Preparation method of injection molding mold and ceramic sheet, mobile phone cover plate and mobile phone back plate

A technology of injection molding and ceramic sheets, which is applied in ceramic molding machines, mold fixtures, mold auxiliary parts, etc., can solve problems such as increasing energy consumption, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

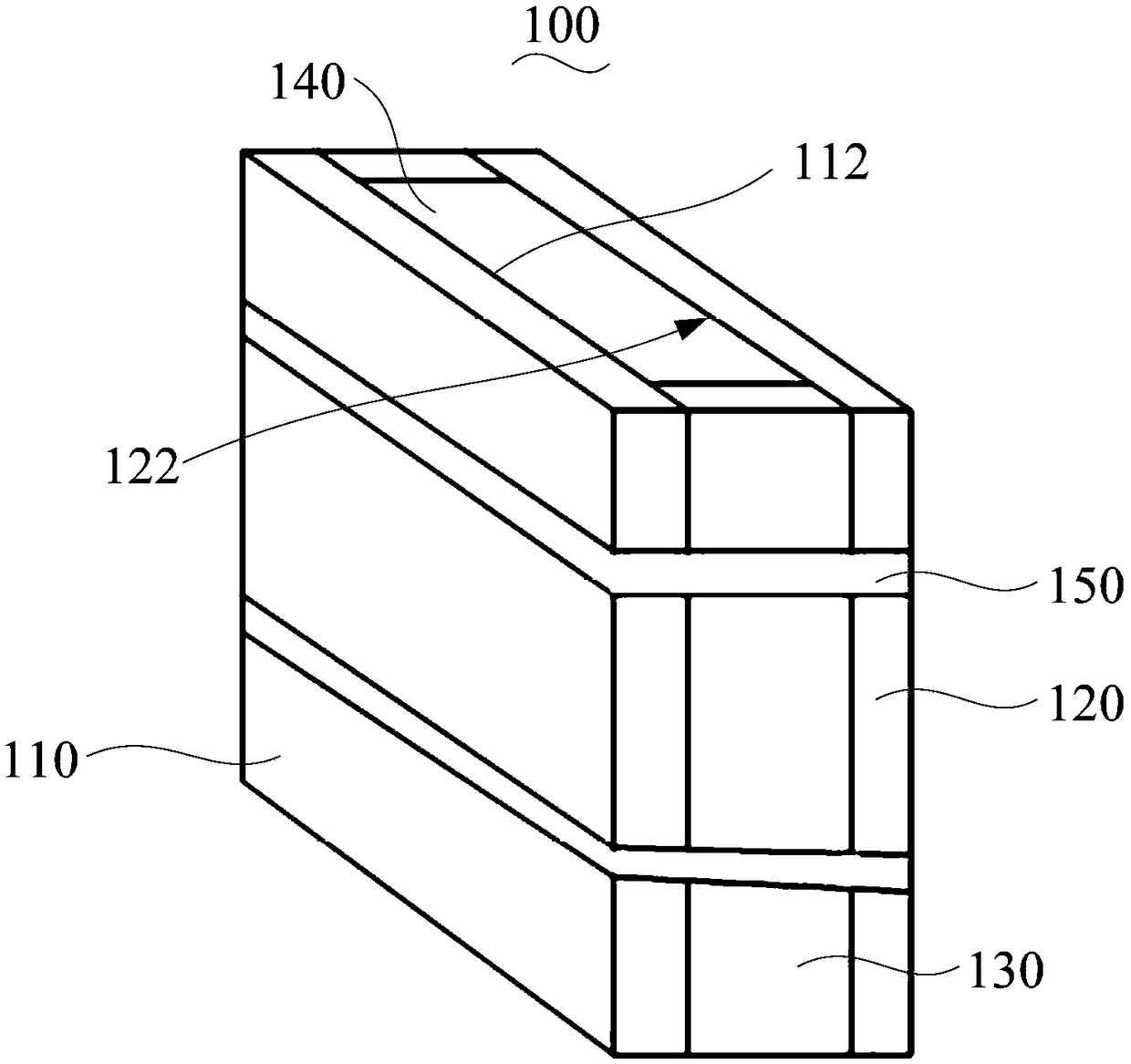

Image

Examples

preparation example Construction

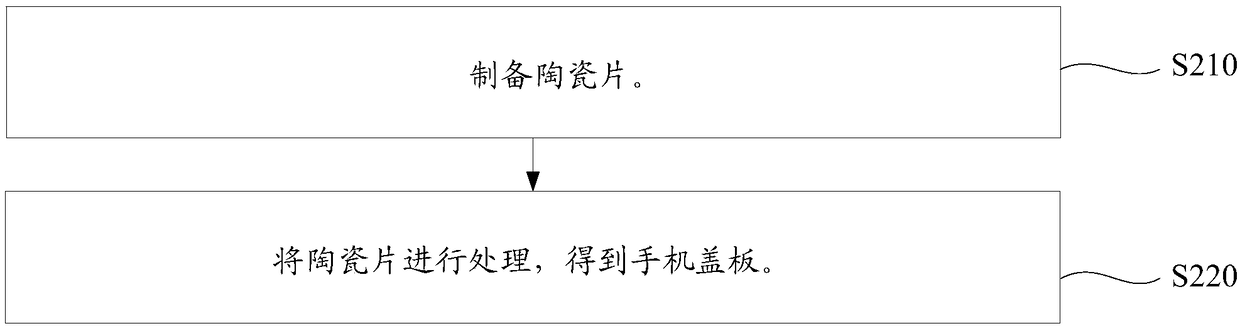

[0041] like figure 2 Shown, the preparation method of the mobile phone cover plate of one embodiment, comprises the following steps:

[0042] Step S210: preparing a ceramic sheet.

