Process for wood torrefaction, and construction material produced therefrom

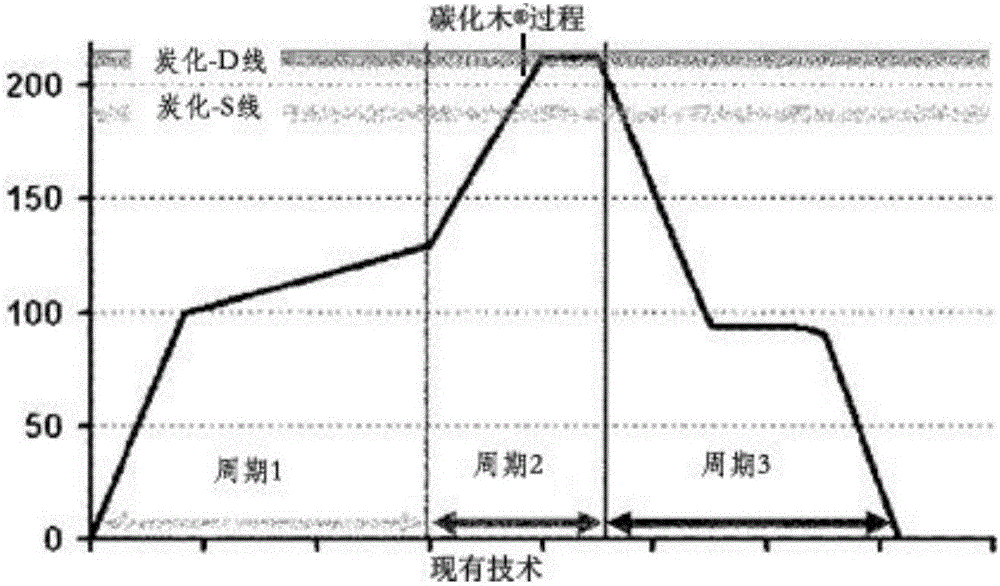

A carbonization and process technology, which is applied in the field of wood carbonization process and the building materials it produces, can solve the problems of waste and cost, difficulty in controlling the method, lack of consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0084] Exemplary Process #1

