Four-door roller shaft structure

A technology of roller shafts and rollers, applied in the field of roller shafts, can solve the problems of affecting the production cycle, difficult to control maintenance time, and axial movement of rolling ball bearings, so as to eliminate the phenomenon of axial movement, reduce the difficulty of disassembly, and reduce the load bearing capacity. The effect of empowerment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

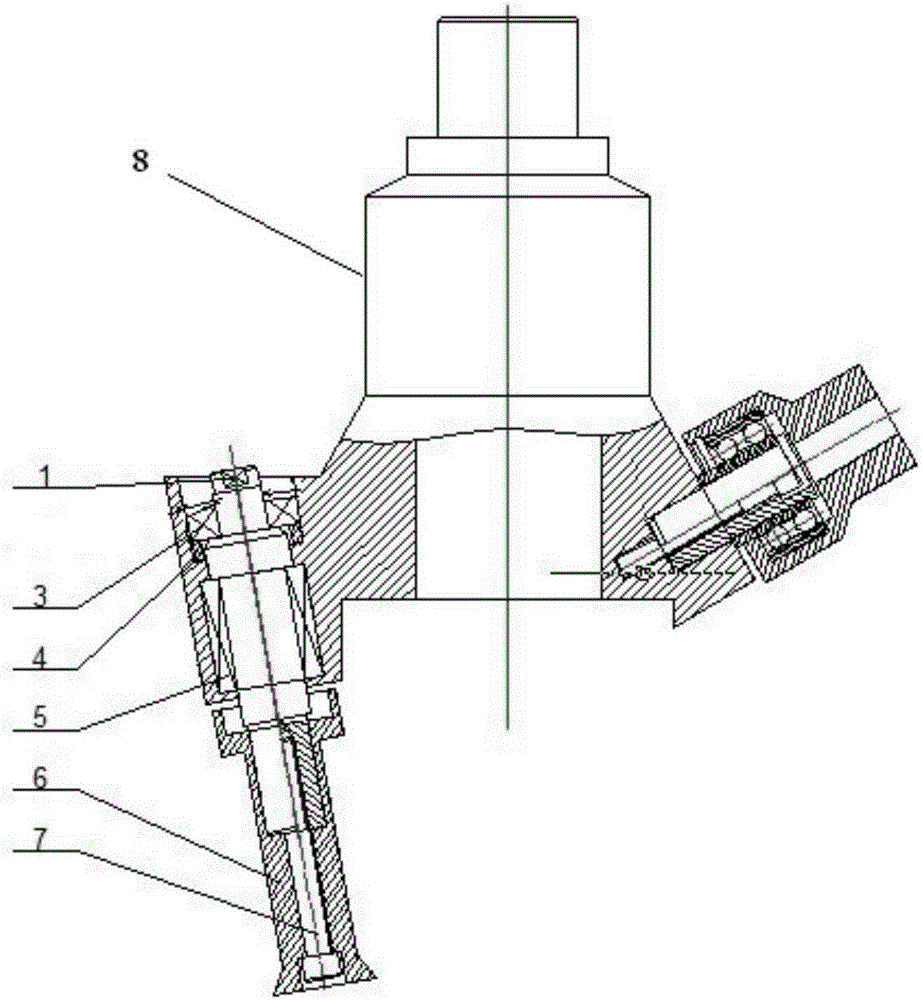

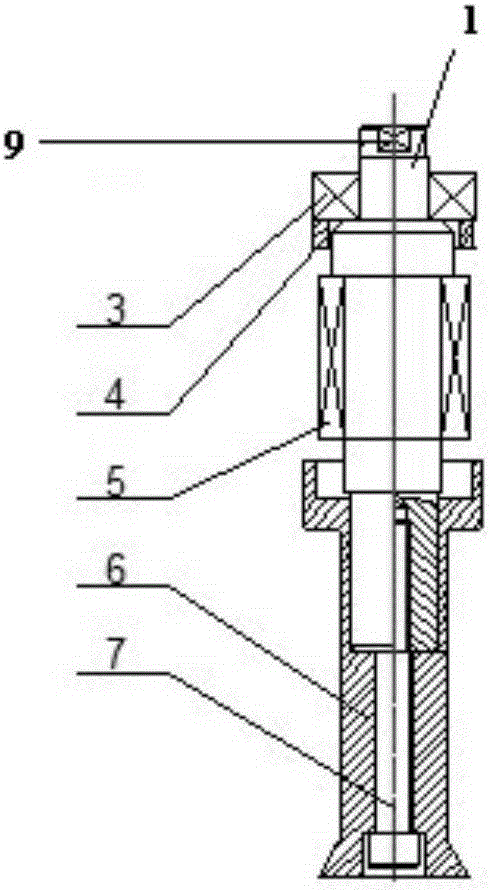

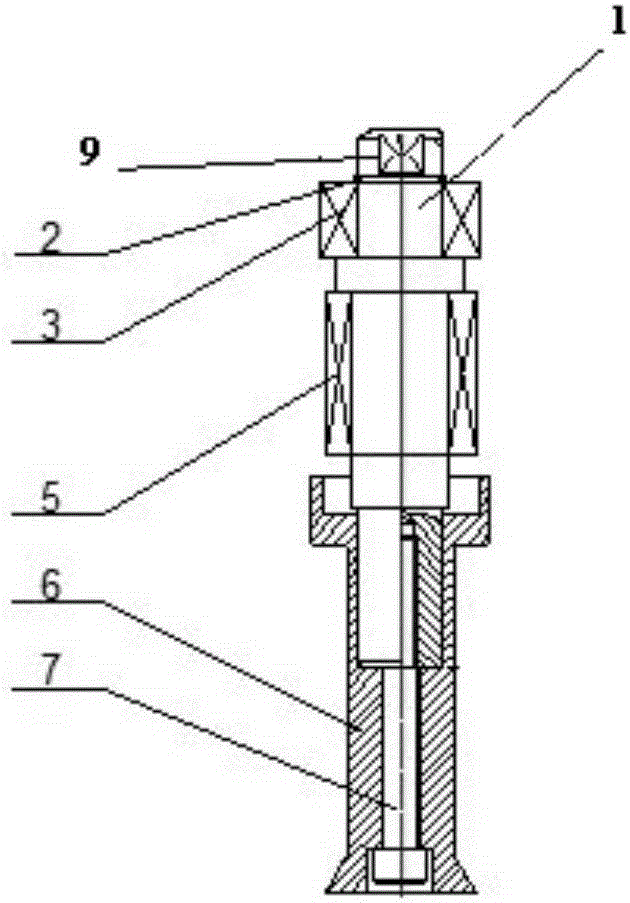

[0022] A kind of four-door roller shaft 1 structure, its structure is as image 3 As shown, the structure of the four-door roller shaft 1 is installed on the bracket 8, and the structure of the four-door roller shaft 1 includes a roller shaft 1. The end surface of the head of the roller shaft 1 is provided with a flat end 9, and the middle part of the roller shaft 1 is provided with a first Needle roller bearing 5, the roller shaft 1 is provided with a roller 6 at the end, and the roller shaft 1 is provided with a first threaded hole at the end, and the hexagonal bolt 7 matching the first threaded hole is penetrated from the side of the roller 6, and the roller shaft is 1 is fixed on the tail of the roller shaft 1, the head of the roller shaft 1 is provided with a second needle bearing 11, and the flat end 9 is provided with two second threaded holes, and the shaft diameter of the head of the roller shaft 1 is the second needle bearing 11. 1 / 2 of the shaft diameter of the bear...

Embodiment 2

