An electronic cigarette and its control method

A control method and technology for electronic cigarettes, applied in the field of electronic cigarettes, can solve problems such as liquid leakage, battery heating, mismatch of heating wire power, etc., and achieve the effects of stable temperature, simple structure, and reduced exploration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

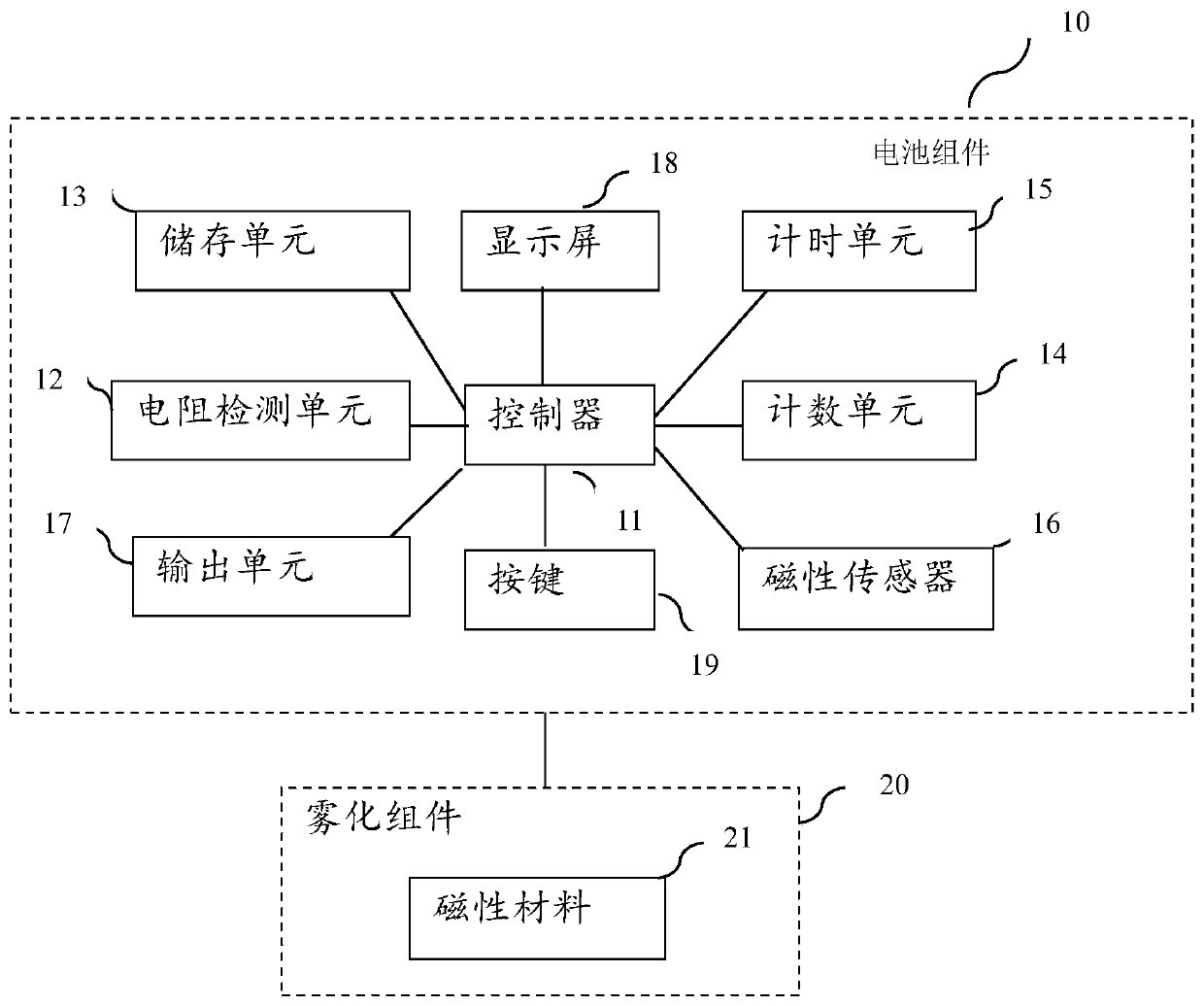

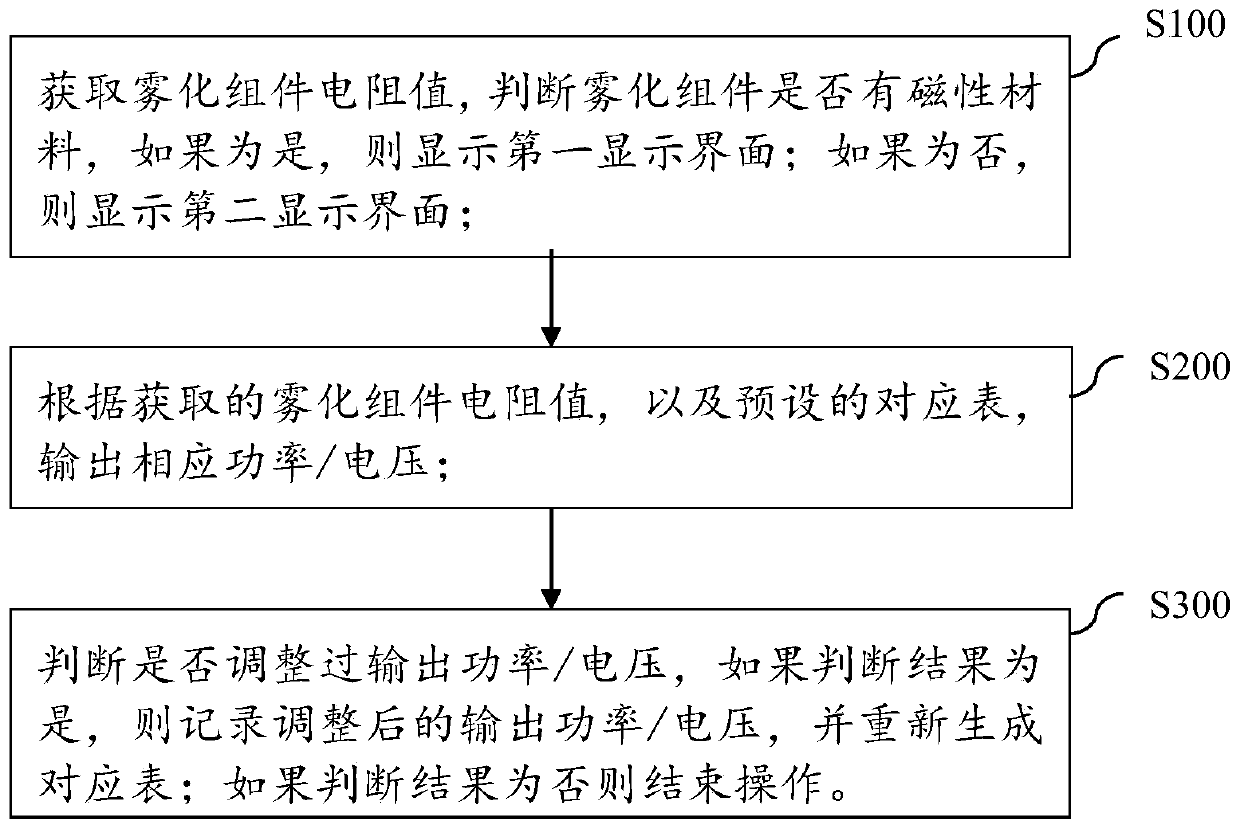

[0107] This embodiment is basically the same as Embodiment 1, except that in step A100 it is judged whether the atomization assembly 20 has a magnetic material 21, if yes, go to step A200, if no, don't go to step A200. In this way, when the magnetic material 21 is not detected, it can be switched to a common atomizer, that is, the power / voltage needs to be adjusted by itself, and there is no function of automatically adjusting the power / voltage according to the resistance value.

[0108] Specific steps are as follows:

[0109] Step A100: Obtain the resistance value of the atomization assembly 20; determine whether the atomization assembly 20 has a magnetic material 21, if yes, display the first display interface, and enter step A200; if no, display the second display interface, and end operation;

[0110] Step A200: According to the obtained resistance value of the atomization component 20 and the preset corresponding table, output the corresponding power / voltage;

[0111] S...

