Double planet row hybrid system and hybrid vehicle

A technology of hybrid power system and dual planetary row, which is applied in the direction of hybrid vehicles, motor vehicles, power plants, etc., can solve the problems of large number of control elements, low system efficiency, and complex structure, so as to increase output power and improve transmission efficiency , the effect of reducing volume and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

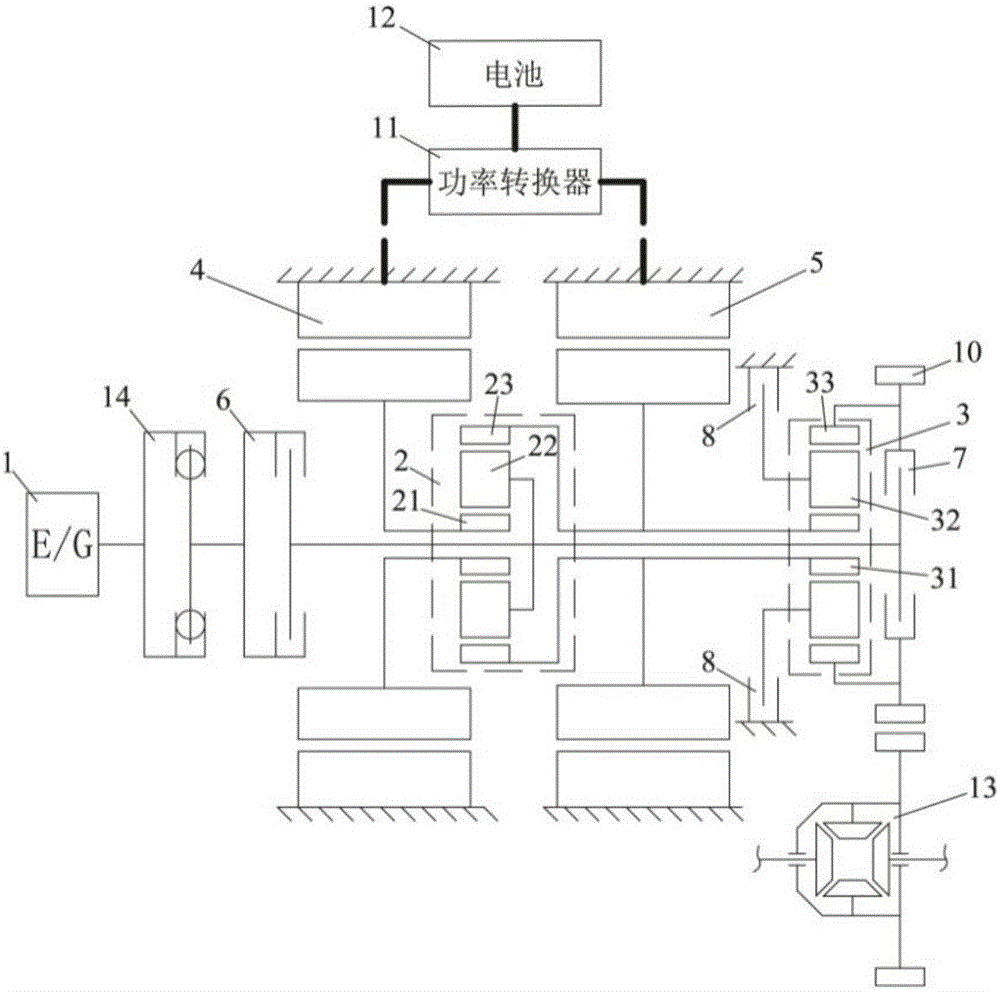

[0025] Such as figure 1As shown, a dual planetary row hybrid power system of an embodiment of the present invention is schematically shown, which includes an engine 1, a first planetary gear set 2, a second planetary gear set 3, a first motor 4, a second motor 5, Output member 10; wherein, the first planetary gear set 2 is provided with a first sun gear 21, a first planet carrier 22 and a first ring gear 23, and the second planetary gear set 3 is provided with a second sun gear 31 and a second planet carrier 32 and the second ring gear 33; the first sun gear 21 is set to rotate together with the rotor of the first motor 4, and the first ring gear 23 and the second sun gear 31 are set to rotate together with the rotor of the second motor 5 ; the second ring gear 33 is arranged to rotate together with the output member 10 (such as an output gear, an output shaft, etc.); and, the first torque transmission member 6, the second torque transmission member 7 and the braking member 8;...

