An electric adjustable jack

An adjustable jack technology, applied in the direction of lifting devices, etc., can solve the problems of economic waste, limited jack lifting capacity, and the need to purchase additionally, and achieve the effect of reducing torque demand, reducing torque demand, and increasing lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation and use of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention. In the description, the structural positions of various components, such as directions such as upper, lower, top, and bottom, are not absolute, but relative. These directional representations are appropriate when the various components are arranged as shown in the figures, but when the positions of the various components in the figures are changed, the directional representations also change accordingly.

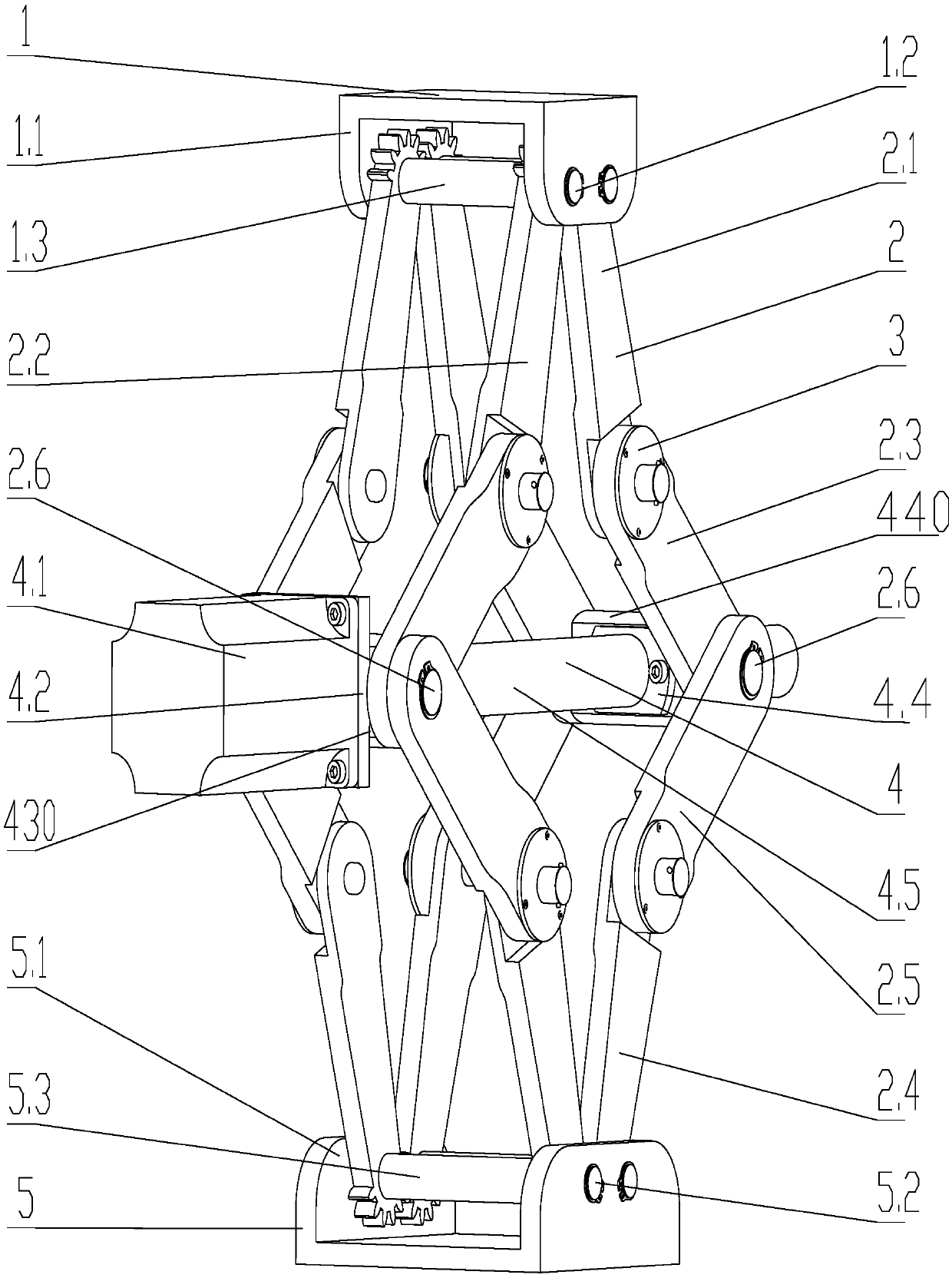