Embodiment 3

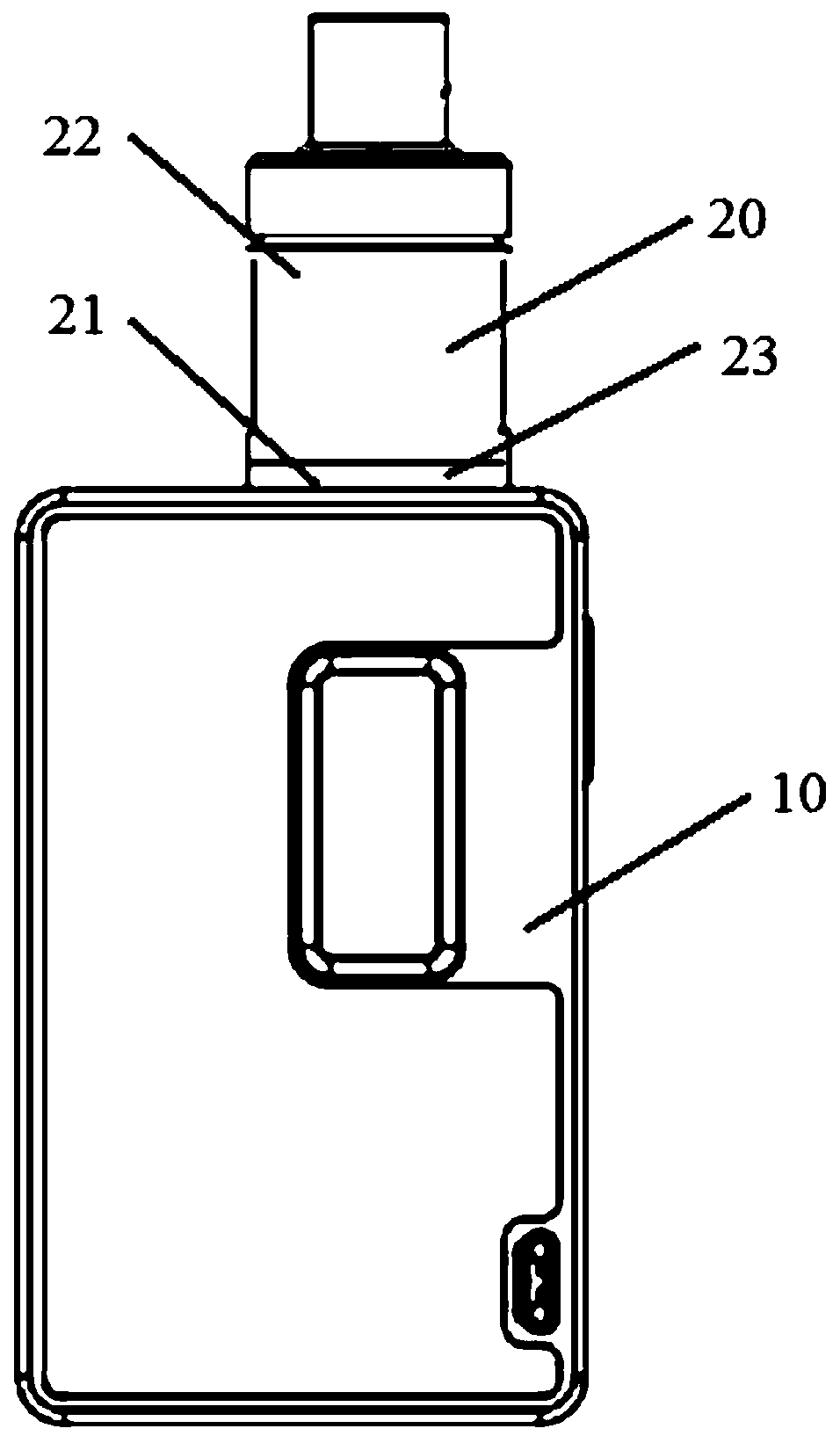

[0114] The structure of the electronic cigarette in this embodiment is basically the same as that in Embodiment 1, mainly including the following differences. One of the differences is that the magnetic sensor 16 is set as a linear Hall-effect sensor IC that can detect the magnetic induction intensity. The second difference lies in this implementation The magnetic material 21 in this example needs to be pre-magnetized, and the amount of magnetization has a corresponding relationship with the size of the resistance value. Due to the difference in magnetic flux, the atomizing component 20 has different magnetic induction intensities, which are detected by a linear Hall effect sensor IC, thereby outputting The magnetic induction intensity signal, and then use the pre-stored magnetic induction intensity-power correspondence table or magnetic induction intensity-voltage correspondence table to control the output power / voltage. The third difference is that the battery assembly 10 doe...

Embodiment 4

[0147] The structure of the electronic cigarette of this embodiment is basically the same as that of the electronic cigarette of Embodiment 1, the difference lies in:

[0148] 1. The atomization assembly 20 includes an atomization head and a smoke outlet pipe. The atomization head includes a heating wire, and the heating wire is a temperature-controllable heating wire; 2. A temperature sensor is set in the smoke outlet pipe; 3. The first The display interface also displays the option of the constant temperature mode, and the user can input the set temperature on the first display interface; 4. The first display interface also displays current atomization temperature information.

[0149] see Figure 8 , an electronic cigarette in this embodiment, including an atomization assembly 20 and a battery assembly 10 connected thereto, the atomization assembly 20 is provided with a magnetic material 21, and the battery assembly 10 includes a magnetic material 21 for identifying The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com