A kind of electric vehicle charging cable and preparation method thereof

A charging cable and cable technology, which is applied in the direction of power cables with shielding layer/conductive layer, cable/conductor manufacturing, insulated cables, etc., can solve the problems of slow charging speed of charging cables, affecting the service life of cables, and easy damage, etc., to achieve Large current-carrying capacity, strong electrical conductivity, and small single-filament diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

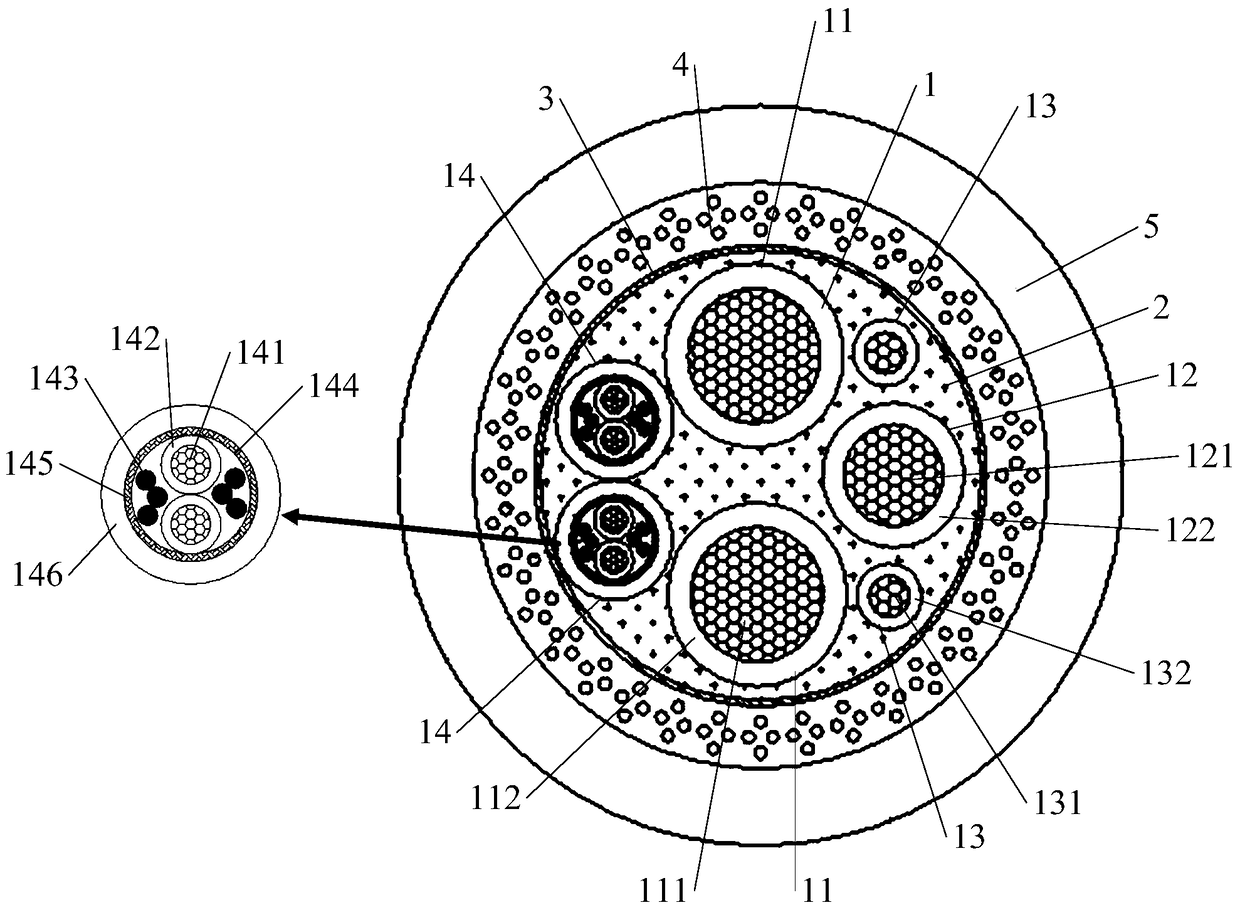

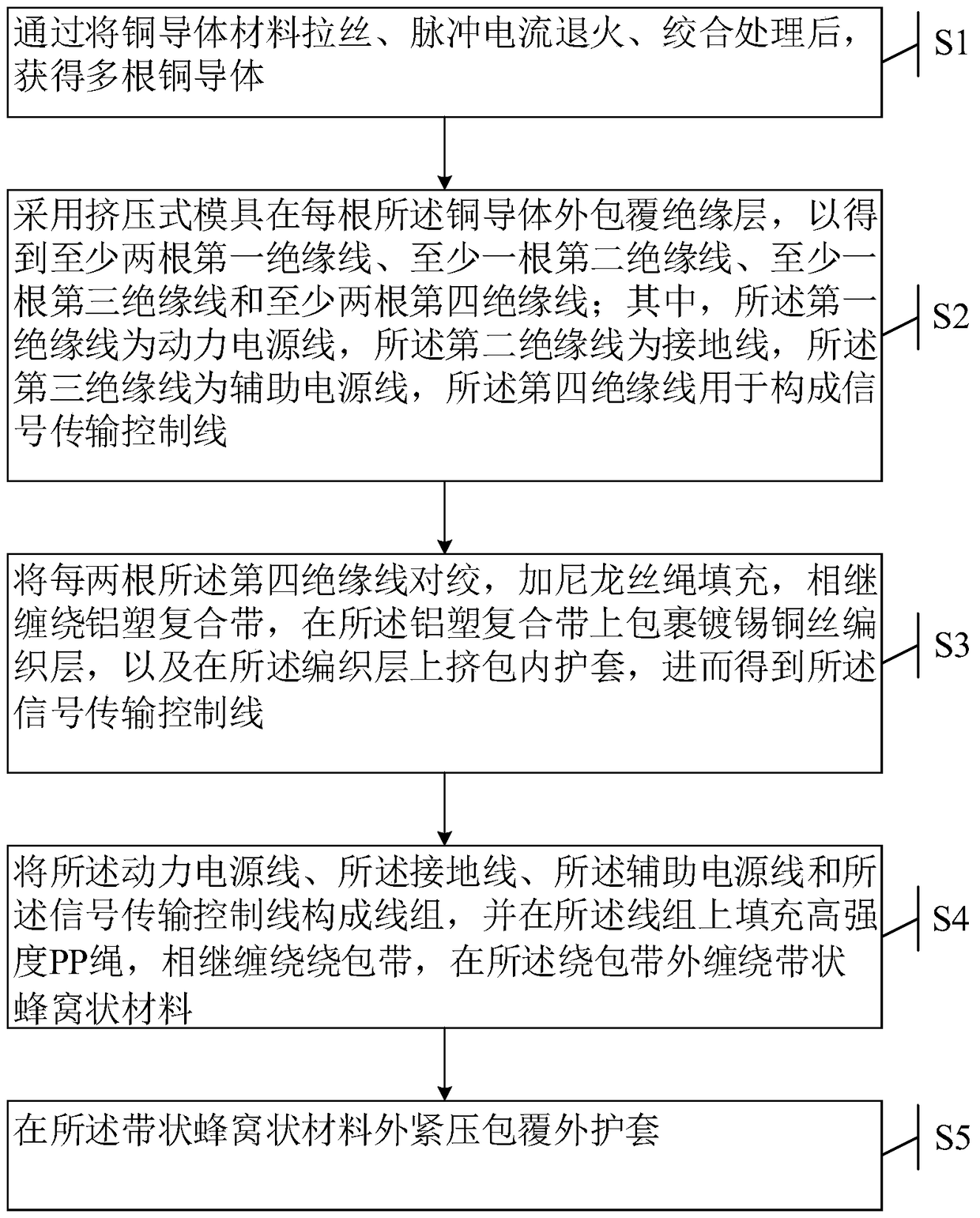

[0027] The embodiment of the present invention provides a charging cable for electric vehicles, which solves the technical problems in the prior art that the charging speed of the charging cable for electric vehicles is not fast, and