Slip preventive suspension clamp

A suspension clamp and anti-slip technology, which is applied in the direction of the cable suspension device, can solve the problems of bolt bending deformation, loose wire, easy to form corona, etc., and achieve the effect of avoiding damage and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

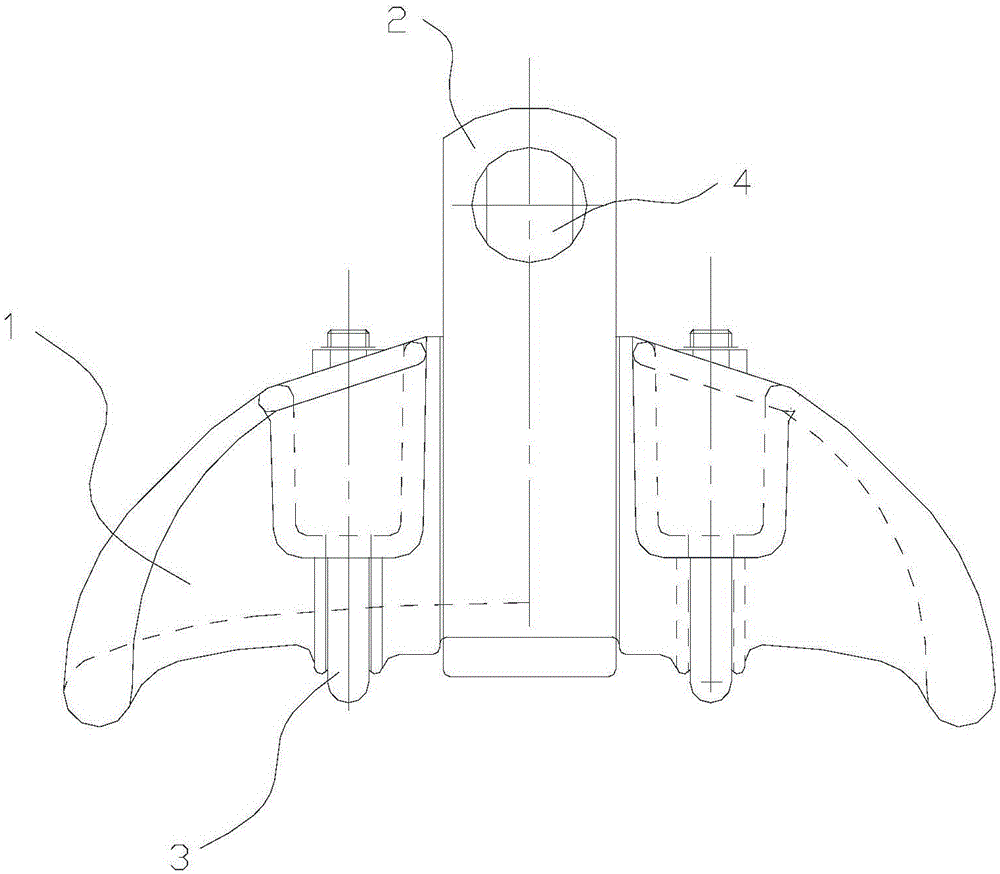

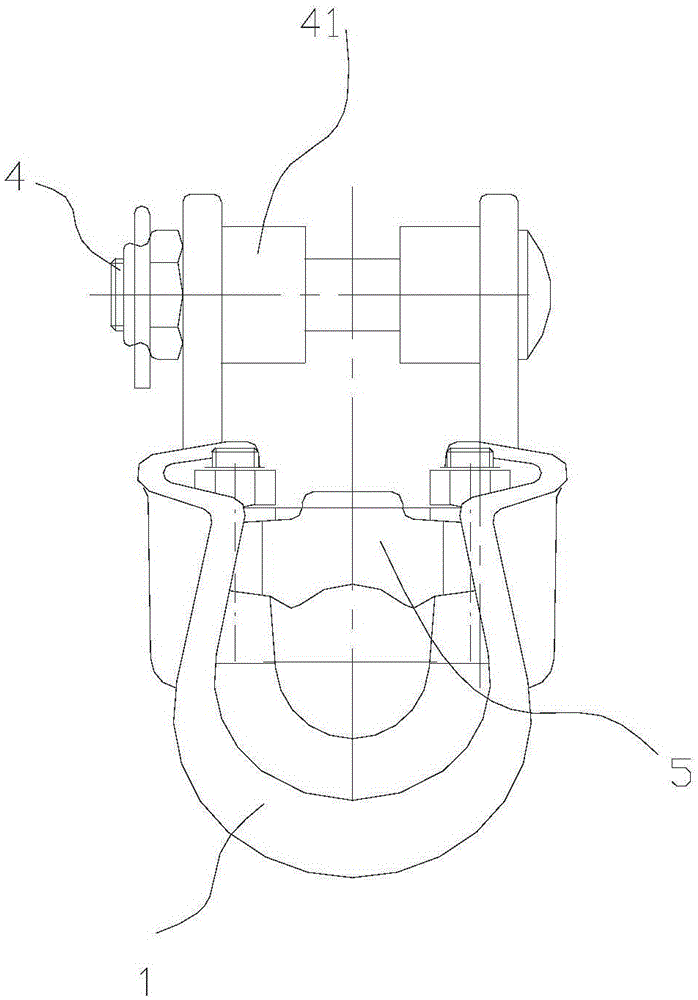

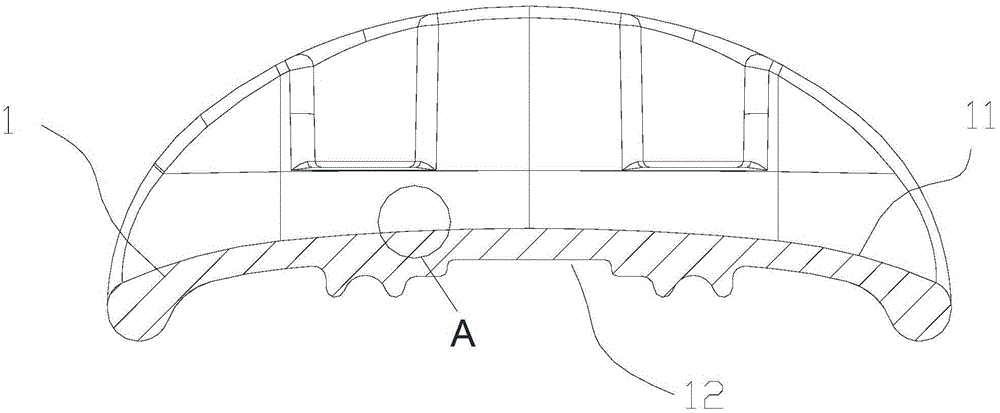

[0021] The invention is like Figure 1-6 As shown, it includes a cover plate 5, a body 1 with a U-shaped cross section, and a U-shaped hoop 2. The cover plate 5 is connected to the U-shaped groove of the body 1 by a pair of U-shaped bolts 3. The U-shape of the hoop 2 The mouth facing upward pocket is clamped in the middle of the body 1. The inner bottom surface of the body 1 is a wire passing groove 11, which is composed of three arcs, including a middle section and a symmetrical head and tail section. The middle section has a curvature radius The radius of curvature is larger than the symmetrical head and tail section; the surface of the middle section is provided with a number of serrations 111 protrusions.

[0022] The saw tooth 111 is a straight line perpendicular to the length direction of the body.

[0023] The serration 111 is a transverse arc; taking the center of the body as a reference, the serrations on both sides of the center of the body are symmetrical. Such as Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap