A fuel cell metal bipolar plate assembly with enhanced fluid uniformity

A metal bipolar plate and fuel cell technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of fuel cell mass power density that is difficult to further improve, uneven concentration distribution, and increase the weight of bipolar plates. Achieve the effects of novel structural design, compensation concentration reduction, and pressure loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

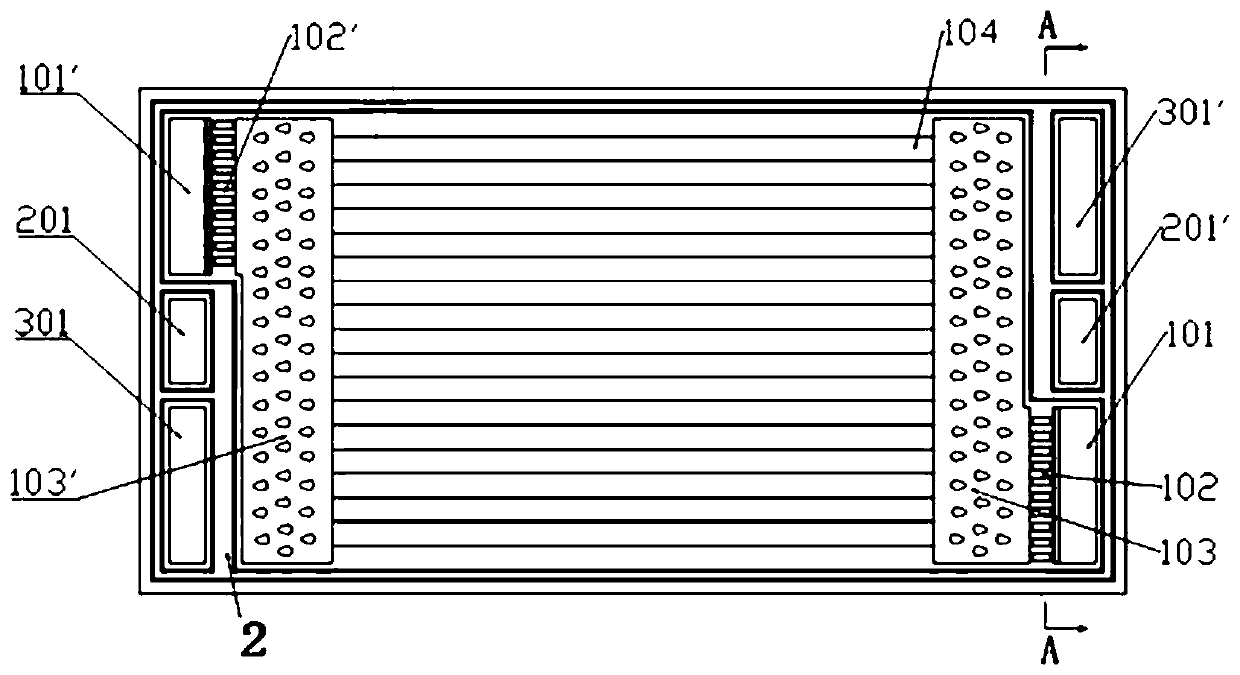

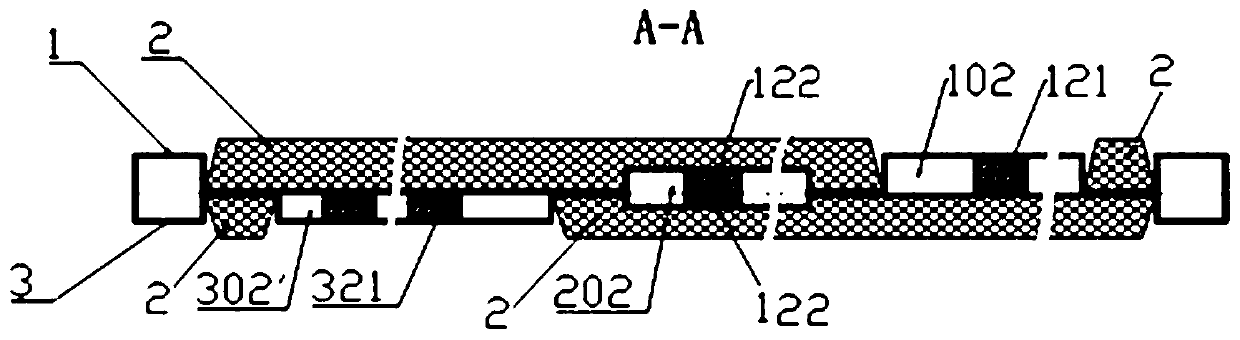

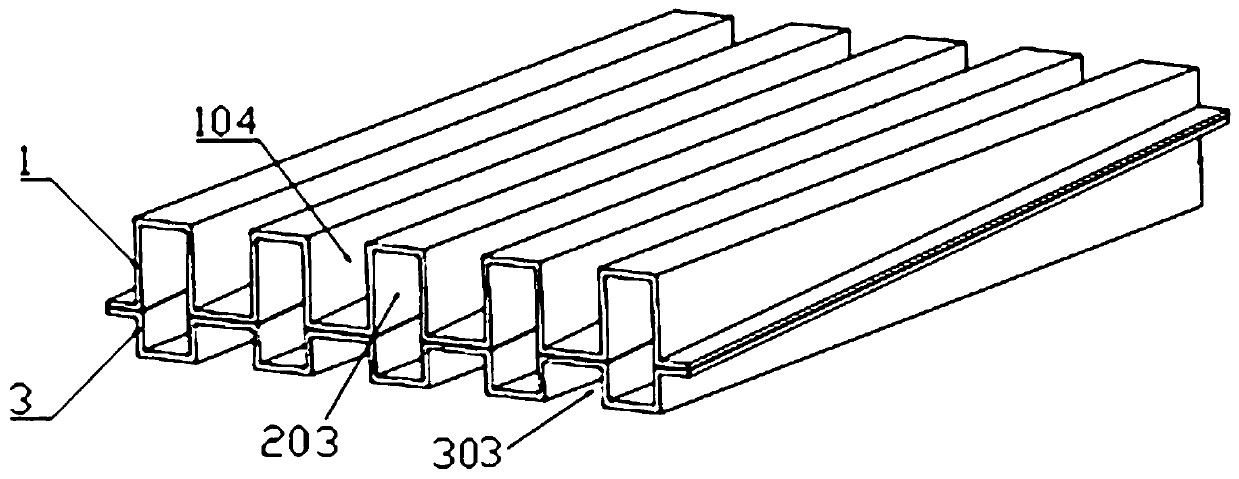

[0042] like Figure 1-5 As shown, a fuel cell metal bipolar plate assembly that enhances fluid uniformity includes a cathode single plate 1, an anode single plate 3, and a seal 2 assembled on the outside of the cathode single plate 1 and the anode single plate 3, respectively. The cavity between the anode single plate 3 and the cathode single plate 1 forms a coolant flow field, and the outer sides of the cathode single plate 1 and the anode single plate 3 respectively form a cathode flow field and an anode flow field. The cathode veneer 1 and the anode veneer 3 are obtained by stamping, punching and trimming a stainless steel sheet with a thickness of 0.1 mm. The cathode veneer 1 and the anode veneer 3 are identical and can be manufactured by the same mold. After the two single plates are assembled and bonded, they are laser welded to form a bipolar plate.

[0043] Among them, the cathode flow field includes a cathode inlet main pipeline 101, a cathode inlet direct connectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com