Plasma arc rotational conveying device

A plasma arc and rotary conveying technology, applied in the direction of plasma, electrical components, etc., can solve the problems of output arc burning and arc length can not be effectively controlled, achieve short contact time, improve the adaptability of coal types, and improve the fuel saving effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

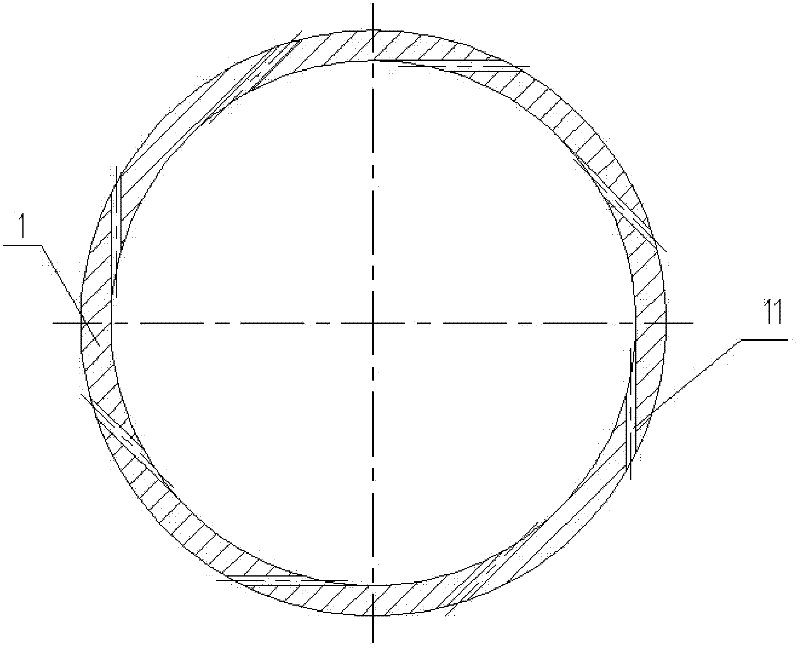

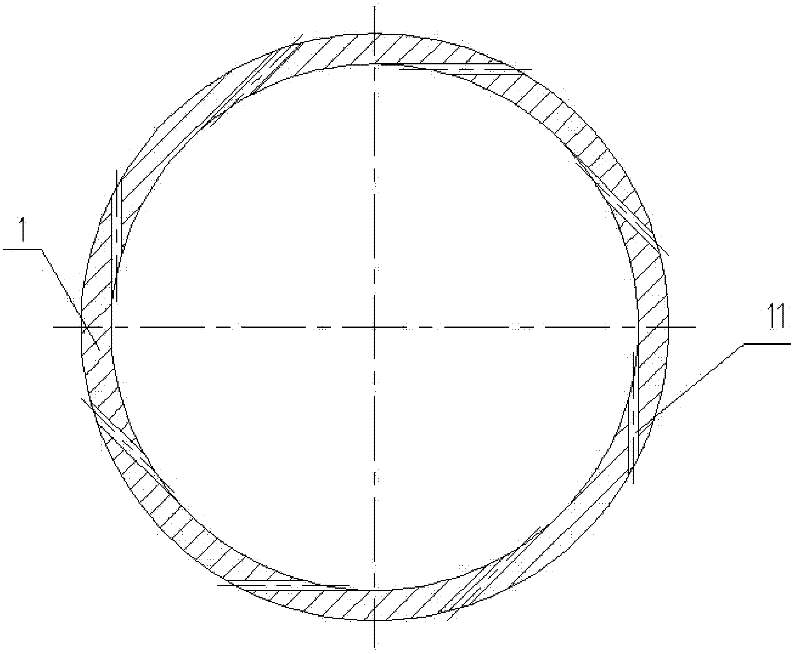

[0016] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] like figure 1 As shown, the plasma arc rotary conveying device described in the present invention includes a circular ring, which is made of high-temperature resistant and magnetically conductive material, and more than two guide holes are evenly distributed on the circular ring. There are eight diversion holes in the drawings; and the axes of the diversion holes are inclined to the circumference of the ring. The tangential angle between the diversion hole and the circular surface is 30 degrees Celsius or 15 degrees Celsius.

[0018] When in use, the annular piece of the present invention is connected between the anode sleeve and the insulating sleeve of the plasma generator, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com