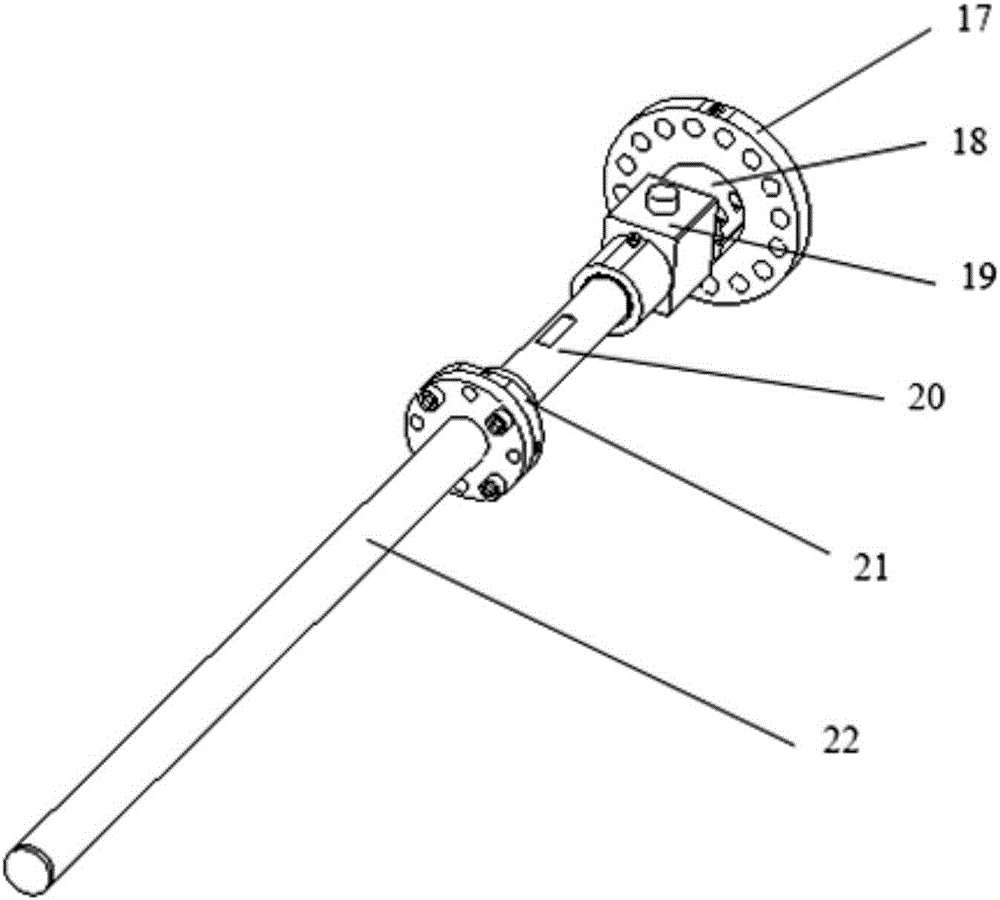

[0028] The mechanical structure part of secondary sampling mainly includes two sub-parts of transfer and sampling. The transfer part mainly includes a transfer cylinder 13, a transfer cylinder end cap 6, a transfer cylinder cap 7, an accumulator A1, an accumulator connection block 2, a capillary 3, a capillary pressure ring 4, a capillary pressure cap 5, a flange A14, Ball valve A16. The sampling part mainly includes a flange B17, a hoop 18, a ball valve B19, a pressure holding cylinder 20, a small sample tube 24, a flange C21, a connecting sleeve 25, and a hydraulic cylinder 22.

[0029] like figure 1As shown, one end of the transfer cylinder 13 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com