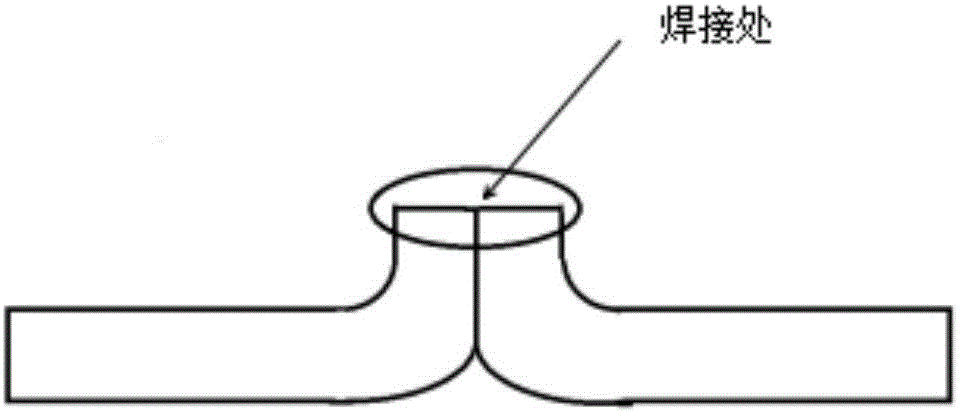

Simulation method for welding stress field of flanged edge joint

A technology of crimping joints and welding stress, applied in 3D modeling, special data processing applications, image data processing, etc., can solve problems such as unstable temperature field, unqualified welding, uneven weldments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] Specific Embodiment 1: A method for simulating the welding stress field of a curling joint in this embodiment is implemented in the following steps:

[0038] First, the welding conditions are determined. In this example, the conditions are: welding voltage U=30V, welding current I=250A, and welding speed 0.01m / s. The horizontal flanging of the weldment is 30mm, the vertical flanging is 20mm, the length is 100mm, and the thickness is 5mm. The weldment is symmetrical about the weld. Then proceed to the following steps:

[0039] Step 1: Define the element and material constants in ANSYS: the element type is defined as solid 70, and the material properties include thermal conductivity, density, specific heat capacity, Poisson's ratio, expansion coefficient, elastic modulus, and yield stress;

