Charge and discharge control method of power battery

A charging and discharging control, power battery technology, applied in the direction of secondary battery charging/discharging, battery/fuel cell control device, control device, etc., can solve the problems of poor charging characteristics, difficult to fully charge the battery, etc., to prolong the service life , improve stability and reliability, and avoid overcharge or overdischarge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The BMS control of the battery management system obtains the SOC range of the battery in real time, predicts the maximum charge and discharge current allowed by the battery, and sends these limits to the vehicle controller, which controls the charge and discharge current to not exceed the allowable limit value. Thereby avoiding overcharging or overdischarging the battery, and incorrect charging causing the worst permanent damage to the battery.

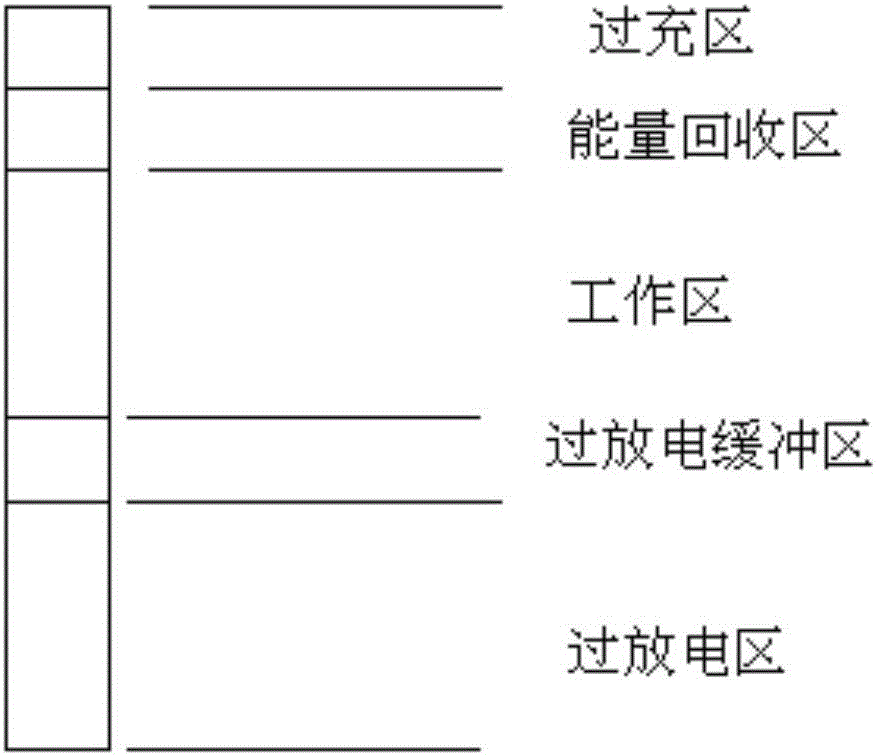

[0030] The SOC range of battery work is defined as: overcharge area, energy recovery area, work area, over-discharge buffer zone, and over-discharge area. Set 40% to 70% SOC as the working range; 30% to 40% SOC as the discharge buffer zone; 70% to 80% SOC as the energy recovery range; >80% SOC as the overcharge range; 0, discharging).

[0031] The charging system is working, and the following steps are cyclically executed according to the set frequency (the timing is 50ms for comparative control):

[0032] First read the esti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com