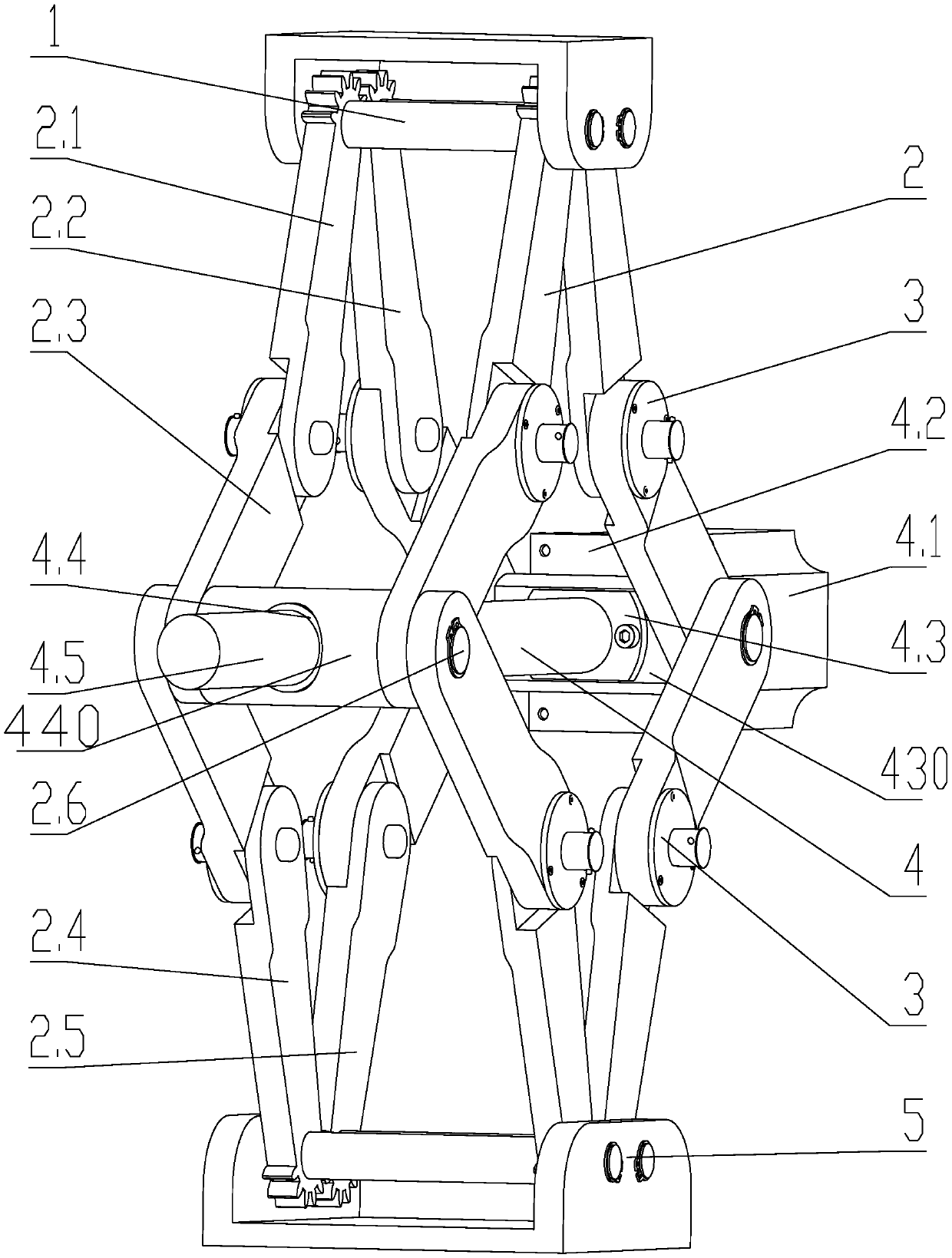

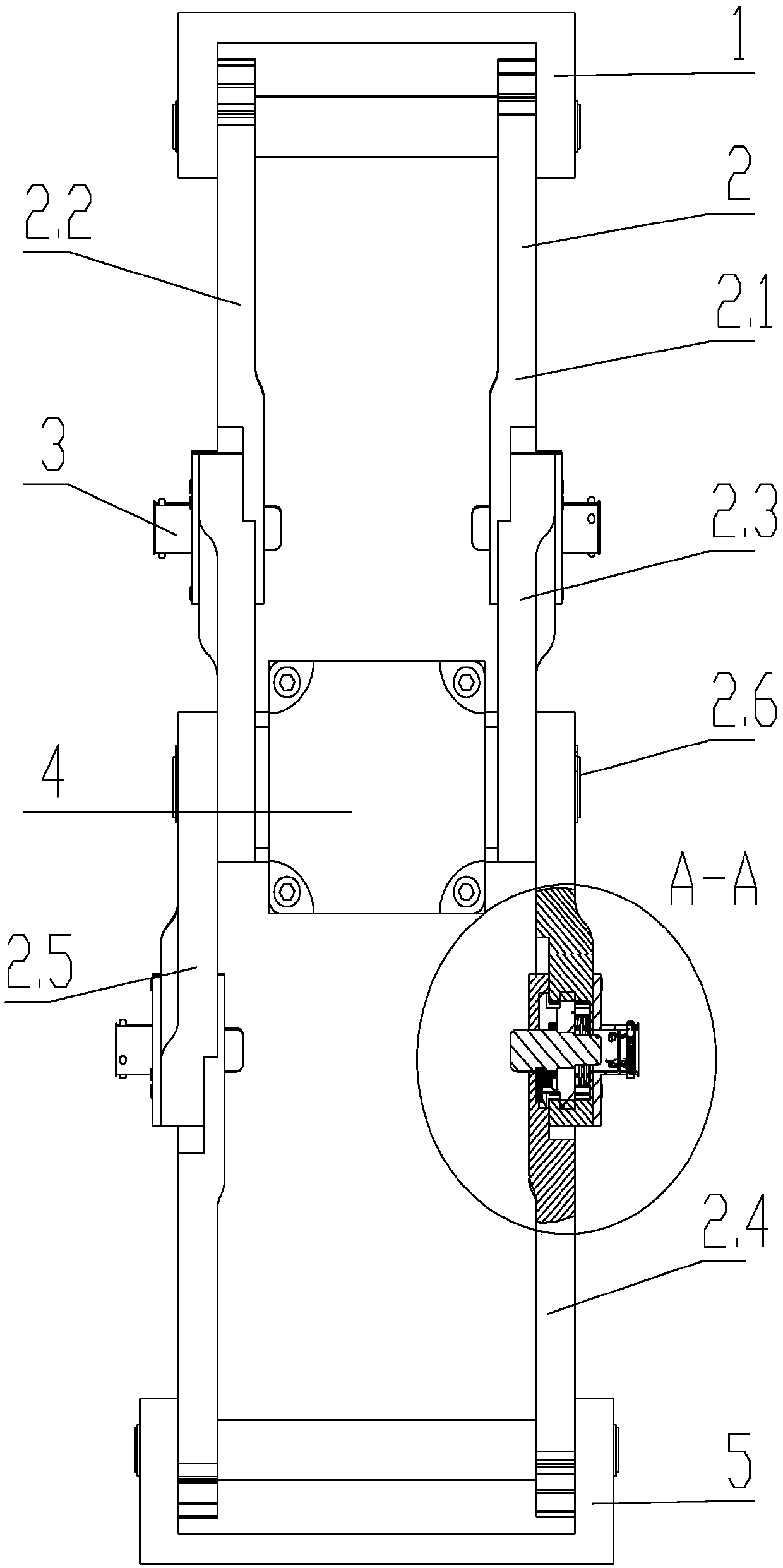

[0031] like Figure 1-2 As shown, an electric scissor jack with adjustable bearing range, its structure includes: a jack assembly 1 , a lifting assembly 2 , an automatic locking assembly 3 , a power transmission assembly 4 , and a base assembly 5 .

[0032] like figure 1 As shown, the plug assembly 1 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com