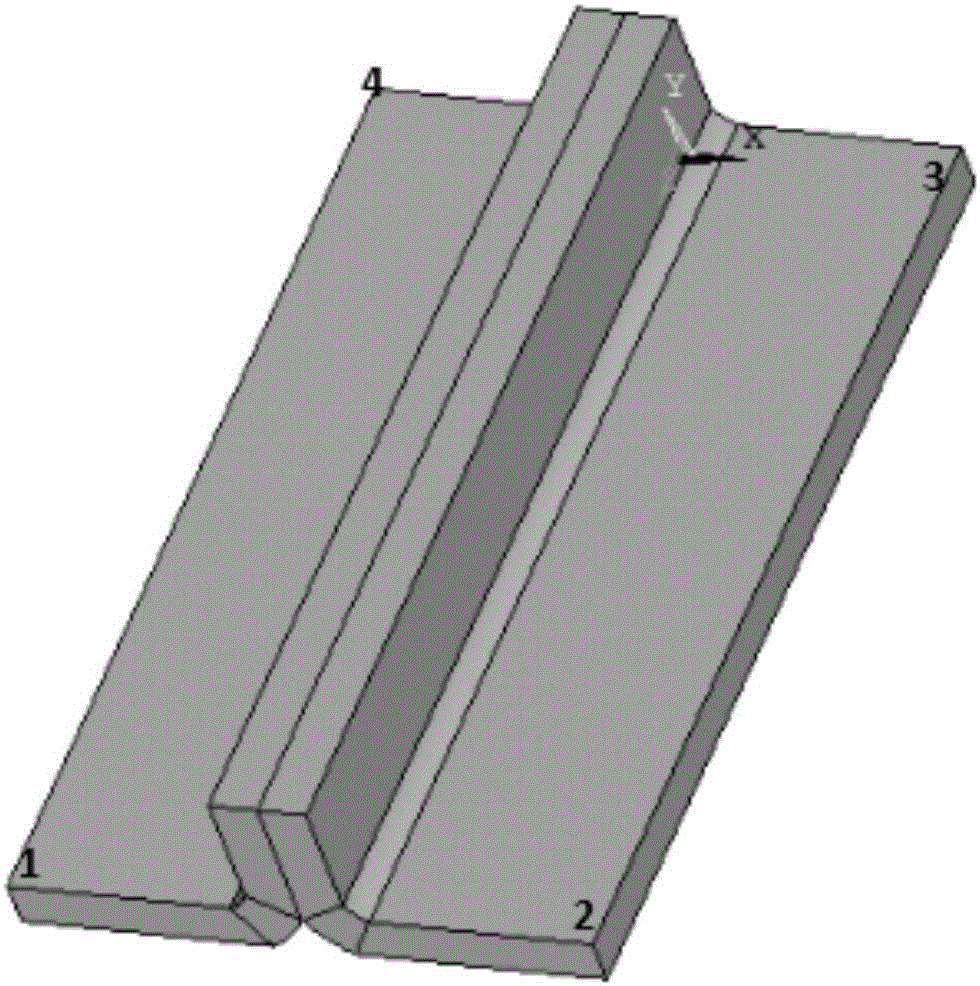

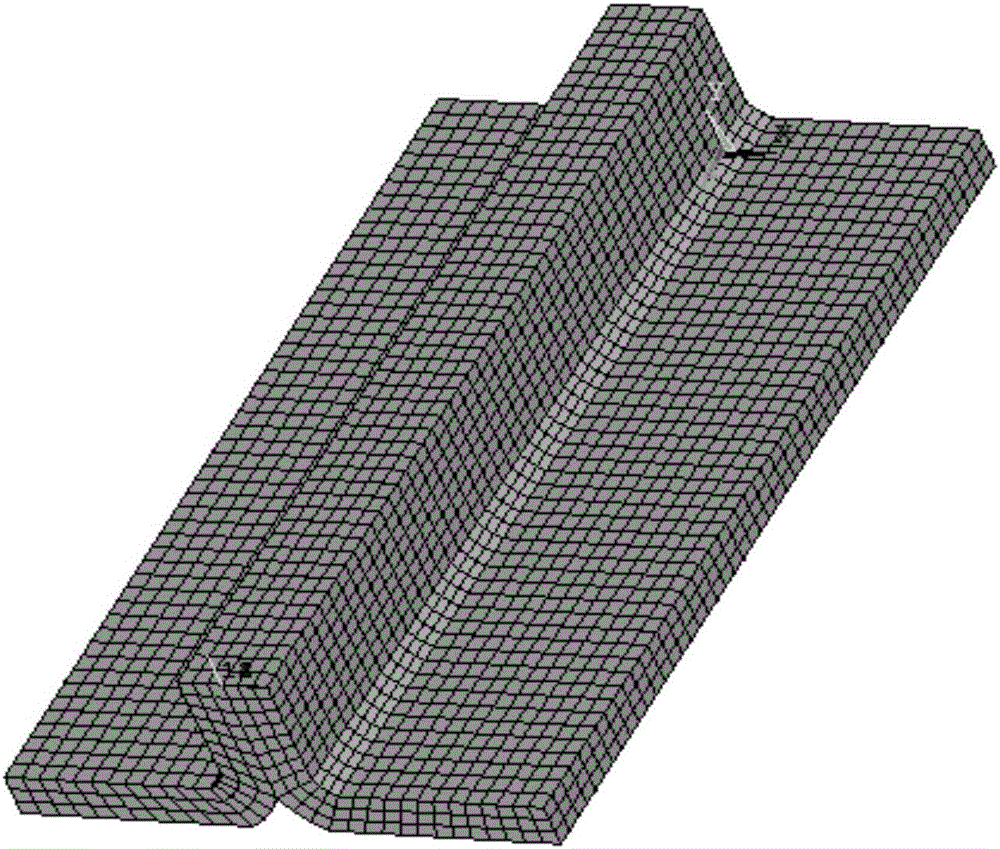

[0040] The second step: establish the seam joint model and mesh division: obtain the seam joint model by establishing key points and surfaces. Finally, the grid is divided, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap