An electric reciprocating cutting device

A cutting device and reciprocating technology, which is applied in metal processing and other directions, can solve the problems of depending on the operator for effect control, deviation of pruning consistency, and uneven hair length, etc., so as to improve fluency, reduce interference, and have good functional integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

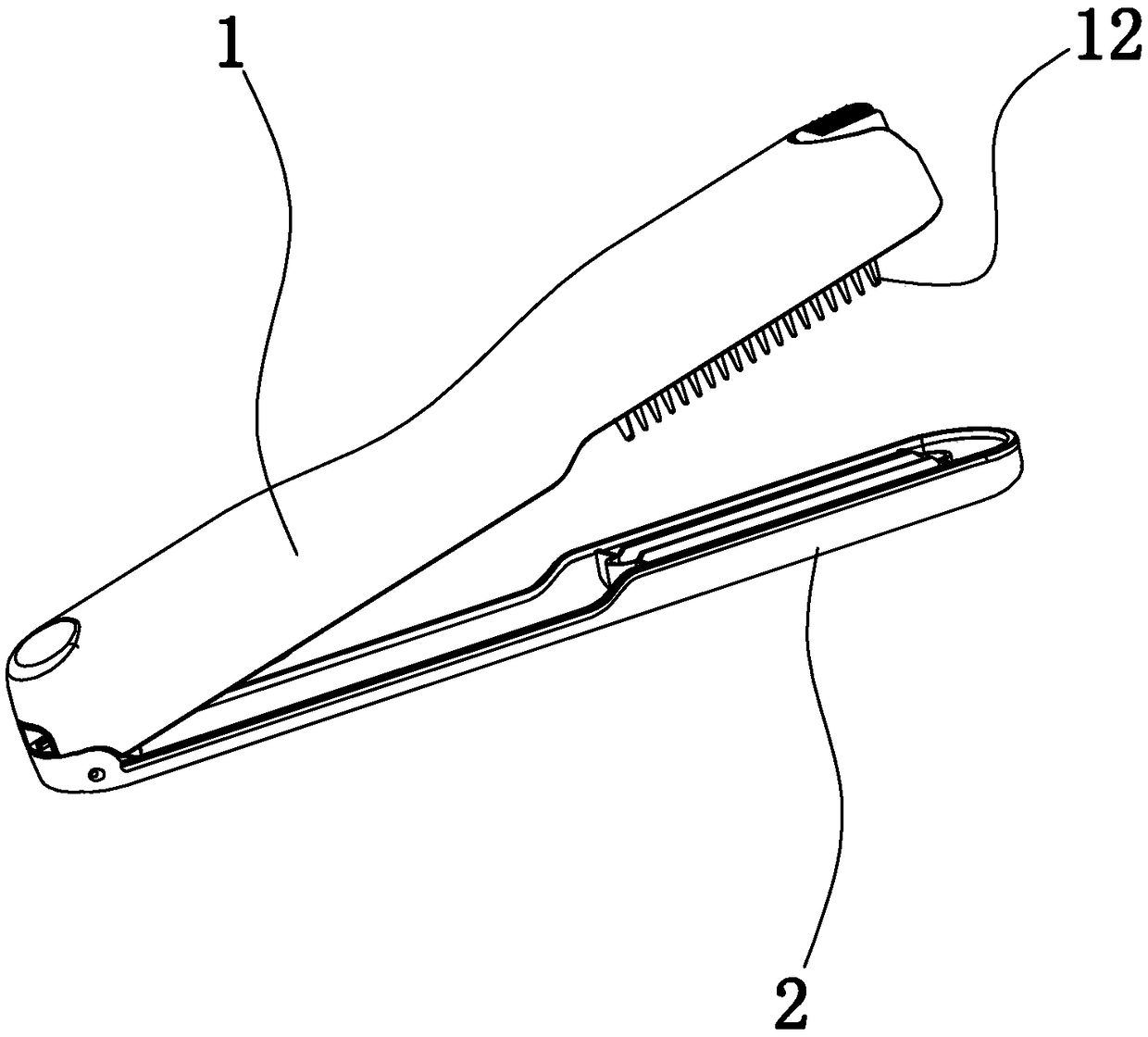

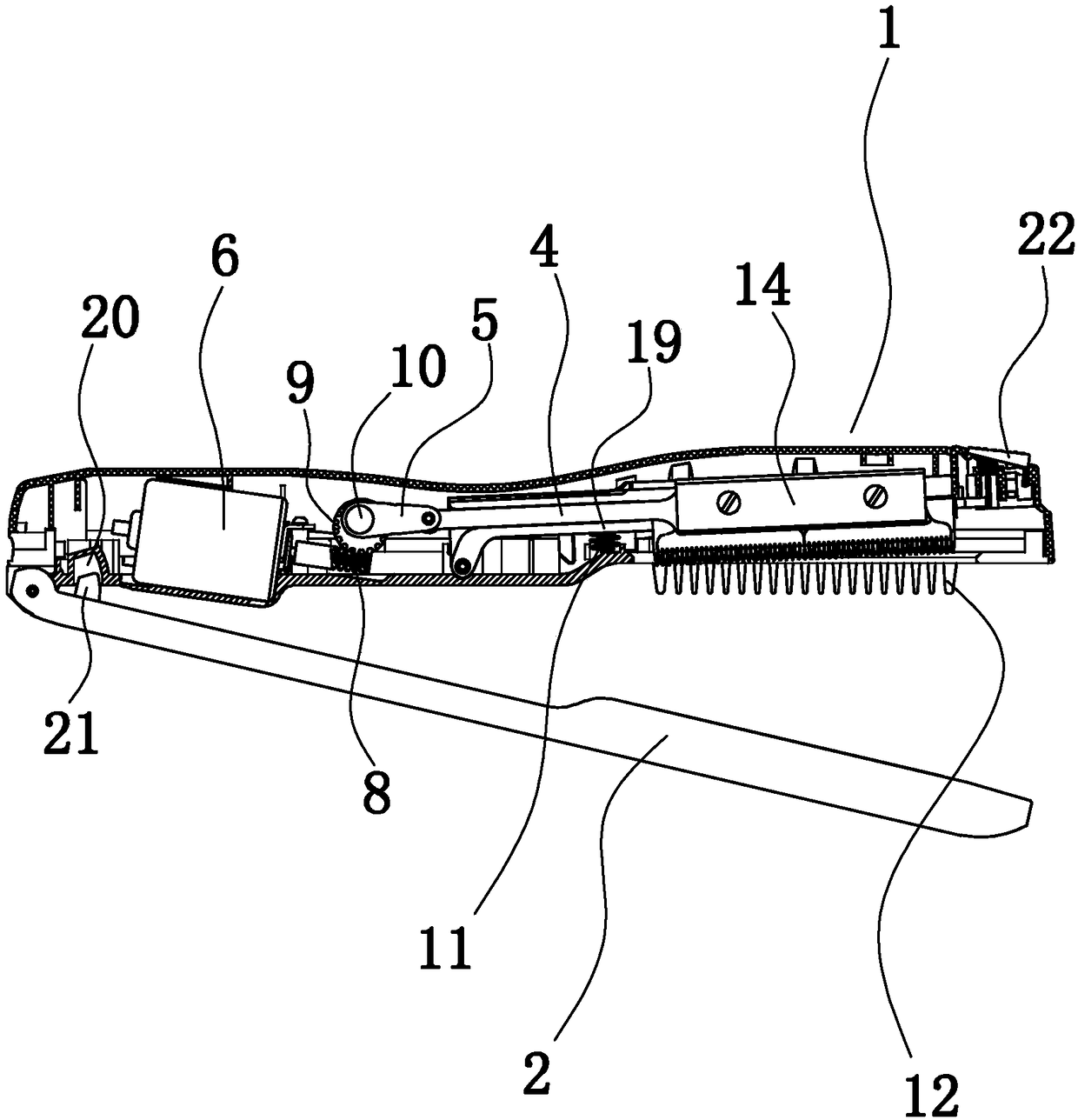

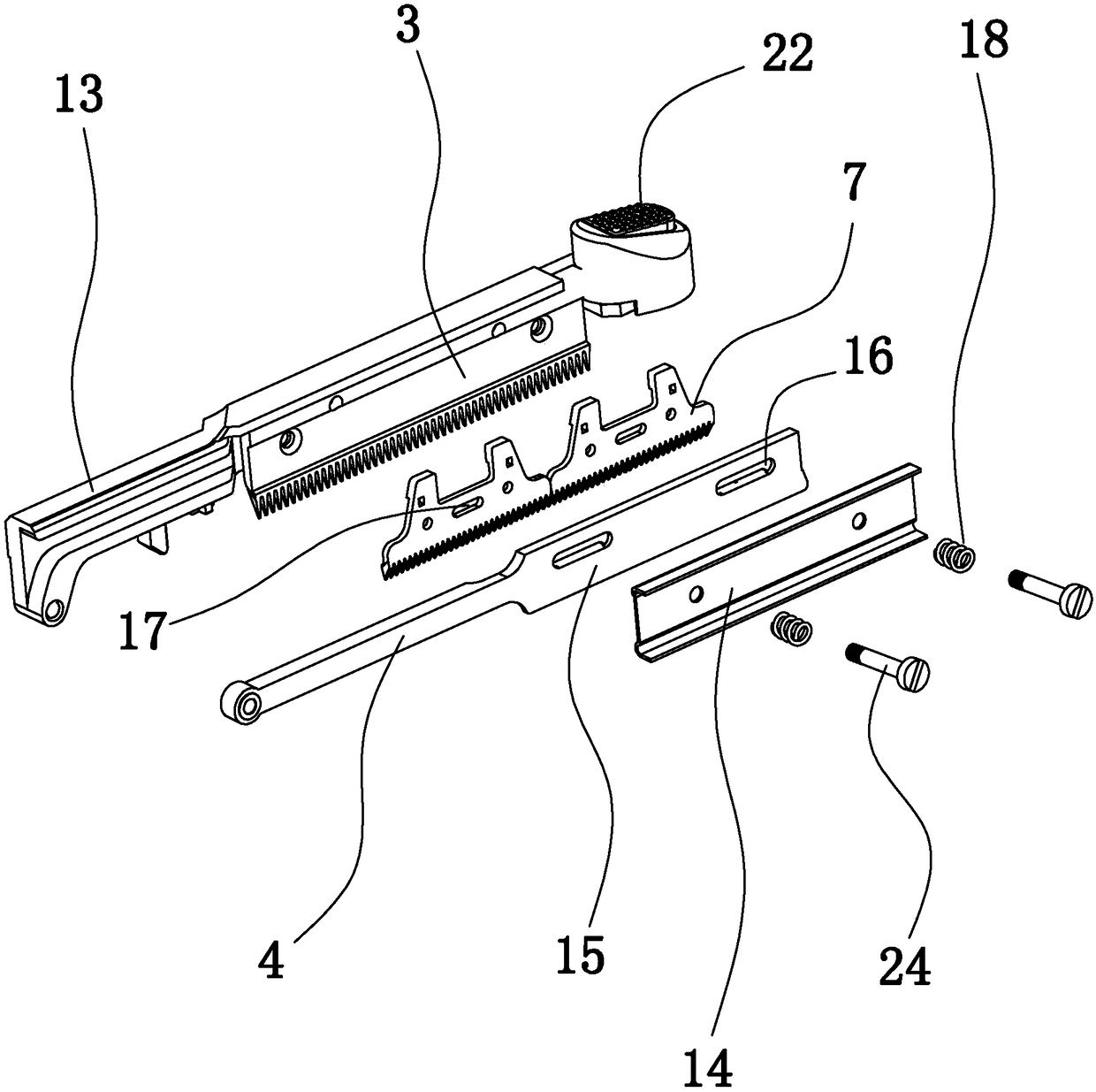

[0024] Embodiment 1: as Figure 1 to Figure 5 In the shown embodiment, an electric reciprocating cutting device includes a main casing 1 and a plywood bar 2 below the main casing. There is a return spring for pushing the plywood bar and the main shell apart. The main shell is equipped with a