Kidney shape hole punching forming system and method of loudspeaker basin frame

A loudspeaker pot frame and stamping forming technology, which is applied in the direction of perforating tools, metal processing equipment, manufacturing tools, etc., can solve the problems of punch deflection and affecting the quality of punching, and achieve good positioning and good punching quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

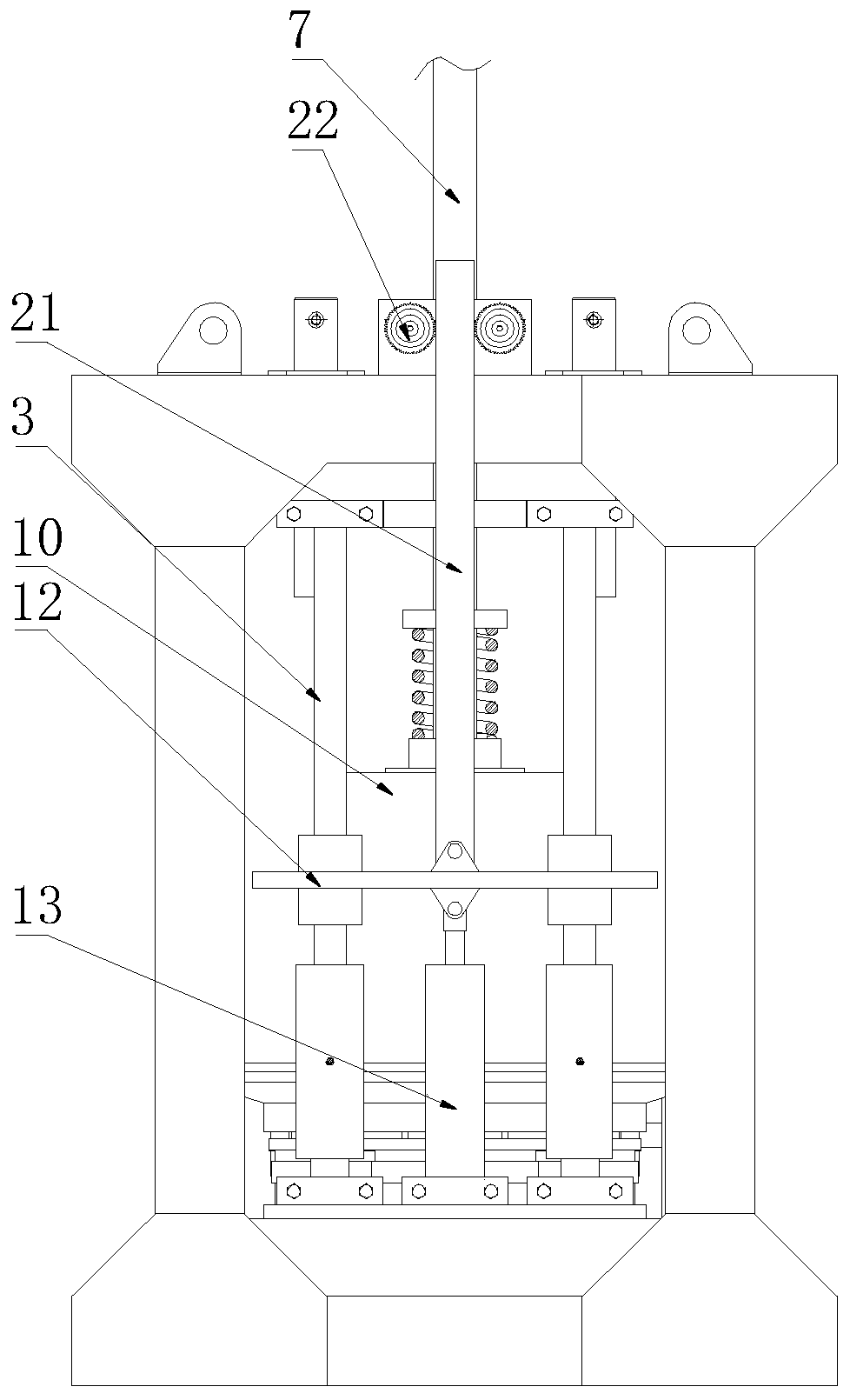

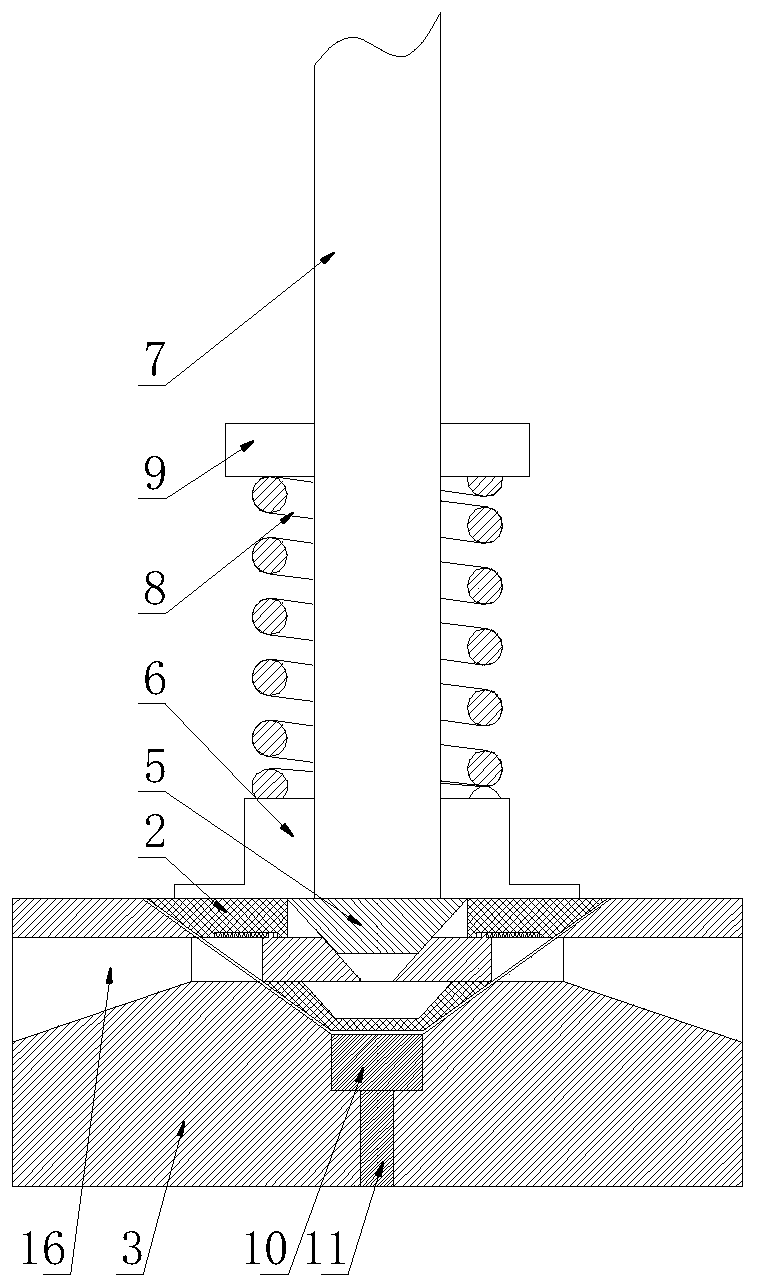

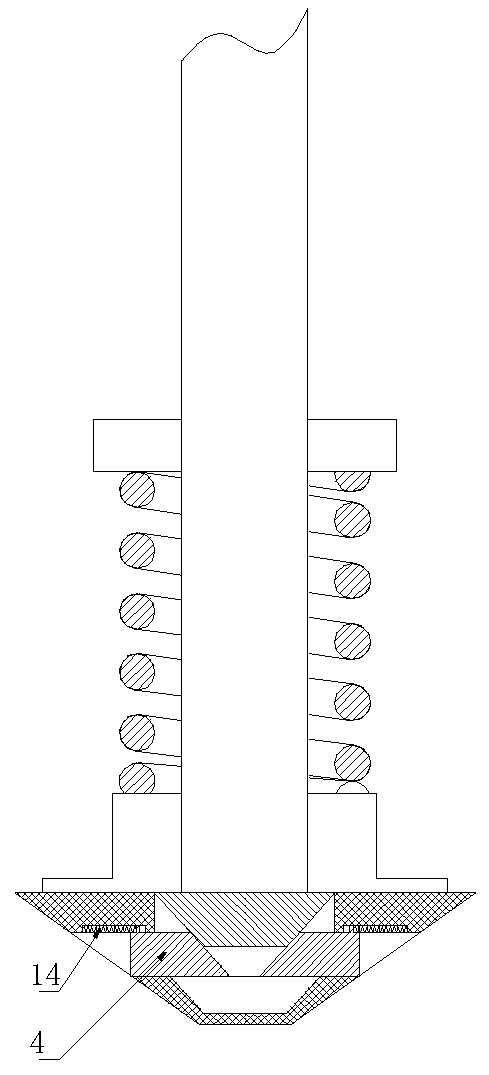

[0034] see Figure 1-3 , a loudspeaker frame waist hole stamping and forming system, including a frame 1 and a stamping die set, the stamping die set is installed on the frame 1, the stamping die set includes an upper die 2 and a lower die 3, and the inside of the upper die 2 A punch mechanism is provided, and the punch mechanism includes several punching blocks 4 uniformly distributed in an annular array. The inner surface of the punching block 4 is an inclined plane; There are several inclined surfaces that are wedged with the inner surface of the punching block 4;

