Condenser type touching control panel reducing line impedence by FPC

A capacitive touch and circuit technology, applied in the direction of electrical digital data processing, printed circuit components, electrical connection printed components, etc., can solve the difficulty of the manufacturing process of the capacitive touch panel 10, the increase in height, the low rate of good manufacturing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

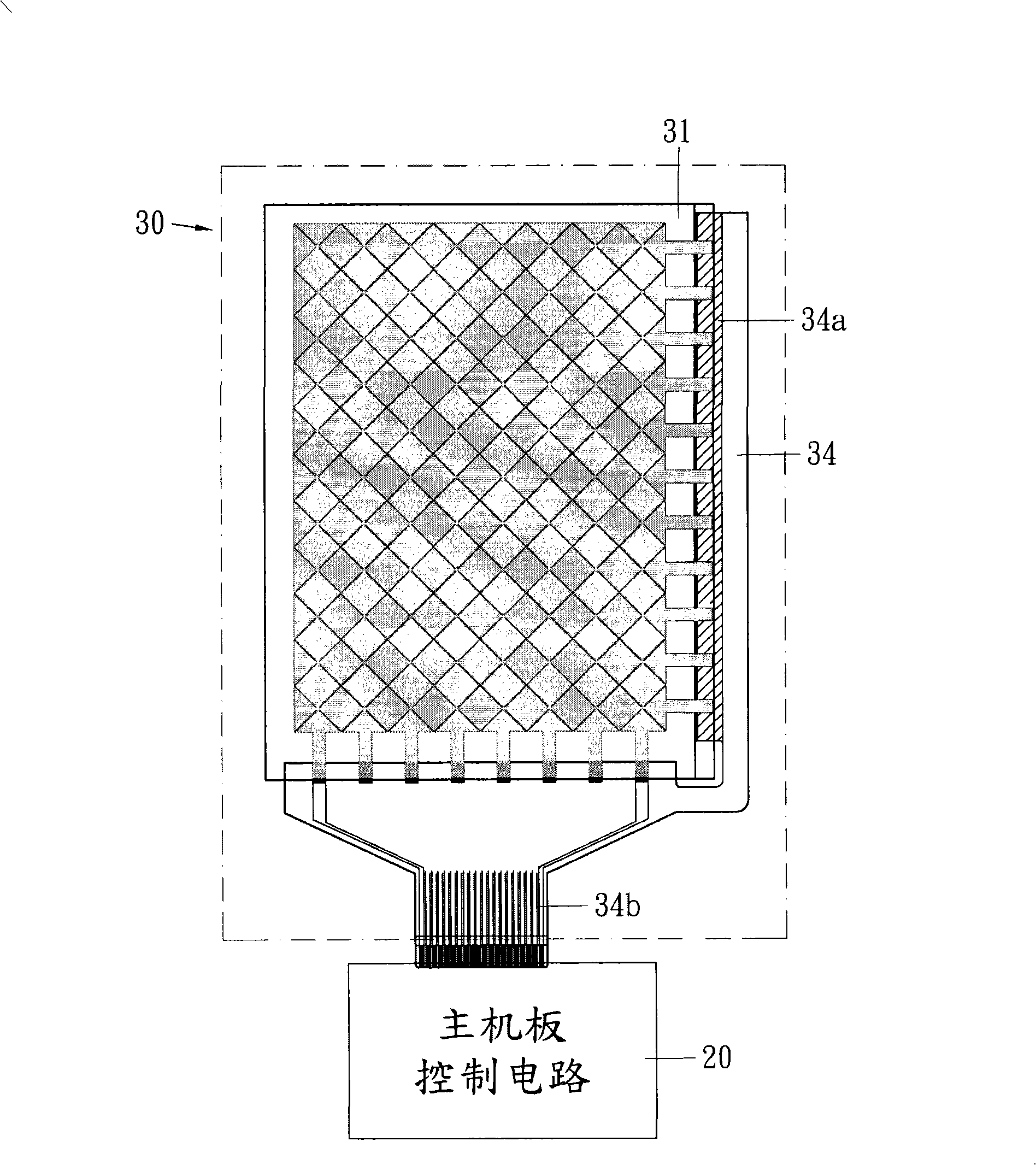

[0049] Such as Figure 4 As shown, a 3.9-inch capacitive touch panel 30 is used as a test sample, and its structure is to stack an X-direction sensing circuit layer 32 and a Y-direction sensing circuit layer 33 on the upper and lower sides of a 3.9-inch glass substrate 31, and use a device The flexible printed circuit board 34 with the wire circuit 34 a and the signal output circuit 34 b is electrically connected to the X-direction sensing circuit layer 32 and the Y-direction sensing circuit layer 33 .

[0050] The impedance of the capacitive touch panel 30 was measured with an HP 8248 LCR (inductance capacitance resistance) measuring instrument, and the results are shown in Table 1.

Embodiment 2

[0052] A 3.5-inch capacitive touch panel 30 is used as a test sample, and its structure is the same as that of the capacitive touch panel in Embodiment 1 except that a 3.5-inch glass substrate is used.

[0053] The impedance of the capacitive touch panel 30 was measured with the same equipment, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com