Combined continuous rolling and continuous drawing machine with three sets of double-roller rolling machine and seven die drawing machines

A technology of rolling mill and wire drawing machine, which is applied in the field of continuous rolling and continuous drawing machine combined with 3 sets of twin-roll rolling mill and 7-die wire drawing machine, which can solve the problems of inability to continue processing, high cost, coarse crystal lattice, etc., and achieve less energy, crystal The lattice structure is more uniform and the lattice structure is uniform and fine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

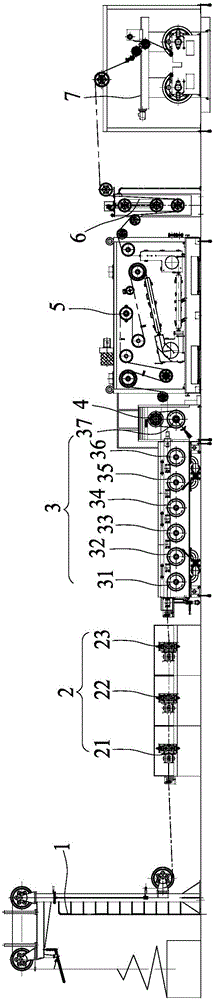

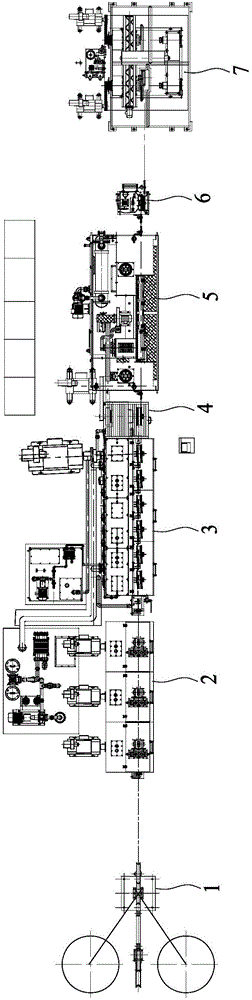

[0024] Such as figure 1 and figure 2 As shown, the present invention discloses 3 sets of two-roll rolling mills and 7-die wire drawing machines combined continuous rolling and continuous drawing machine, including rod release device 1, 3 sets of twin-roll mills 2, 7-die wire drawing machine 3, fixed speed wheel 4, and annealing device 5. The wire storage wheel set 6 and the wire take-up device 7.

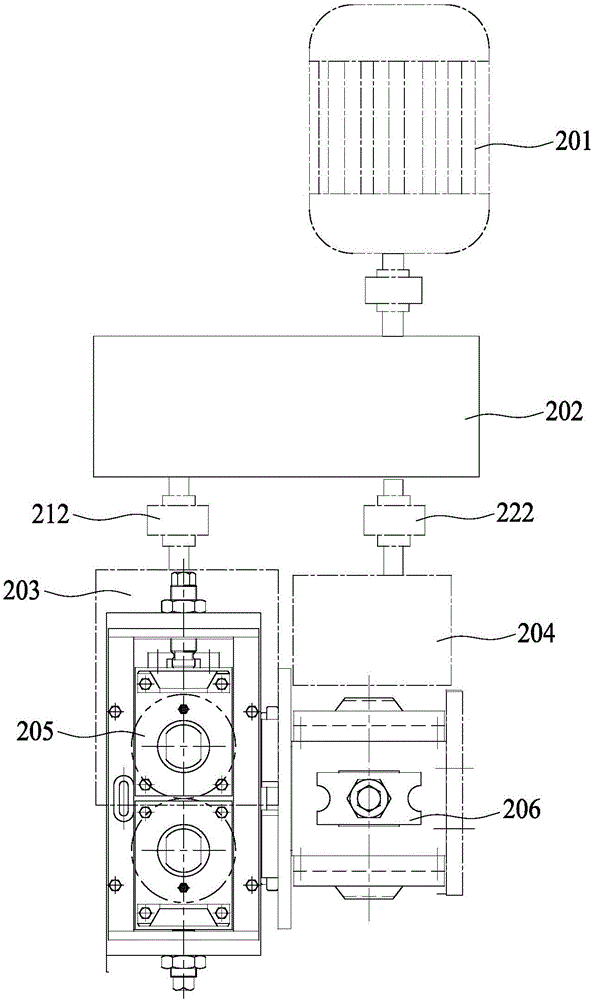

[0025] In the unit of the present invention, the rod-releasing device 1, the fixed speed wheel 4, the annealing device 5, the wire storage wheel group 6 and the wire take-up device 7 can be the same as the existing common 13-mode large drawing machine. The rear 7 of the 7-die wire drawing machine 3 of the present invention is exactly the same as the common 13-die drawing machine. The 3 groups of two-roll mills 2 are composed of 3 groups of independent rolling mills 31 , 32 and 33 .

[0026] The rod releasing device 1 has a copper rod inlet and a copper rod outlet. The copper rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com