Punching apparatus

A stamping device and stamping tool technology, applied in the direction of piercing presses, metal processing equipment, piercing tools, etc., can solve the problems of complex transmission mechanism, high size and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

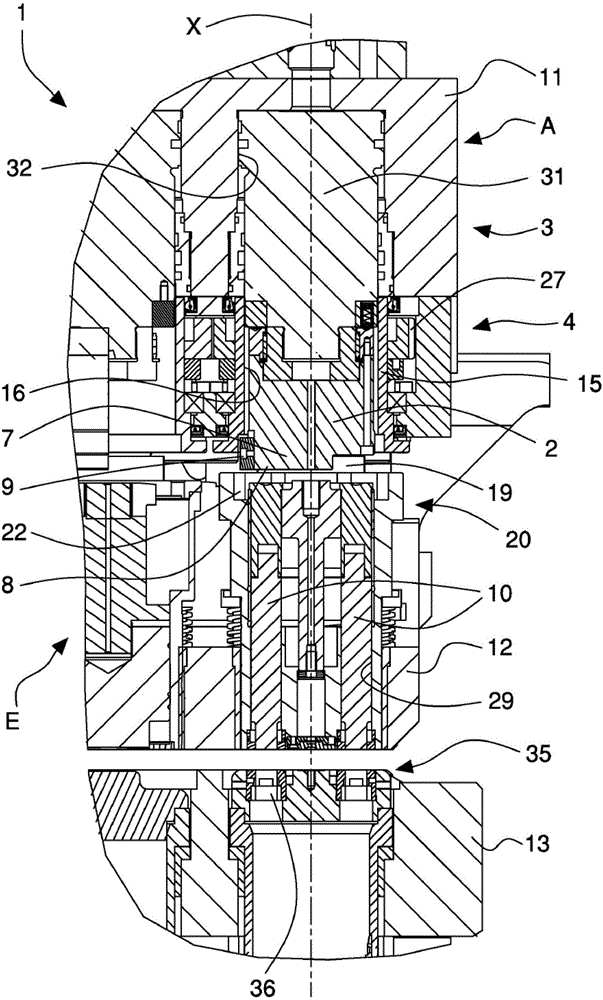

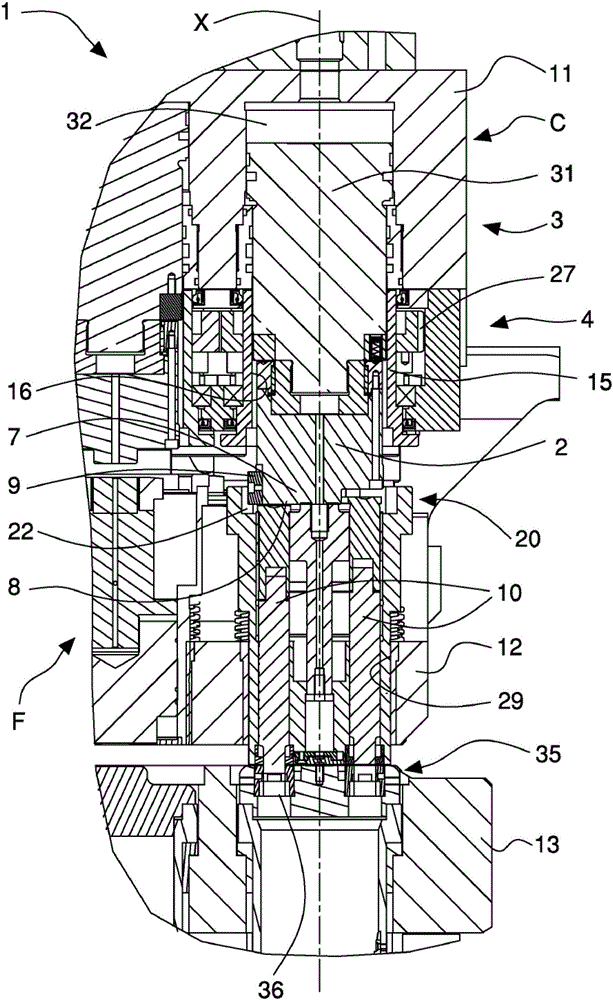

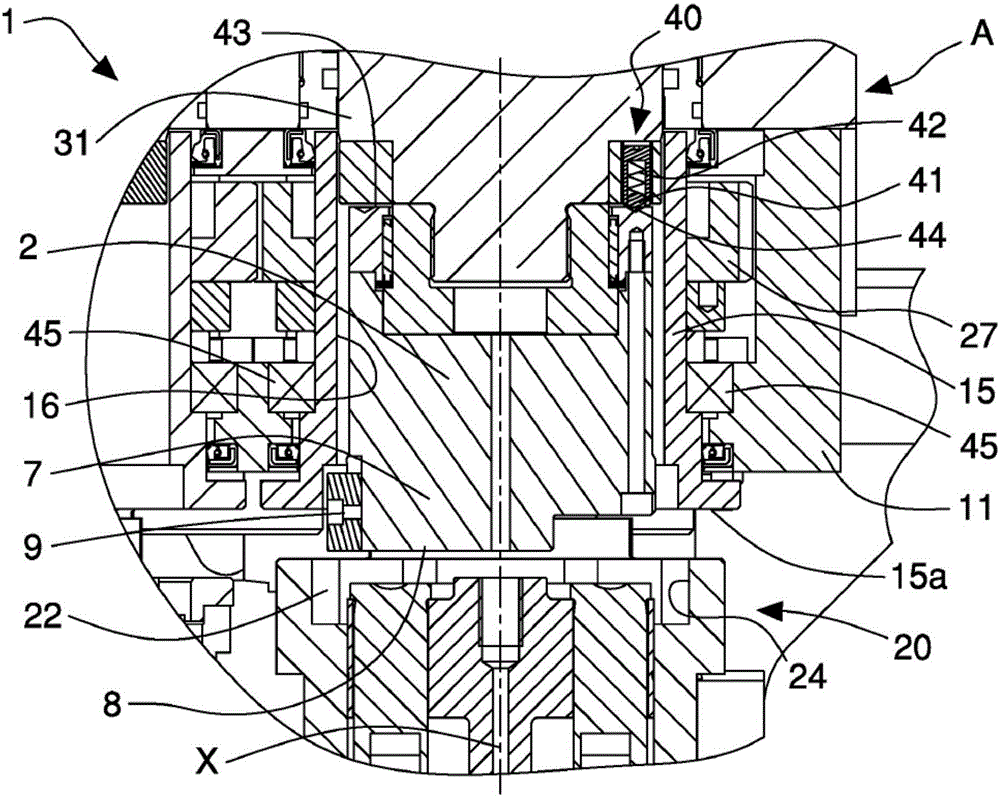

[0027] refer to Figure 1 to Figure 6 , shows a punching device 1 according to the invention, which may be associated with a punching machine tool of known type, not shown, arranged to perform cutting and / or punching on workpieces, in particular on sheet metal. / or stamping.

[0028] The stamping device 1 , usually also called a stamping head, comprises a tool holder 20 , a striking element 2 called a ram, a first drive mechanism 3 and a second drive mechanism 4 , wherein the tool holder 20 is provided with multiple a punching tool 10, the striking element 2 is adapted to interact with and selectively drive a set punching tool 10 (referred to as a punch), said first drive mechanism 3 for The striking element 2 is moved, and the second drive mechanism 4 is used to move the tool holder unit 20 .

[0029] The tool holder unit 20 generally comprises a drum, rotatable about a working axis X, and provided with a plurality of sockets 21 adapted to slidably receive a respective pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com