[0025] A four-door roller shaft 1 structure, the four-door roller shaft 1 structure is installed on the bracket 8, the four-door roller shaft 1 structure includes a roller shaft 1, the end surface of the head of the roller shaft 1 is provided with a flat end 9, the roller shaft 1 is provided with a first needle roller bearing 5 in the middle, a roller 6 is provided at the tail of the roller shaft 1, and a first threaded hole is provided at the tail of the roller shaft 1. Penetrate, fix the roller shaft 1 on the tail of the roller shaft 1, the head of the roller shaft 1 is provided with a second needle bearing 11, and the flat end 9 is provided with a second threaded hole, the shaft diameter of the head of the roller shaft 1 It is 3 / 5 of the shaft diameter of the second needle roller bearing 11, and one end of the second needle roller bearing 11 is provided with an axial stop ring 2 to prevent its axial movement.

[0026] When the roller 6 is worn, the screw that matches the se...

Embodiment 3

[0028] A four-door roller shaft 1 structure, the four-door roller shaft 1 structure is installed on the bracket 8, the four-door roller shaft 1 structure includes a roller shaft 1, the end surface of the head of the roller shaft 1 is provided with a flat end 9, the roller shaft 1 is provided with a first needle roller bearing 5 in the middle, a roller 6 is provided at the tail of the roller shaft 1, and a first threaded hole is provided at the tail of the roller shaft 1. Penetrate, and fix the roller shaft 1 on the tail of the roller shaft 1. The head of the roller shaft 1 is provided with a second needle bearing 11, and the flat end 9 is provided with three second threaded holes. The shaft diameter of the head of the roller shaft 1 is It is 11 / 20 of the shaft diameter of the second needle bearing 11, and one end of the second needle bearing 11 is provided with an axial retaining ring 2 to prevent its axial movement.

[0029] When the roller 6 is worn, the screw that matches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com