An automatic detection receiving equipment and automatic packaging machine

A technology of automatic detection and detection mechanism, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of inability to meet production needs, low production efficiency, slow detection speed, etc., saving manpower, improving production efficiency, and simple operation. handy effect

Active Publication Date: 2022-06-03

JIANGSU CHUANGYUAN ELECTRON CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Through manual detection, that is, manual detection by naked eye observation and judgment, the error is large; and it needs to be detected one by one, the detection speed is slow, manpower is wasted, the production efficiency is low, and the production demand cannot be met.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

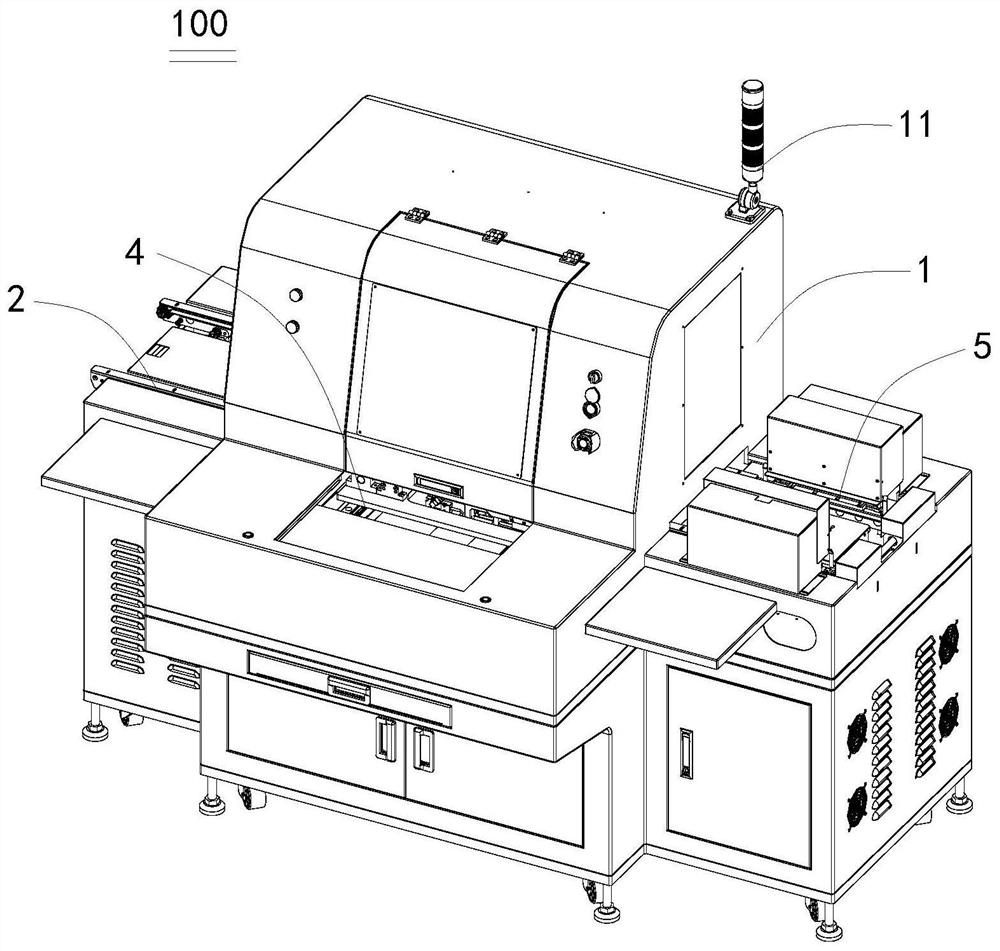

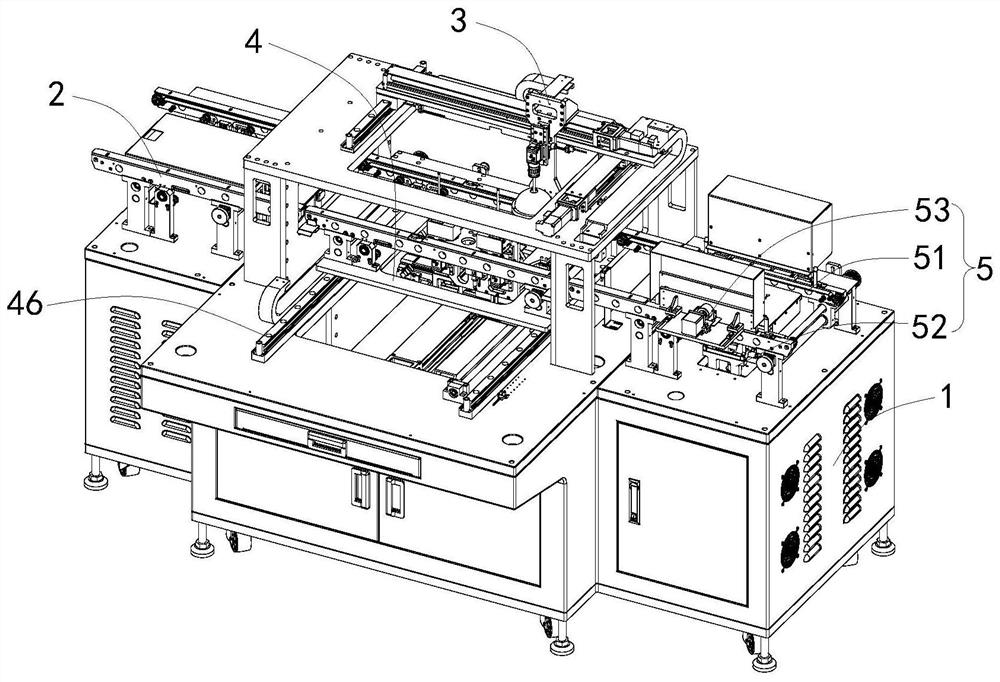

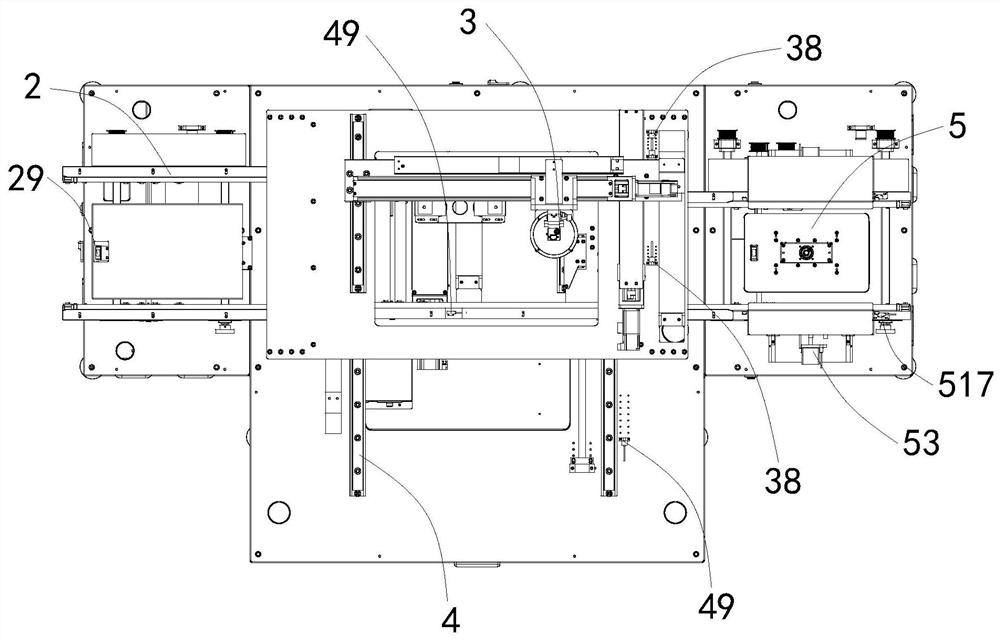

The invention provides an automatic detection and receiving device and an automatic packaging machine, including a frame, a feeding mechanism arranged on the frame, a detection mechanism, a feeding feeding mechanism and a discharging mechanism; the feeding mechanism, The conveying feeding mechanism and the discharging mechanism are sequentially docked, and the detection mechanism is located above the conveying feeding mechanism. The automatic detection and receiving equipment is used to detect and receive the product. The feeding mechanism feeds the material. After the transmission and feeding mechanism receives the product, the testing mechanism performs detection. When the product is detected as qualified, the product is discharged by the discharging mechanism. Recycling, when it is detected as an unqualified product, it will be fed at the feeding feeding mechanism, and then the product will be discharged and recycled by the feeding mechanism, which realizes the automatic detection and receiving of the product, the operation is simple and convenient, and the automatic production is realized , saving manpower and improving production efficiency.

Description

A kind of automatic detection and receiving equipment and automatic packaging machine technical field The present invention relates to automatic machining technology field, relate in particular to a kind of automatic detection material receiving equipment and automatic Packing Machine. Background technique In machining, especially in the production process of electronic products, after product processing is completed, it is necessary to carry out Packaging, before the product is packaged, the processed product needs to be tested, and then the material is received, that is, after the test is qualified, the load needs to be The trays are neatly stacked. Usually, multiple products are stored on a carrier tray, and the products need to be tested, including whether there is a shortage of materials and products. for damage. Through manual detection, that is, manual detection through visual observation and judgment, the error is relatively large; And it needs to be test...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B57/04

CPCB65B57/04

Inventor 严胜旺

Owner JIANGSU CHUANGYUAN ELECTRON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com