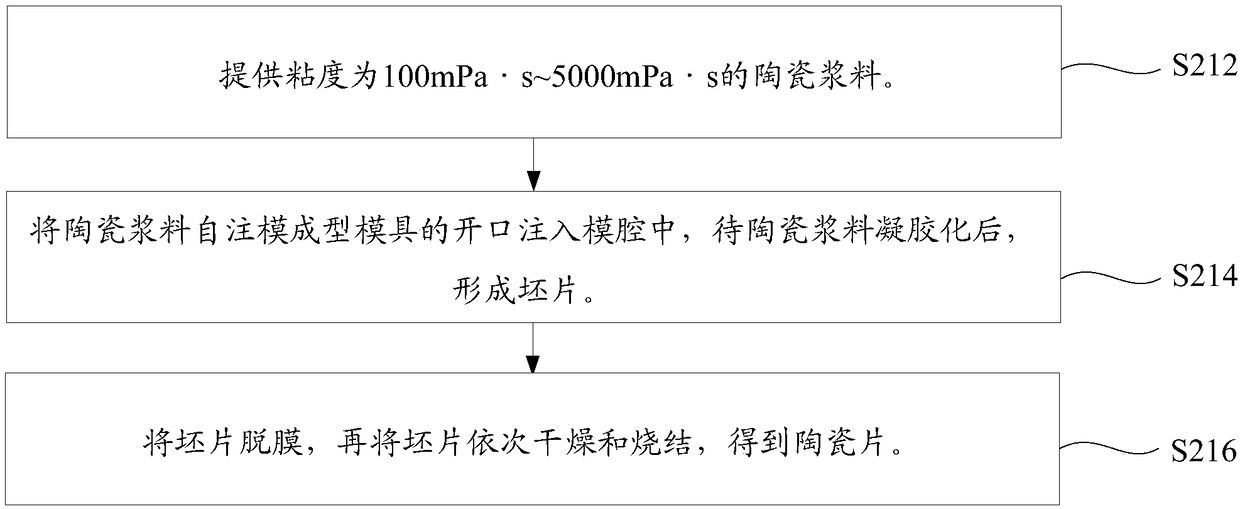

[0043] Among them, such as image 3 As shown, the preparation method of the ceramic sheet in step S210 is as follows:

[0044] Step S212: providing a ceramic slurry with a viscosity of 100 mPa·s˜5000 mPa·s.

[0045] In this example, the preparation steps of the ceramic slurry are: mixing organic monomers, crosslinking agents, dispersants, solvents and ceramic powders, and then adding catalysts and initiators to form ceramic slurry.

[0046] Wherein, the step of mixing the organic monomer, cross-linking agent, dispersant, solvent and ceramic powder is specifically: mixing the organic monomer, cross-linking agent, dispersant and solvent, and adjusting the pH value to 9-10 to obtain Pre-preparation liquid: add ceramic powder to the pre-preparation liquid and mix, then add catalyst and initiator ...

Embodiment 1

[0070] The preparation process of the ceramic sheet of the present embodiment is as follows:

[0071] (1) Stir and mix acrylamide, N,N'-methylenebisacrylamide and ammonium polyacrylate with deionized water, adjust the pH value to 9 with ammonia water, and obtain a pre-preparation solution, wherein, in the pre-preparation solution , the mass percentage of acrylamide is 15%, the mass percentage of ammonium polyacrylate is 3%, and the mass ratio of acrylamide to N,N'-methylenebisacrylamide is 25:1.

[0072] (2) After mixing 3 / 5 of the zirconia powder with the pre-prepared solution for 30 minutes, add the remaining 2 / 5 of the zirconia powder, continue ball milling for 21 hours, and then vacuumize and degas for 20 minutes , and then, under the condition of 25° C., the catalyst and the initiator were sequentially added and stirred for 1 minute respectively to obtain a ceramic slurry with a viscosity of 100 mPa·s. Wherein, the catalyst is N,N,N',N'-tetramethylethylenediamine, and th...

Embodiment 2

[0078] The preparation process of the ceramic sheet of the present embodiment is as follows:

[0079] (1) Stir and mix acrylamide, N,N'-methylenebisacrylamide and ammonium polyacrylate with deionized water, adjust the pH value to 9 with ammonia water, and obtain a pre-preparation solution, wherein, in the pre-preparation solution , the mass percentage of acrylamide is 15%, the mass percentage of ammonium polyacrylate is 3%, and the mass ratio of acrylamide to N,N'-methylenebisacrylamide is 25:1.

[0080] (2) After mixing 3 / 5 of the zirconia powder with the pre-prepared solution for 30 minutes, add the remaining 2 / 5 of the zirconia powder, continue ball milling for 18 hours, and then vacuumize and degas for 20 minutes , and then, under the condition of 22° C., the catalyst and the initiator were sequentially added and stirred for 1 minute respectively to obtain a ceramic slurry with a viscosity of 5000 mPa·s. Wherein, the catalyst is N,N,N',N'-tetramethylethylenediamine, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com