is easily damaged after being frequently dragged. It can not only realize fast charging of electric vehicles, And it has the characteristics of twist resistance, rolling resistance and high tensile strength.

[0028] The technical solution of the embodiment of the present invention is to solve the above-mentioned technical problems, and the general idea is as follows:

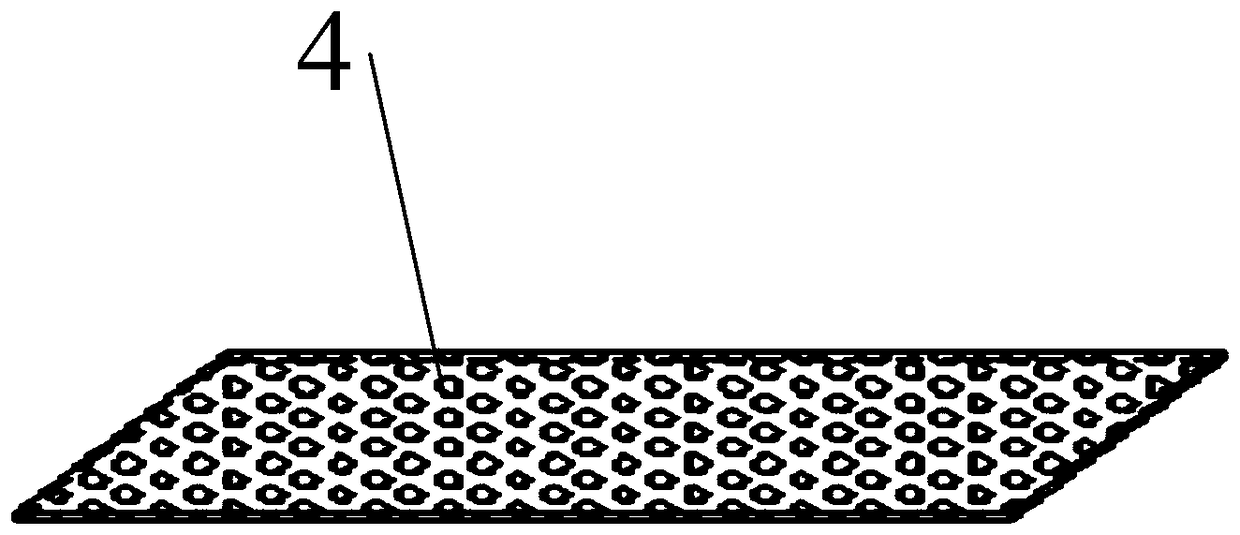

[0029] An embodiment of the present invention provides an electric vehicle charging cable, which includes: a cable inner core, a filling material, a wrapping tape, a strip-shaped honeycomb material, and an outer sheath from the inside to the outside; The power supply line for the charging current of the power supply, the grounding line for providing ground protection, the auxiliary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com