Motor for oil field drilling

An oil field drilling and armature technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of unusable motors, high prices, and inconvenient purchases, and achieve the effects of easy maintenance, high reliability, and strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

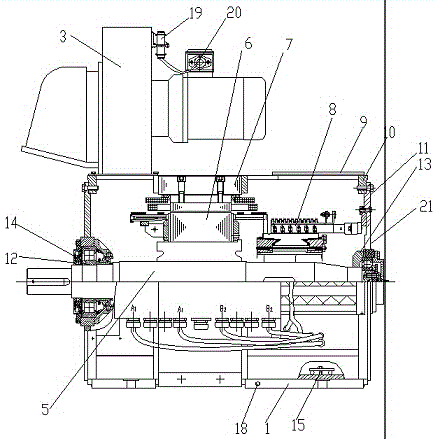

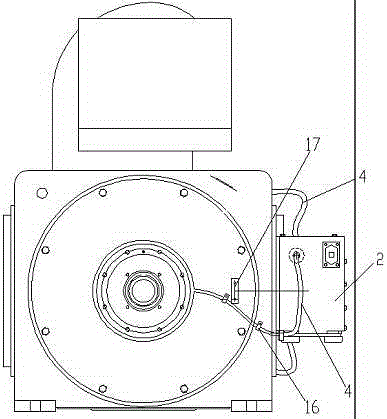

[0012] Such as figure 1 and figure 2 A motor used for oil field drilling is shown, including a base 1 and a motor body. A junction box 2 is provided on one side of the motor body, and an explosion-proof fan 3 is provided on the top. Both the junction box 2 and the explosion-proof fan 3 are connected to the motor through an explosion-proof pipe 4 The main body, the motor body includes a main shaft 5, an armature 6, a stator 7, and a brush holder 8. The brush holder 8 is arranged on one side of the armature 6, and a cover plate 9 is arranged on the motor body at the top of the brush holder 8, and a cover plate 9 is arranged on the motor body on one side. An end cover 10 and a pressure plate 11 are provided, a first rolling bearing assembly 12 and a second rolling bearing assembly 13 are respectively provided at both ends of the main shaft 5, the first rolling bearing assembly 12 is sealed by a labyrinth bearing sealing structure 14, and a heater device 15 is also included in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com