Leather shrinkage temperature testing device

A shrinkage temperature and testing device technology, which is applied in the field of leather physical parameter testing, can solve problems such as poor sensitivity of Hall sensors, uneven heating medium temperature, and the accuracy of leather shrinkage temperature test data cannot meet the requirements, so as to improve the accuracy , Good consistency, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

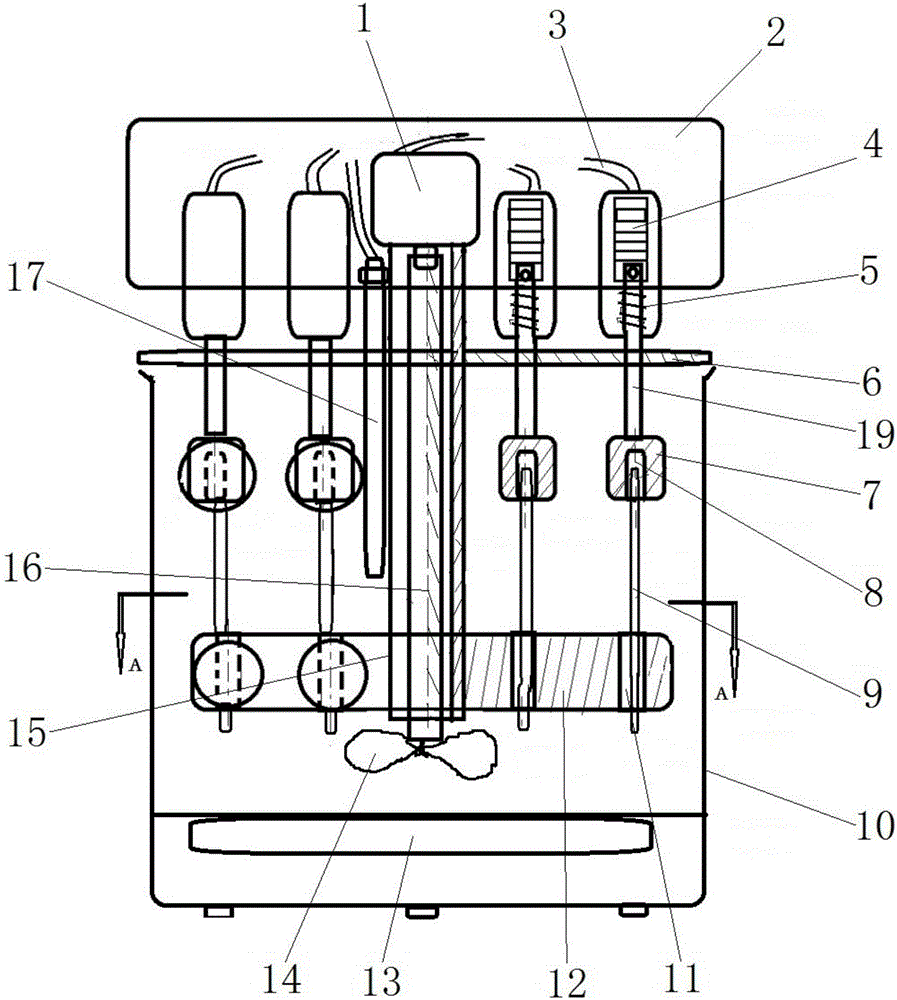

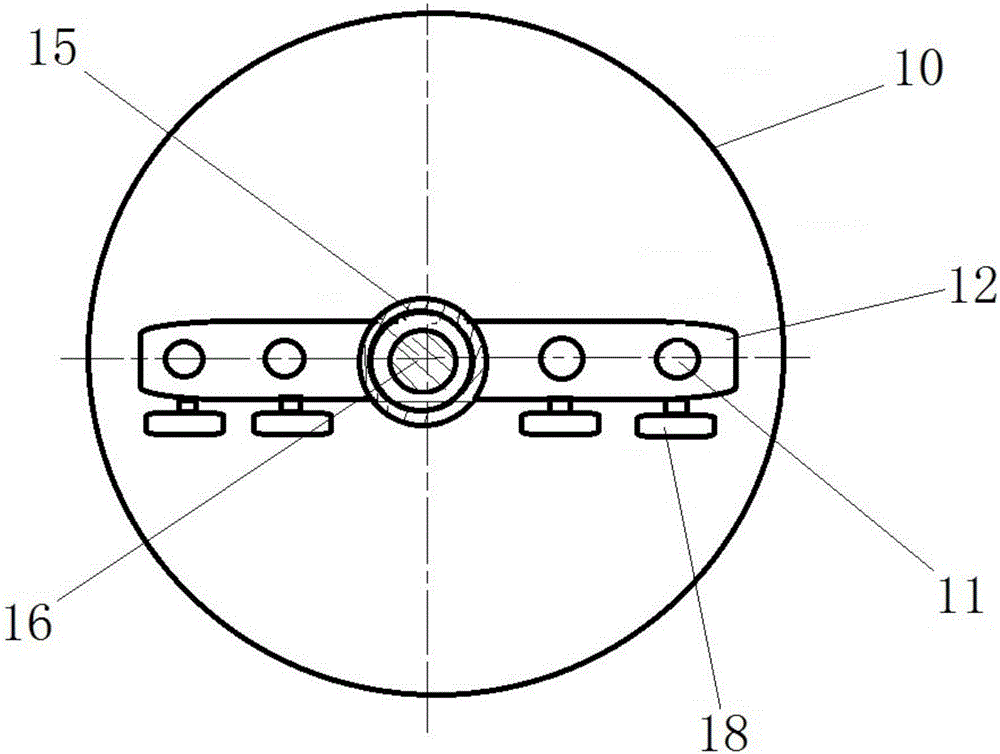

[0026] The invention provides a leather shrinkage temperature testing device, such as figure 1 As shown, the detection box 2 is included, the middle part of the detection box 2 is provided with a motor 1, the motor 1 is connected with the drive shaft 16, and the end of the drive shaft 16 is connected with a stirring paddle 14, and the stirring paddle 14 extends into the front of the detection box 2. The bottom of the electric heating cup 10 arranged below, wherein the outside of the drive shaft 16 is also covered with a column 15, a bearing is arranged between the drive shaft 16 and the column 15, the drive shaft 16 can rotate relative to the inner wall of the column 15, and at the same time drive the stirring paddle The blade 14 rotates; the detection box 2 is also provided with a capacitance sensor 4, there are multiple capacitance sensors 4, and the capacitance sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com