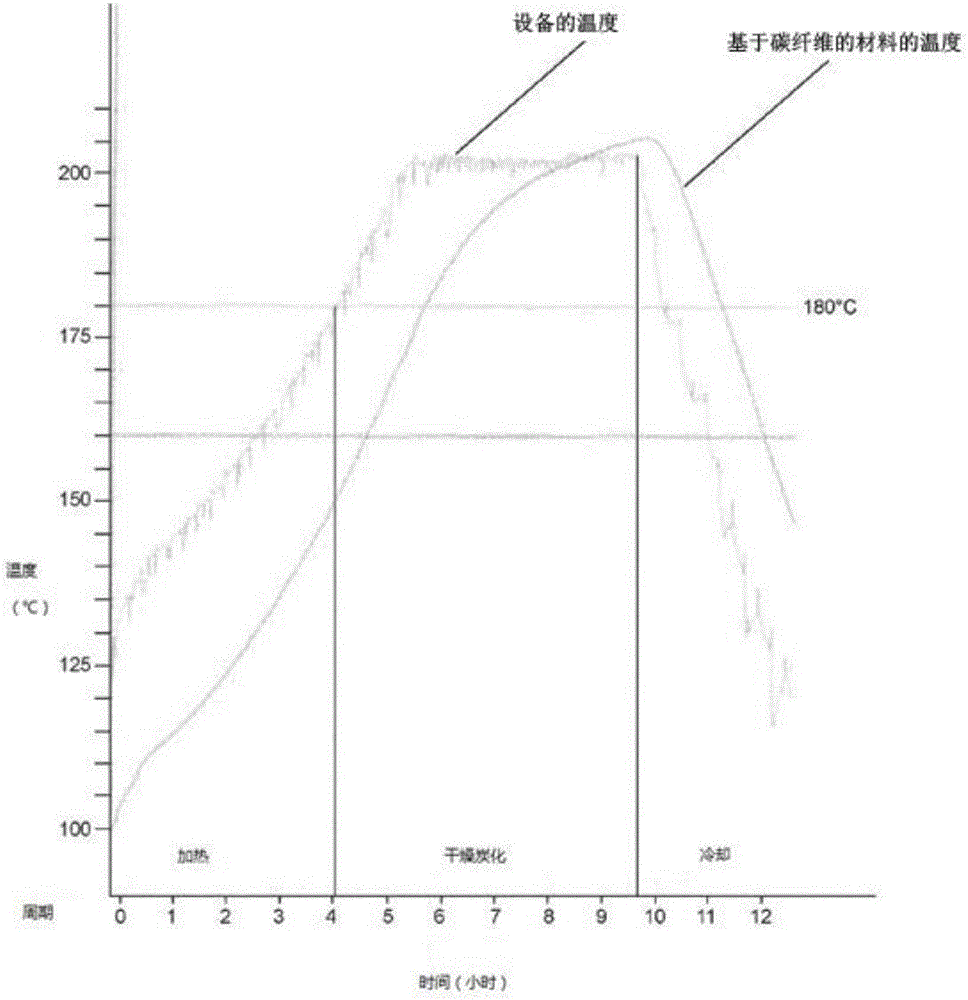

[0085] According to one embodiment, the method of the invention is a cycle of temperature and time for the controlled decomposition of natural organic polymers, in which the individual layers of the material such as cellulosic moisture are given the desired properties of the building material or element content, stability, durability, strength, toughness, weatherability, paintability and bonding properties.

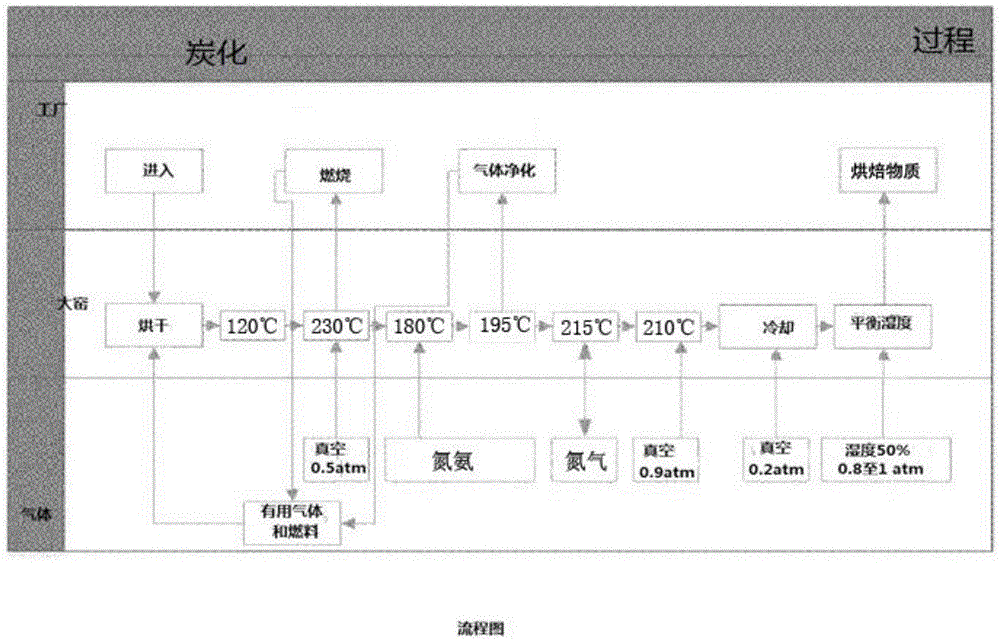

[0086] According to one embodiment of the present invention, the carbonization device is cycled according to a specific temperature and time, and alternately injected with gas or vacuum. For example, the table below describes a process that provides optimized structural material steps by implementing them in a single device:

[0087]

[0088] Table 1 - Example Process #1

example 2

[0090] Demonstration Process #2

[0091] According to another embodiment, the method of the invention may involve the following cycles in the carbonization plant:

[0092]

[0093] Table 2 - Example Process #2

example 3

[0095] Exemplary Process #3

[0096] According to another embodiment, the minimum necessary steps of the method of the present invention to process cellulose-based materials and appropriately modify the composition and structure of the materials are:

[0097]

[0098] Table 3 - Example Process #3

[0099] The other steps proposed in this invention will define the desired properties of the wood according to the intended use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com