Double-execution-unit hydraulic machine

A technology of hydraulic press and double execution, applied in the field of hydraulic press, can solve the problems of the complexity of the conversion process, the efficiency of energy utilization, the mismatch between the load characteristics and the drive, and the increase of energy conversion links, so as to reduce processing difficulty, improve flexibility, and satisfy The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

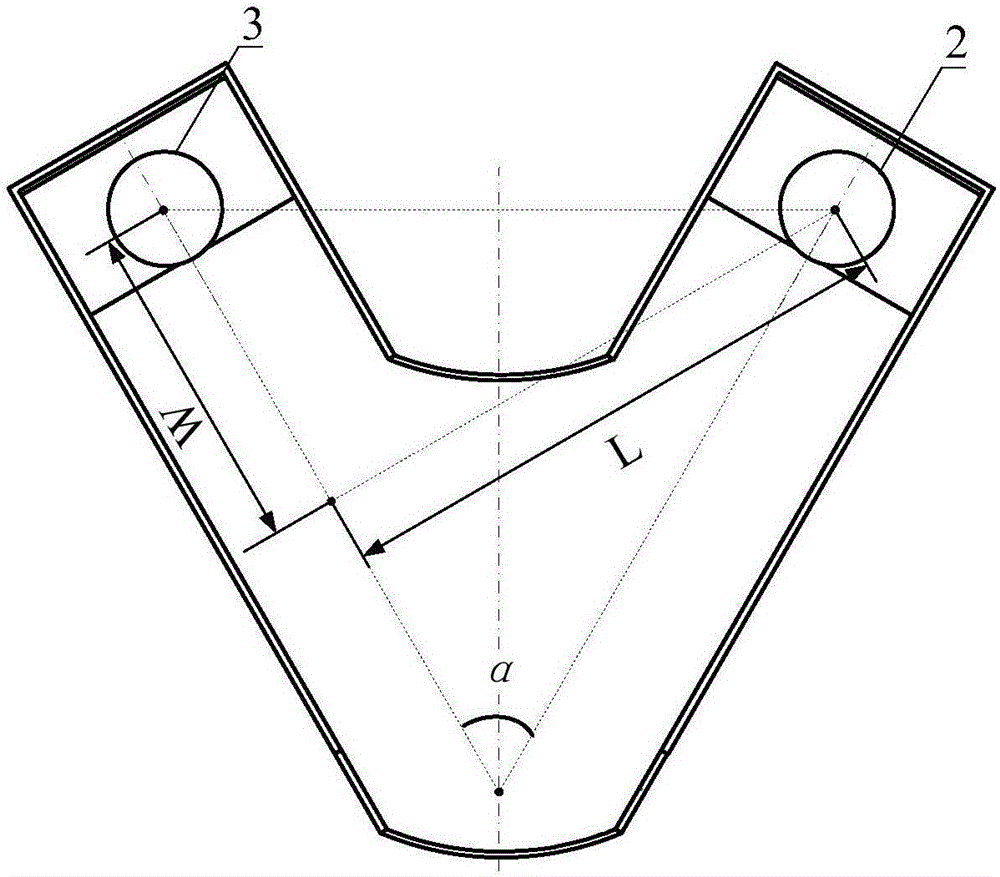

[0056] Implementation mode 1: if image 3 As shown, the top view shape of the hydraulic machine frame 1 is a "V" shape composed of the first arm and the second arm. In the "V" shape frame, the first hydraulic cylinder 2 is at the front end of the first arm, and the second hydraulic cylinder 3 is located at the front end of the second arm, and an operating space is formed between the first arm and the second arm. The distance between the cylinder body of the second hydraulic cylinder 3 and the cylinder body of the first hydraulic cylinder 2 is L, The left and right distance is W; and there are: the arm lengths of the first arm and the second arm are both L / sin2α; α is the angle between the first arm and the second arm, 0° In this structural form, the body frame is composed of two equal-length arms, which can meet the requirements of any relative position of the hydraulic cylinder, reduce the processing difficulty of the hydraulic machine frame, and improve the flexibility of the...

Embodiment approach 2

[0057] Implementation mode 2: if Figure 4 As shown, the top view shape of the hydraulic machine frame 1 is a rectangle, and the first hydraulic cylinder 2 and the second hydraulic cylinder 3 are arranged on the front side of the rectangular frame, and are located on the front side at a distance of W', one on the left and one on the right. . In this structural form, the two hydraulic cylinders are arranged side by side on the front side of the rectangular frame, so that the two hydraulic cylinders are within the range of manual operation, which meets the needs of improving the efficiency of the manual operation process and reduces the difficulty of manual operation.

Embodiment approach 3

[0058] Implementation mode 3: if Figure 5 As shown, the top view shape of the hydraulic machine frame 1 is elongated, and the first hydraulic cylinder 2 and the second hydraulic cylinder 3 are arranged one after the other at the front end and the rear end of the elongated frame. The first hydraulic cylinder 2 and the second hydraulic cylinder The front and back distance of the hydraulic cylinder 3 is L'. In this structural form, the two hydraulic cylinders are placed at the front and rear ends of the elongated frame to ensure that the auxiliary automatic loading and unloading devices of the two hydraulic cylinders do not affect each other. .

[0059] In this embodiment, the dual-execution unit hydraulic press is initialized according to the following steps:

[0060] Step 1: Start the liquid pump 8 and keep the liquid pump 8 in working condition;

[0061] Step 2: Adjust the state of the first valve group 10, the second right valve group 12a, the second valve group 12b and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com