Special bidirectional liquid-outlet filter board for filter press

A filter plate and filter machine technology, which is applied in the field of special filter plates for two-way outlet hydraulic filters, can solve the problems of increasing the difficulty and time of cake lowering, slow liquid outlet speed, and small amount of liquid outlet, and achieves good clamping effect, The effect of reducing the liquid content and increasing the liquid output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

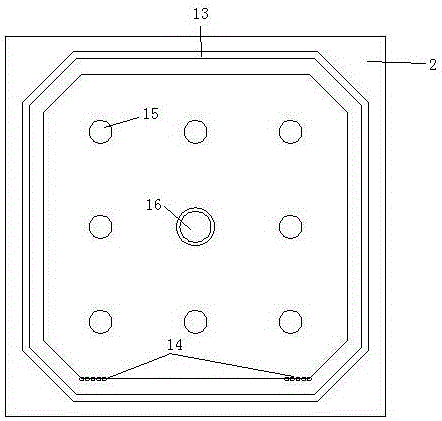

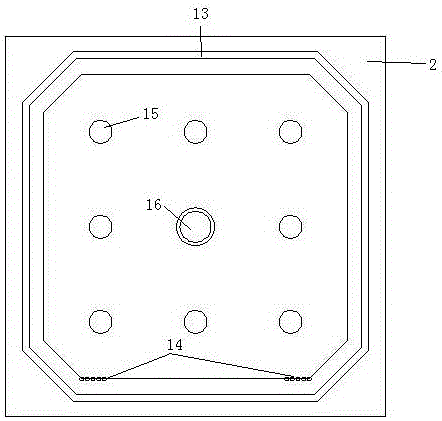

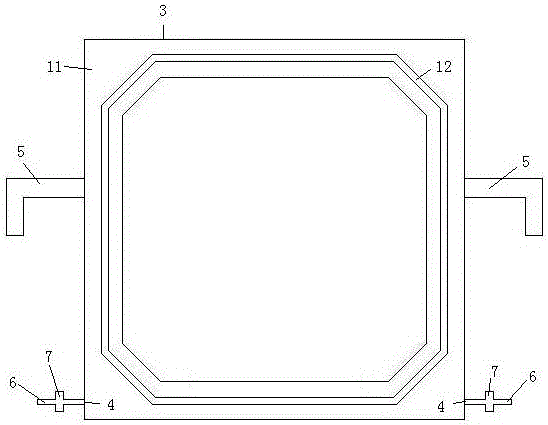

[0014] As shown in the figure, a special filter plate for a two-way outlet hydraulic filter includes a filter plate 1. The filter plate 1 includes an inner plate 2 and a splint 3. The inner plate 2 is located in the splint 3. The splint 3 Both sides are provided with a liquid outlet 4 and a support frame 5, the liquid outlet 4 is provided with a liquid outlet nozzle 6, and the liquid outlet nozzle 6 is provided with a control valve 7, and the support The frame 5 includes a first support plate 8 and a second support plate 9, the first support plate 8 and the second support plate 9 are vertically arranged, the described splint 3 includes a first splint 10 and a second splint 11, the described The first splint 10 and the second splint 11 have the same size and shape, and the first splint 10 and the second splint 11 are provided with a mounting groove 12, and the mounting groove 12 is an octagonal structure, so The inner panel 2 is a square structure, the inner panel 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com