Mixing and dispersing equipment

A dispersing and equipment technology, applied in the field of online flushing, mixing and dispersing equipment, can solve the problems of easy caking and expansion, prolong working time, and the material cannot directly reach the dispersing chamber, etc., and achieve the effect of short contact time and rapid shear dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments and drawings. In the following description, more details are set forth in order to fully understand the present invention. However, the present invention can obviously be implemented in many other ways different from the description herein. Those skilled in the art can make similar promotion and deduction according to actual application conditions without violating the connotation of the present invention. Therefore, the content of this specific embodiment should not limit the protection scope of the present invention.

[0024] It should be noted that the drawings are only examples, they are not drawn on the condition of equal proportions, and should not be taken as limiting the scope of protection actually required by the present invention.

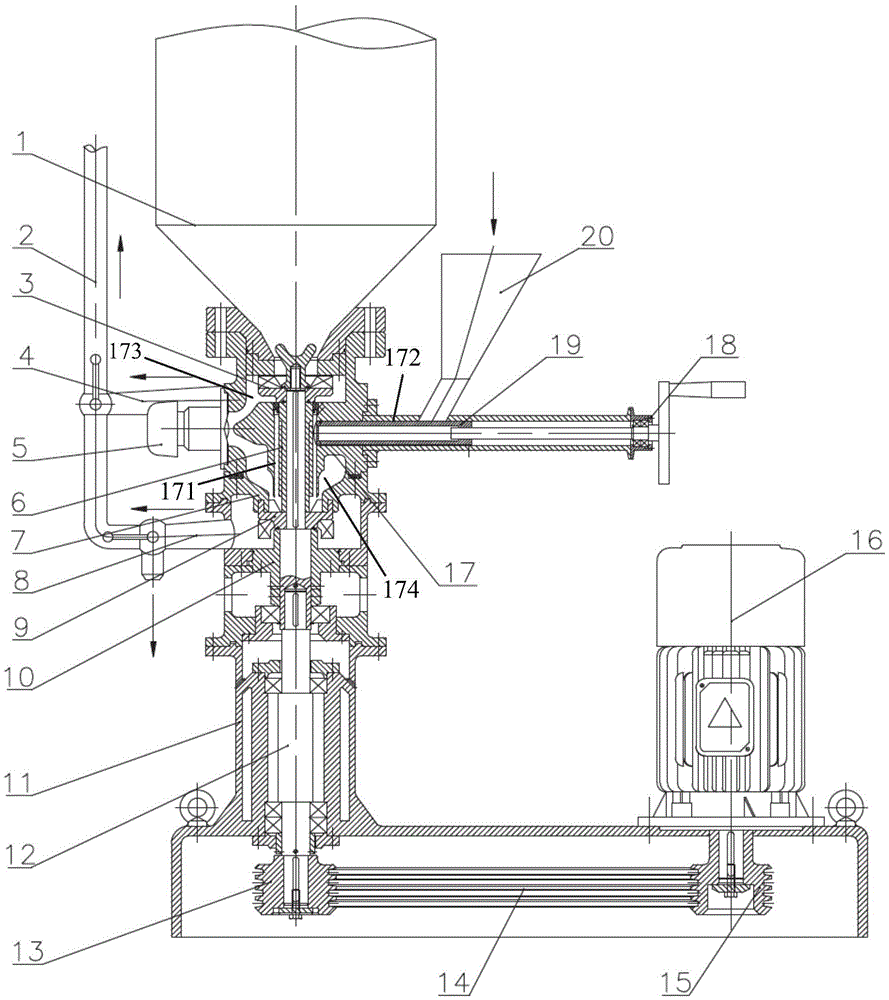

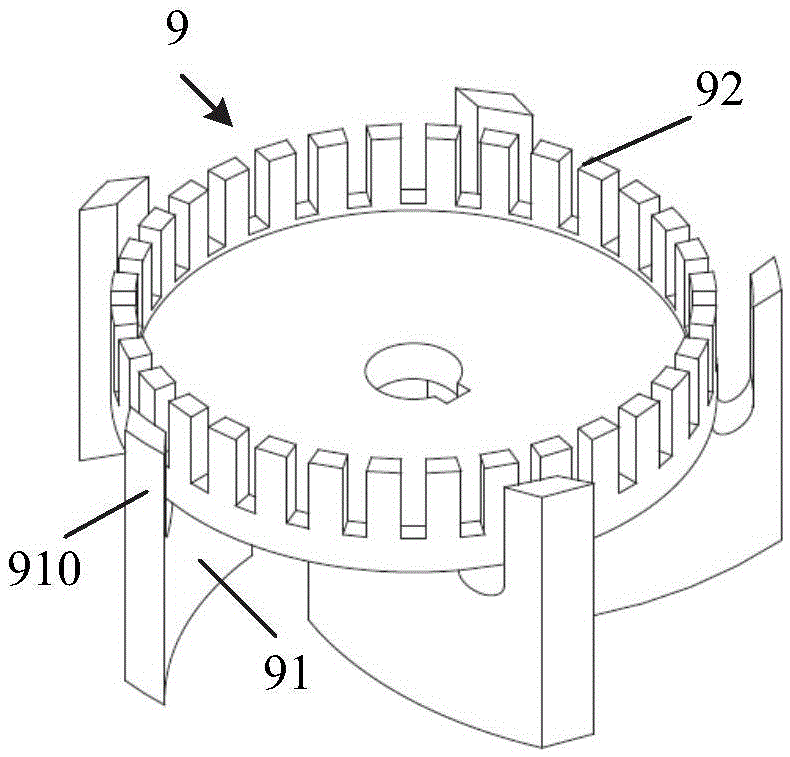

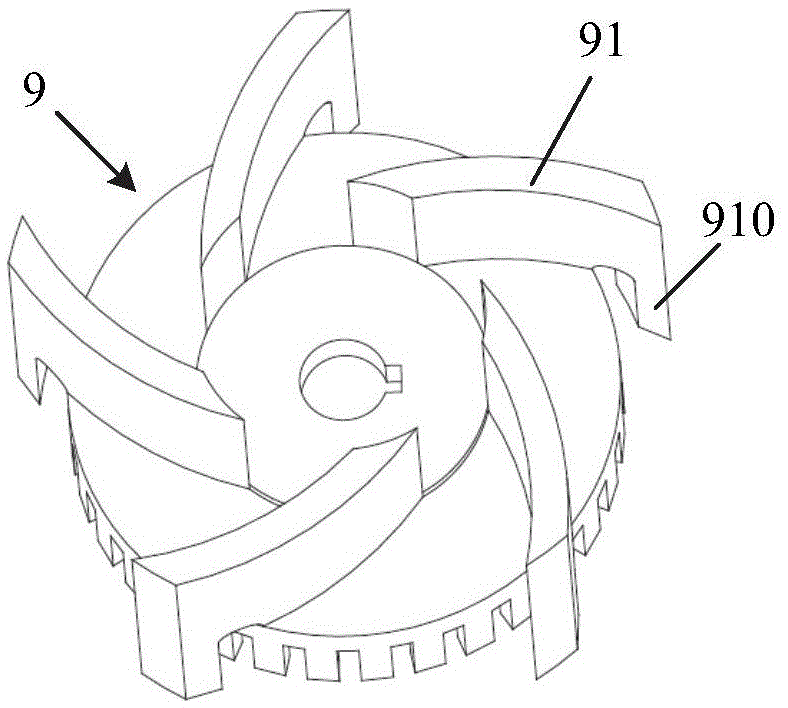

[0025] Such as figure 1 As shown, the mixing and dispersing equipment includes a dispersion cavity 17, a feed container 1, a hopper 20, a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com