fixed blade 3, a pull rod 4, a transmission rod 5, a motor 6, and a movable blade that can move up and down relative to the fixed blade to make a cutting action. 7. The worm 8 connected to the output shaft of the motor, the worm wheel 9 matched with the worm, the eccentric shaft 10 arranged on the worm gear and the top spring 11 used to push the connecting rod upward. The shaft is rotationally connected with the worm wheel, the movable blade is connected with a pull rod, one end of the pull rod is hinged with one end of the transmission rod, and the other end of the transmission rod is connected with the eccentric shaft.

[0025] The main housing is provided with at least one comb 12, the...

Embodiment 2

[0028] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 6 to Figure 7 As shown in , the main housing is provided with a push rod 25 slidably connected with the main housing and a crushing cylinder 26 fixed with the main housing. The slidable direction of the push rod is the up and down direction. Connecting rod 27, be provided with the crushing piston 28 that cooperates with the sliding seal of crushing cylinder in the crushing cylinder, the slidable direction of the crushing piston is the up and down direction, and the crushing piston is provided with a piston rod 29, the piston rod is arranged vertically and The piston rod is above the crushing piston, the lower end of the piston rod is connected to the crushing piston, the upper end of the piston rod is connected to the horizontal connecting rod, the upper end of the push rod is connected to the horizontal connecting rod, and the crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com