Wood carbonization process and its produced building materials

A technology of wood and carbonization, applied in wood heat treatment, charcoal/combustion, removal of solid waste, etc., can solve problems such as difficult control, lack of consistency, waste and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0084] Exemplary process #1

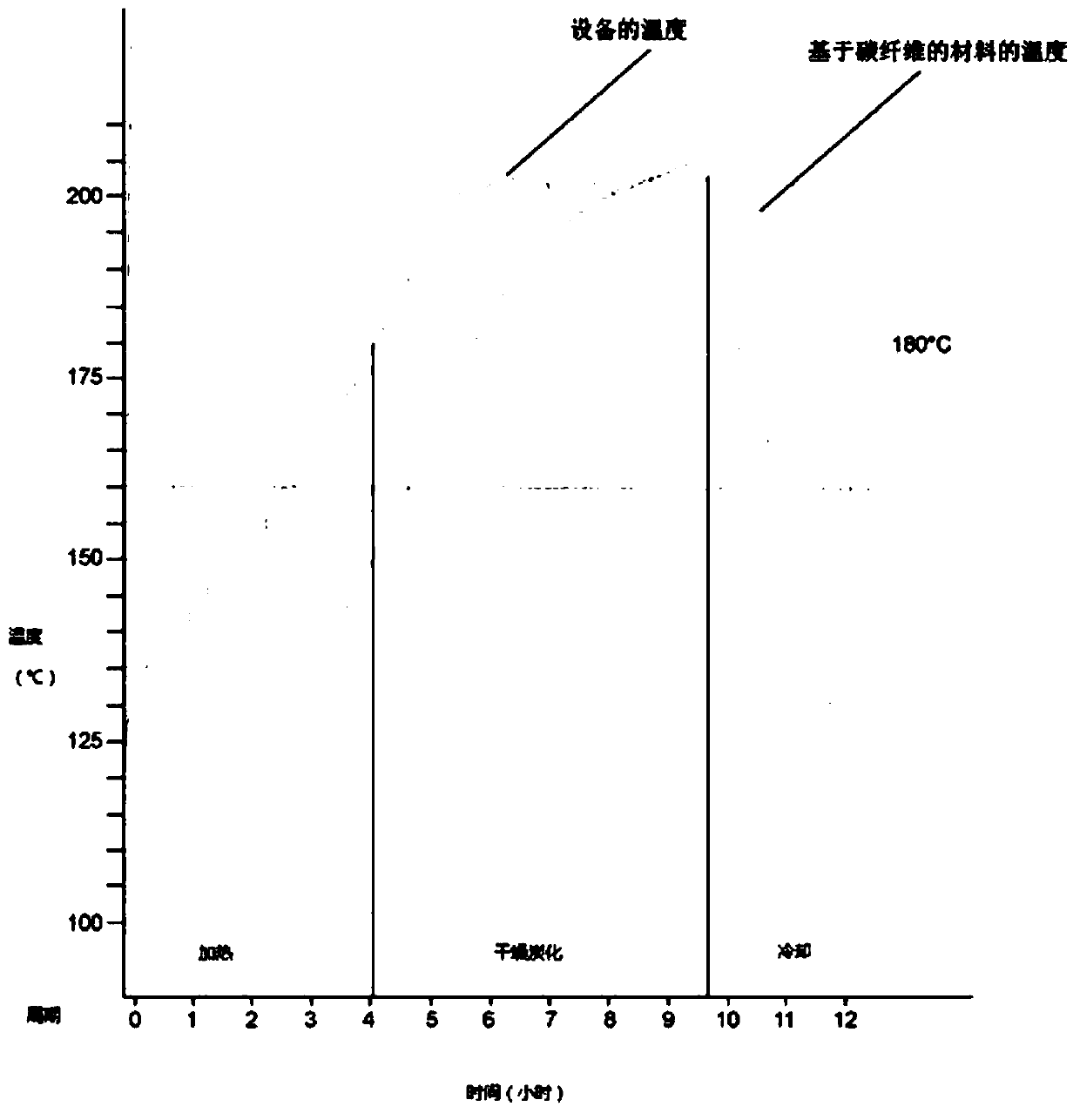

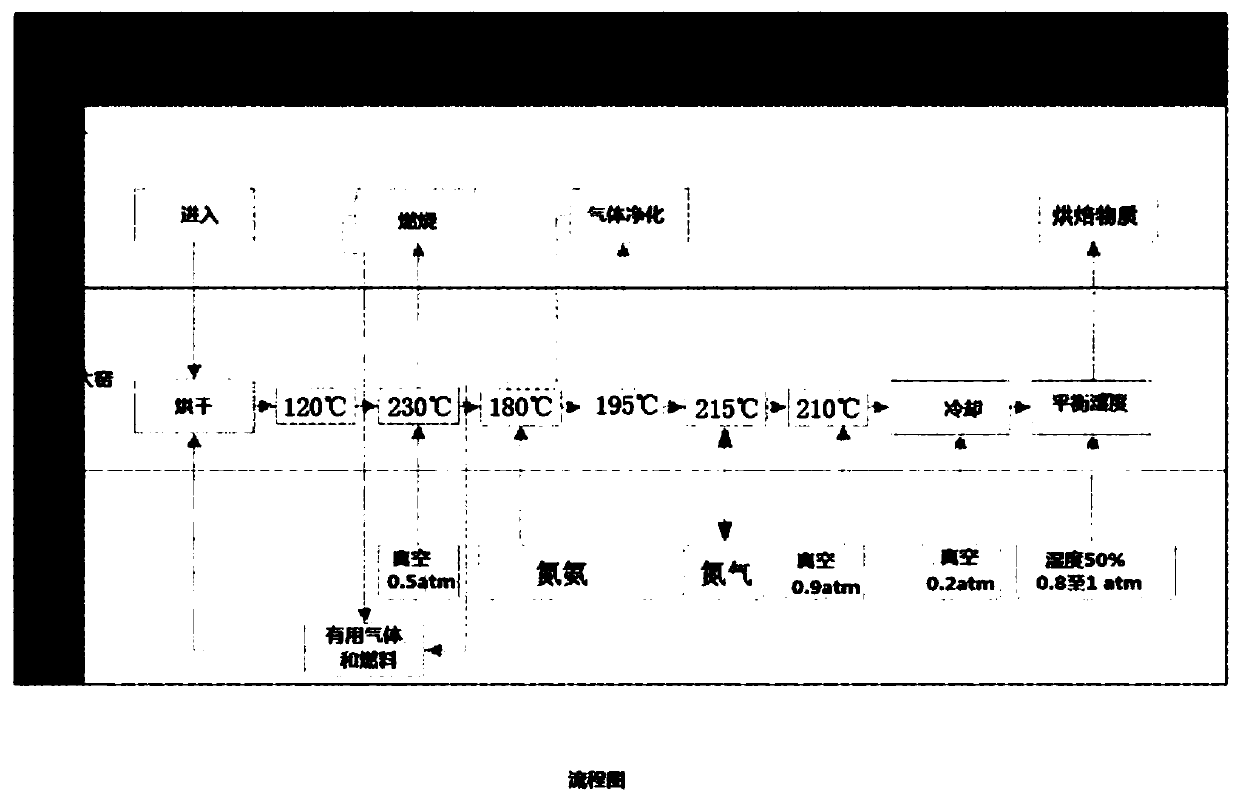

[0085] According to one embodiment, the method of the present invention is a temperature and time cycle for controlling the decomposition of natural organic polymers, in which the required building materials or element characteristics are given to them, such as the moisture of each layer of the cellulose material Content, stability, durability, strength, toughness, weather resistance, coatability and bonding properties.

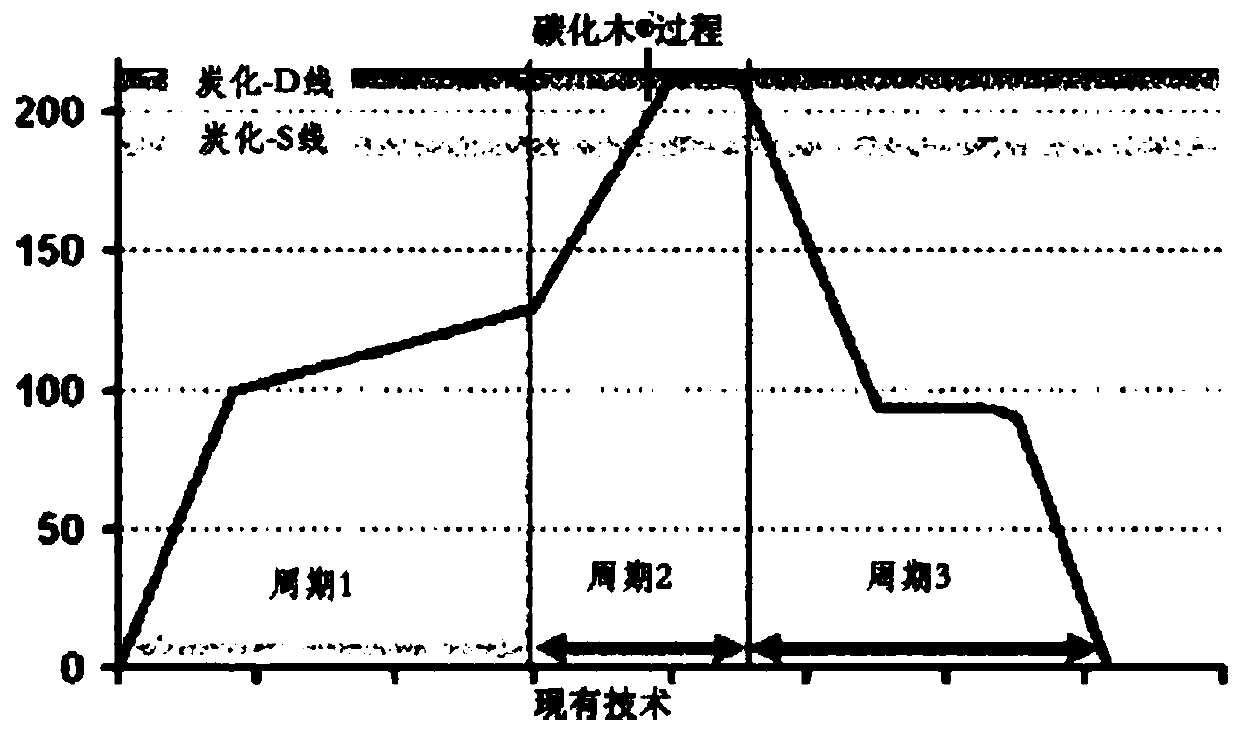

[0086] According to an embodiment of the present invention, the carbonization device cycles according to a specific temperature and time, and alternate gas or vacuum injection. For example, the following table describes a process that provides optimized structural material steps in a single device:

[0087]

[0088] Table 1-Example Process #1

example 2

[0090] Demonstration process #2

[0091] According to another embodiment, the method of the present invention may involve the following cycles in the carbonization unit:

[0092]

[0093] Table 2-Example Process #2

example 3

[0095] Exemplary process #3

[0096] According to another embodiment, the minimum necessary steps of the method of the present invention to process the cellulose-based material and the composition and structure of the appropriately modified material are:

[0097]

[0098] Table 3-Example Process #3

[0099] The other steps proposed in the present invention will define the desired characteristics of the wood according to the intended use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com