[0035] The center of the upper die 2 is provided with a blind hole that cooperates with the inner punch 5, and the side of the upper die 2 is provided with a rectangular hole that cooperates with the punching block 4, and the rectangular hole communicates with the blind hole; The channel for movement, the bottom of the blind hole and the bottom of the inner punch 5 clearance fit; the rectangular hole provides a...

Embodiment 2

[0050] On the basis of Embodiment 1, in order to improve the accuracy of the demoulding and reset of the lower mold 3, a synchronous mechanism is provided on the frame 1. The synchronous mechanism includes double-sided racks 21 installed on the front and rear sides of the sliding seat 12. Two double-sided racks 21 mesh with the front and rear gears 22 on the top of the frame 1 respectively. The gears 22 are installed on the gear seat through the gear shaft, and the gear shafts of the gears 22 on the front and rear sides of the top of the frame 1 are connected by connecting rods. . The double-sided rack 21 meshes with the gear 22, and the gear shafts on the front and rear sides are connected as a whole to maintain the synchronous movement of the double-sided rack 21 on both sides. When the front and rear ends of the sliding seat 12 deviate, the sliding seat 12 will be corrected by the rack. The two sides move synchronously to avoid the sliding seat 12 and the lower mold 3 from ...

Embodiment 3

[0052] see Figure 4 , on the basis of Embodiment 1, the left side of the lower mold 3 is provided with an auxiliary demoulding mechanism, the auxiliary demoulding mechanism includes an auxiliary demoulding hydraulic cylinder 23 fixedly installed on the frame 1, and the piston of the auxiliary demoulding hydraulic cylinder 23 Rod connects push plate 24, is positioned at the left side of lower mold 3, drives push plate 24 to move to the right by the piston movement of auxiliary demoulding hydraulic cylinder 23 when lower mold 3 moves down, promotes the loudspeaker basin frame on the lower mold 3 to break away from.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com