Embodiment 2

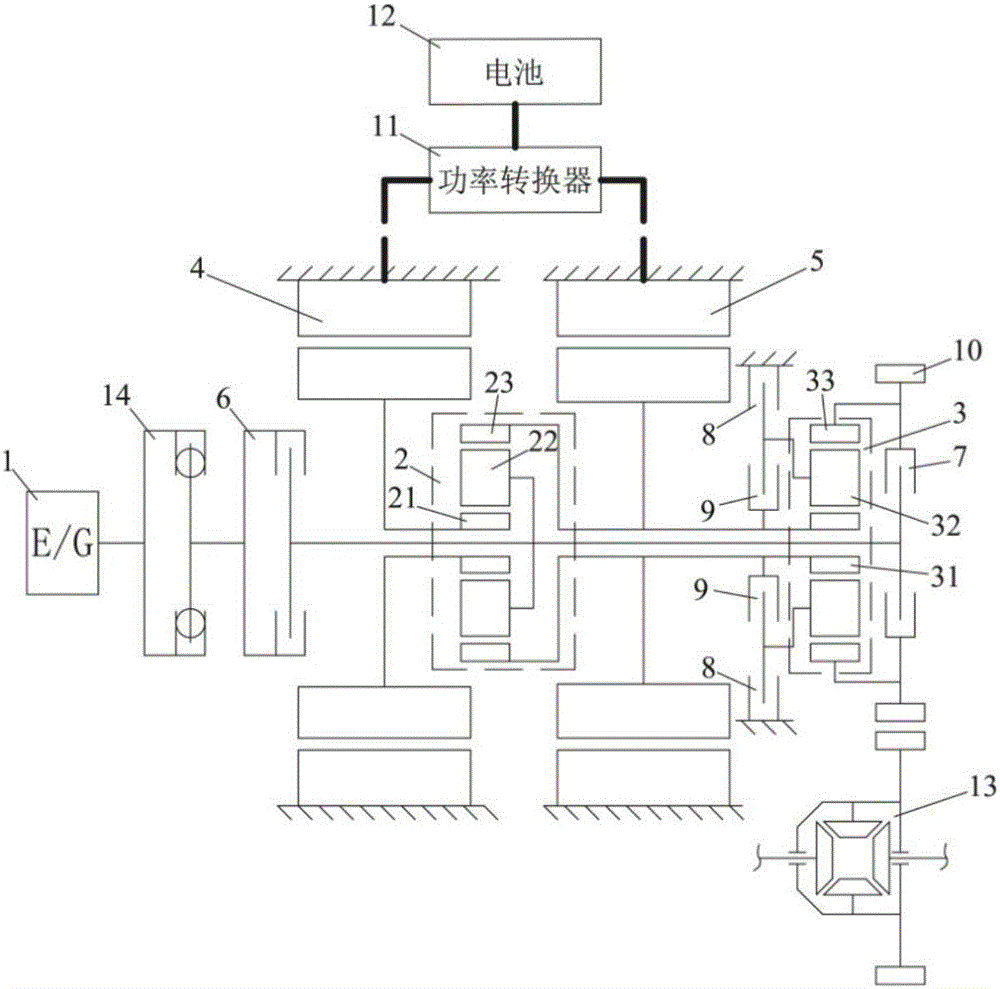

[0036] Such as figure 2 As shown, it schematically shows a dual-planetary-row hybrid power system according to another embodiment of the present invention. The structure of the double-planetary-row hybrid power system in this embodiment is roughly the same as that of the double-planetary-row hybrid power system in Embodiment 1. The difference is that the dual planetary row hybrid power system of this embodiment also includes a third torque transmission member 9, which can be selectively combined to securely connect the second planet carrier 32 and the second sun gear 31 Keep circumferentially stationary together; thus, on the basis of the driving modes that can be realized in Embodiment 1, more driving modes can be realized, increasing the power output mode of the double planetary row hybrid power system of the embodiment of the present invention richness.

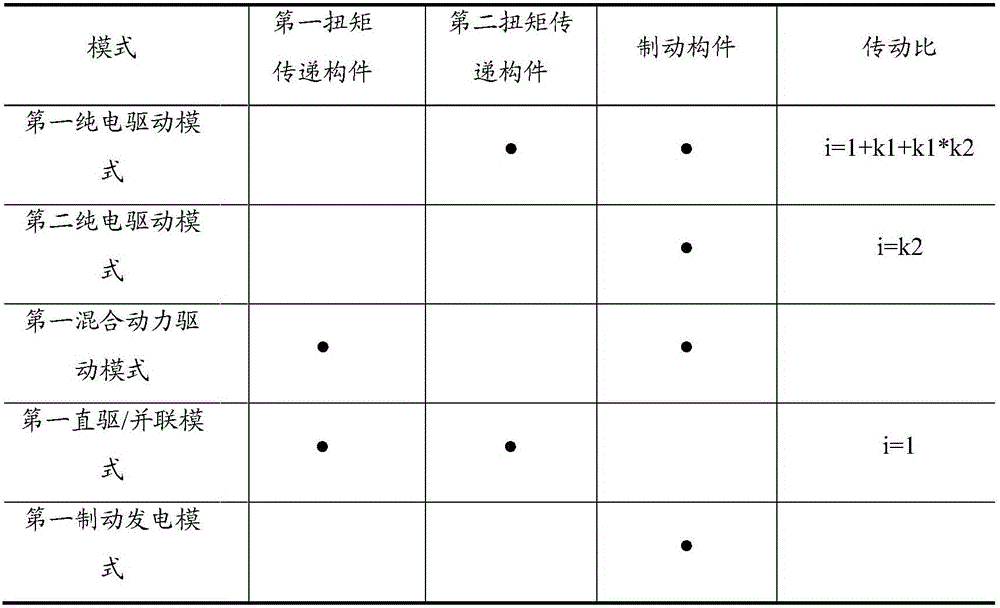

[0037] As shown in Table 2, the operation logic of the double planetary hybrid power system according to the embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com