Positioning punching die

A technology for positioning punches and molds, applied in metal processing, etc., can solve the problems of high labor intensity, inability to process automatically, and high risk of work-related injuries, and achieve the effects of improving efficiency, saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

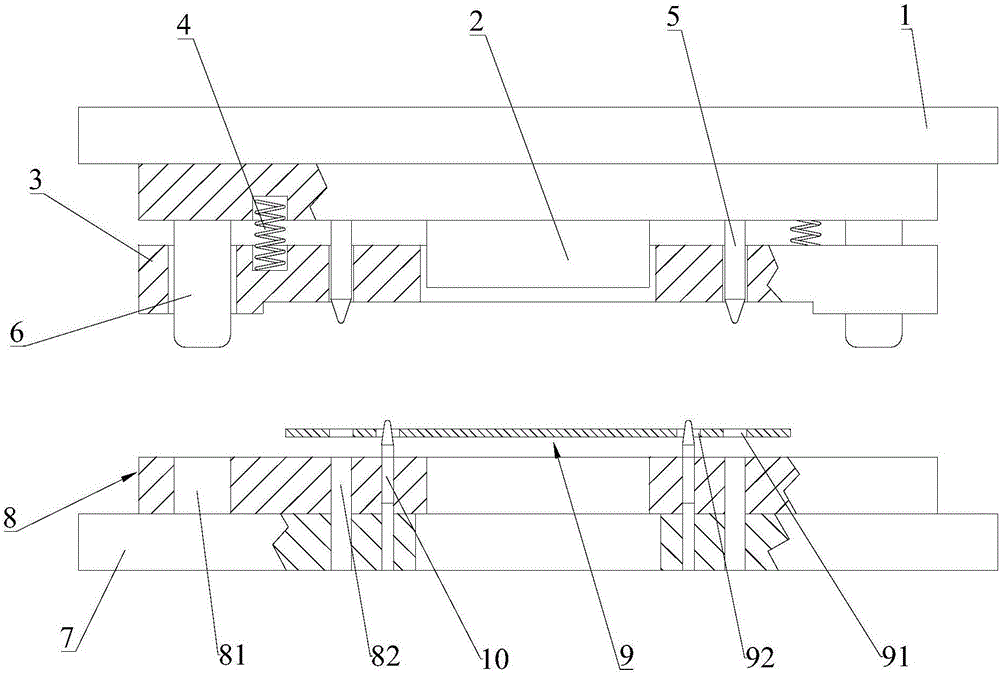

[0026] Please refer to figure 1 , Embodiment 1 of the present invention is: a positioning punching die for punching FPC products 9 . It includes an upper mold and a lower mold, and the lower mold is located below the upper mold. The FPC product 9 to be punched is provided with a first positioning hole 92 and a second positioning hole 91 . The first positioning hole 92 does not need to be dedicated, and the used positioning hole of the previous process can be used.

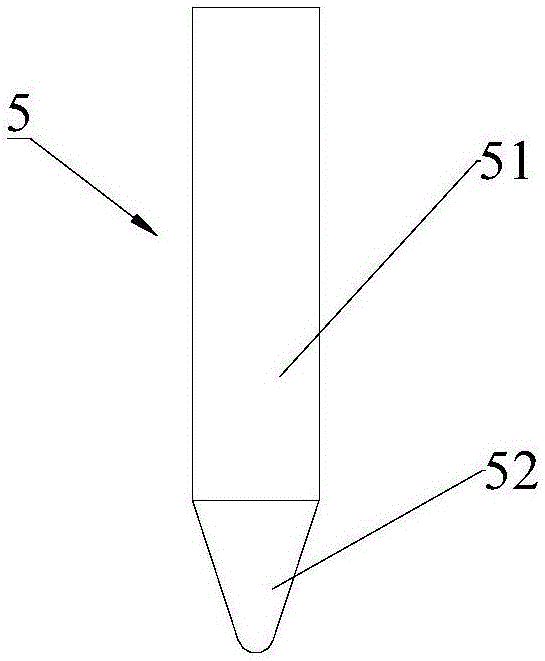

[0027] The upper mold includes an upper mold installation base plate 1, a punch 2 and an upper mold stripping plate 3, the punch 2 is fixed on the bottom of the upper mold installation base plate 1, and the upper mold stripping plate 3 is connected to the bottom of the punch 2 by a spring 4 connect. When in the original state, the bottom of the punch 2 is indented in the stripping plate 3 of the upper die, and when punching, the spring 4 is compressed, and the punch 2 stretches out of the stripping plate 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com