Device and method for preparing 1,1,1,2-tetrafluoroethane

A technology of tetrafluoroethane and tubular reactors, which is applied to the preparation of halogenated hydrocarbons, halogen substitution preparations, chemical instruments and methods, etc., can solve the problems of complex reactor structure, increased reactor vibration, and large tube vibration. Achieve the effects of improving operational stability and operational flexibility, long operating cycle, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

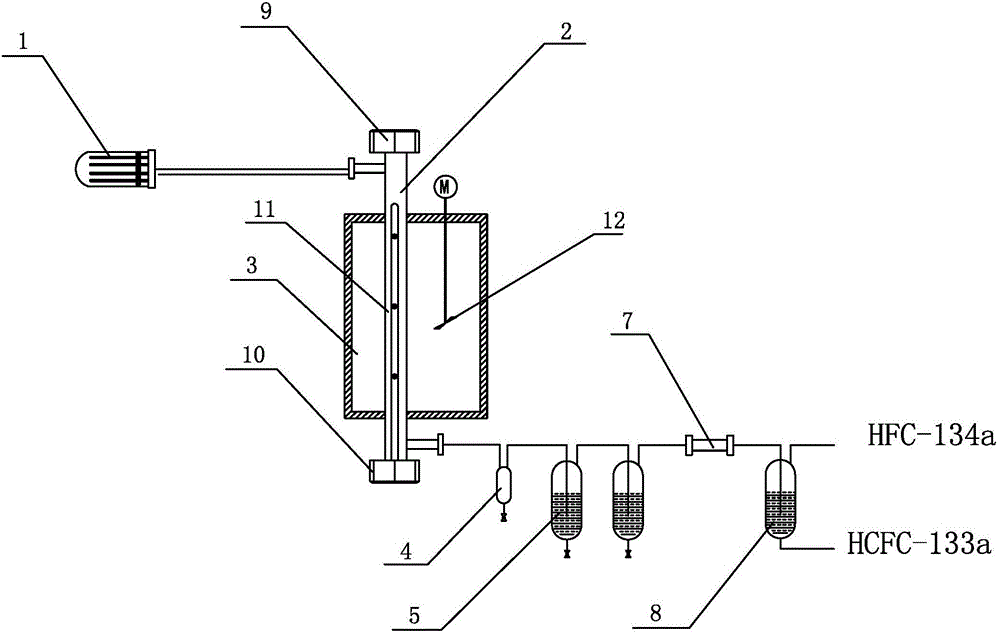

[0023] A device for preparing 1,1,1,2-tetrafluoroethane, including a preheater 1, a vertically installed tubular reactor 2, a molten salt furnace 3 (material is 316L), a buffer tank 4, a water washing tower 5, Alkali washing tower 6, drying tower 7, rectifying tower 8, preheater 1, tubular reactor 2, buffer tank 4, water washing tower 5, alkali washing tower 6, drying tower 7, and rectifying tower 8 are connected in sequence, and the tubular reaction The reactor 2 includes a reactor body 11 (the length-to-diameter ratio is 20:1, the nominal diameter is 35mm, and the material is 316L) and an upper head 9 and a lower head 10 arranged at both ends of the reactor body 11, and the reactor body 11 passes through Molten salt furnace 3.

[0024] When the device is used for the preparation of 1,1,1,2-tetrafluoroethane, the molten salt filled in the molten salt furnace 3 is potassium nitrate and sodium nitrate with a mass ratio of 1:1, and 120ml is filled in the reactor body 11 Fluorin...

Embodiment 2

[0026] A device for preparing 1,1,1,2-tetrafluoroethane, including a preheater 1, a vertically installed tubular reactor 2, a molten salt furnace 3 (made of Monel alloy), a buffer tank 4, and a water washing tower 5. Alkali washing tower 6, drying tower 7, rectifying tower 8, preheater 1, tubular reactor 2, buffer tank 4, water washing tower 5, alkali washing tower 6, drying tower 7, rectifying tower 8 are connected in sequence, The tubular reactor 2 includes a reactor body 11 (a length-to-diameter ratio of 15:1, a nominal diameter of 40mm, and a material of Monel alloy) and an upper head 9 and a lower head 10 arranged at both ends of the reactor body 11. The reactor The body 11 passes through the molten salt furnace 3 .

[0027]When the device is used to prepare 1,1,1,2-tetrafluoroethane, the molten salt filled in the molten salt furnace 3 is potassium nitrate and sodium nitrate with a mass ratio of 1:2, and the reactor body 11 is filled with 120ml Fluorination catalyst (the...

Embodiment 3

[0029] A device for preparing 1,1,1,2-tetrafluoroethane, including a preheater 1, a vertically installed tubular reactor 2, a molten salt furnace 3 (made of stainless steel 316L), a buffer tank 4, and a water washing tower 5 , alkali washing tower 6, drying tower 7, rectifying tower 8, preheater 1, tubular reactor 2, buffer tank 4, water washing tower 5, alkali washing tower 6, drying tower 7, rectifying tower 8 are connected in turn, tubular The reactor 2 includes a reactor body 11 (the ratio of length to diameter is 10:1, the nominal diameter is 45mm, and the material is stainless steel 316L), and the upper head 9 and the lower head 10 arranged at both ends of the reactor body 11, the reactor body 11 Go through the molten salt furnace3.

[0030] When the device is used to prepare 1,1,1,2-tetrafluoroethane, the molten salt filled in the molten salt furnace 3 is potassium nitrate and sodium nitrate with a mass ratio of 2:1, and the reactor body 11 is filled with 120ml Fluorin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com