Method for determining largest use current of lithium-ion battery

A power battery, lithium-ion technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problem of inaccurate determination of the maximum charging and discharging current of lithium-ion power batteries, to ensure service life, avoid overcharging and Overdischarge, easy to grasp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

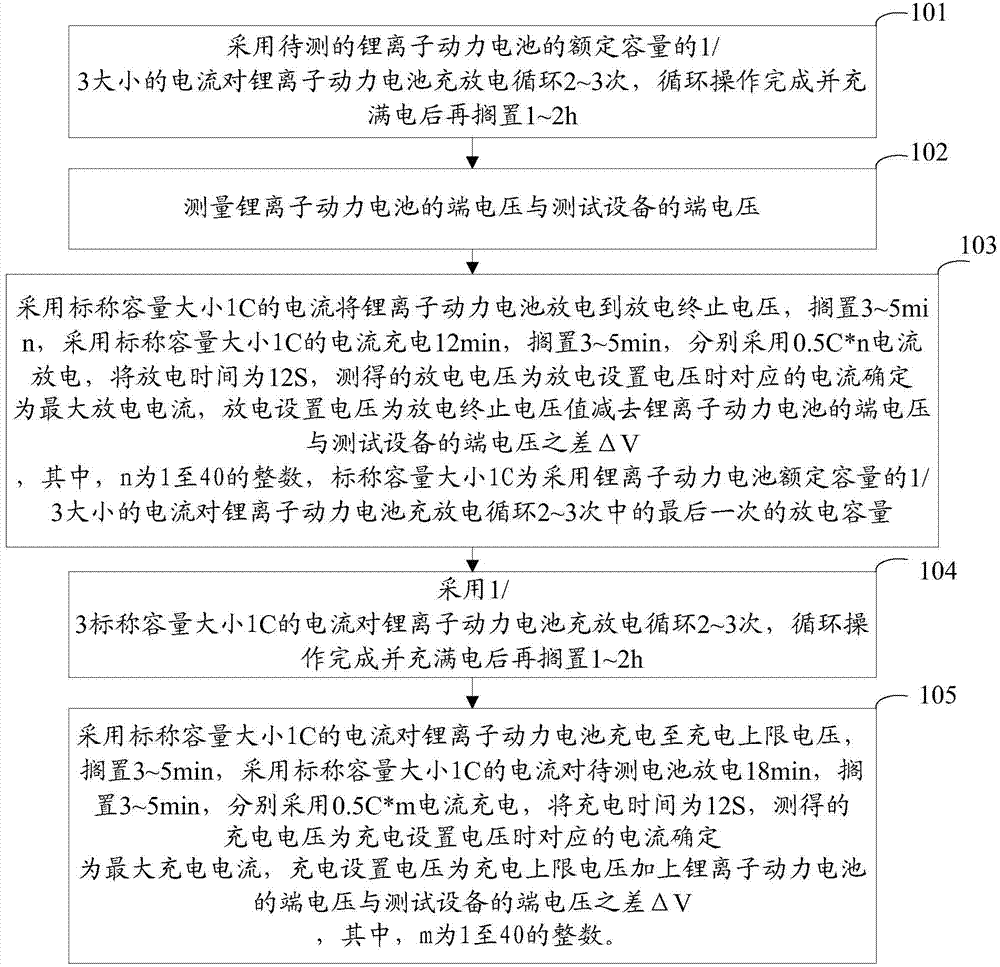

[0033] The embodiment of the present invention provides a method for determining the maximum use current of a lithium-ion power battery, see figure 1 , methods include:

[0034] Step 101: Use a current of 1 / 3 of the rated capacity of the lithium-ion power battery to be tested to charge and discharge the lithium-ion power battery for 2-3 times. After the cycle operation is completed and fully charged, it is left for 1-2 hours.

[0035] Step 102: Measure the terminal voltage of the lithium-ion power battery and the terminal voltage of the test equipment.

[0036] Step 103: Use a current with a nominal capacity of 1C to discharge the lithium-ion power battery to the end-of-discharge voltage, put it aside for 3-5 minutes, charge it with a current with a nominal capacity of 1C for 12 minutes, put it aside for 3-5 minutes, and use a current of 0.5C*n respectively For discharge, the discharge time is 12S, and the measured discharge voltage is the discharge setting voltage, and the c...

Embodiment 2

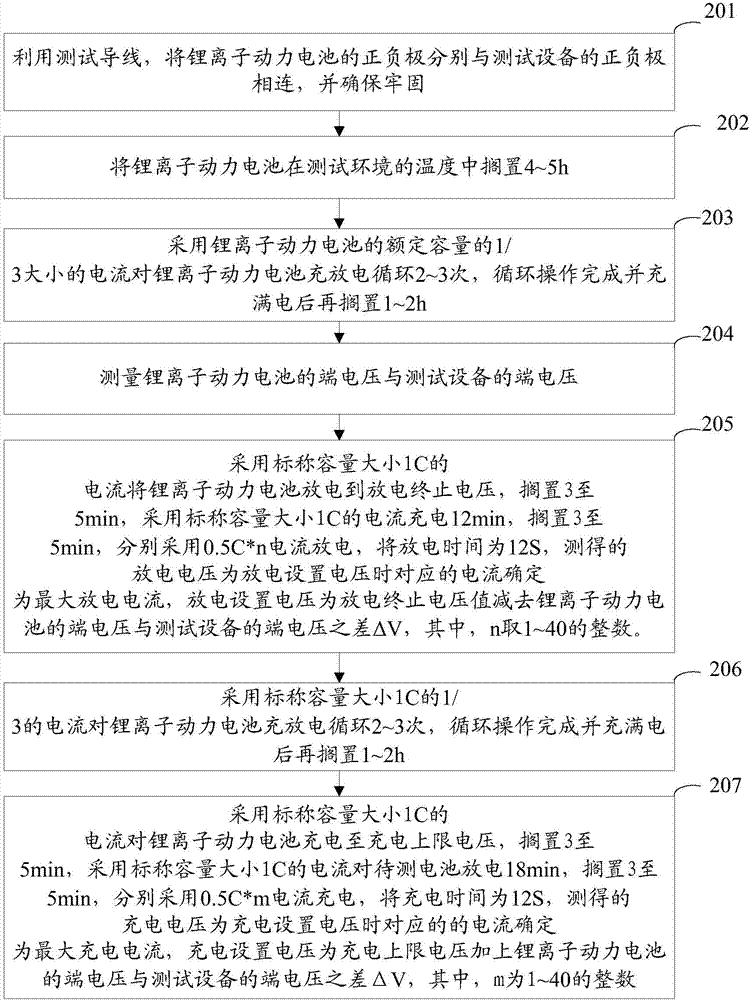

[0042] The embodiment of the present invention provides a method for determining the maximum use current of a lithium-ion power battery, see figure 2 , the method includes:

[0043] Step 201: Connect the positive and negative poles of the lithium-ion power battery to the positive and negative poles of the testing device respectively by using test leads, and make sure they are firm.

[0044] Among them, the test equipment is a high-precision lithium-ion battery test equipment that converts alternating current to direct current. In this embodiment, the current resolution of the test equipment is 0.0001A, the voltage resolution is 0.0001V, the data recording resolution is 0.001S, and the maximum range current of the test equipment is 15 to 20 times the actual discharge capacity of the lithium-ion power battery .

[0045] In actual implementation, the resistance of the test lead is also required to be less than or equal to 10mΩ, that is, the contact internal resistance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com